The gate is an entrance opening on demand for transport, which is locked with a lock. The owners make sliding, folding, swing gates with their own hands. They can be mechanical or automatic opening. A gate is placed in the sash, the material of the canvas is corrugated board, wood, sheet metal, polycarbonate, etc. The gate is placed in the garage, in the fence of a summer cottage or in the fence of the courtyard of a residential building.

Varieties of gates for a private house

The model is chosen taking into account the constructive variety, dimensions, taking into account the weight of the canvas and pillars, the need for remote control. The price of automation adds value to the gate. A specialist is required to install the device, the operation of the device will require electricity costs. There are modern automatic devices that are powered by solar panels.

The main types are used:

- roll;

- sliding;

- swing;

- folding and swing-out.

The design of the gate structure must match the style of the landscape and the residential building. Therefore, the owners prefer to make gates for a private house with their own hands in order to emphasize the beauty of the entrance group.

The design requires ease of use, strength and reliability, in addition to appearance.

Swinging

The classic version that is used most often. Two doors open inward, outward, sometimes pendulum hinges are used to swing open in both directions. The canvas is represented by a rigid frame made of metal or wood, inside which an infill of various materials is installed. Outdoor opening takes into account the sidewalk in front of the yard, while inside there should be room to close after the vehicle enters.

Modern sashes are of considerable height and width, since the automation can easily cope with such dimensions without the risk of injury to a person.

There are 3 options for the arrangement of the drives for automatic opening:

- linear;

- lever;

- underground.

The worm (linear) method is widespread, in which the rod (piston) lengthens, shortens and moves the door leaf. Such drives are hydraulic or mechanical.

Sliding

Self-made sliding gate design is gaining popularity as it does not require space in front and behind the gate to open. The doors are made in the form of a steel frame with spacers and corner braces for rigidity. Inside, they put a lining of a metal profile, wood, sandwich panels.

The advantages of sliding systems:

- in case of snow drift, they do not require cleaning the area in front of the yard for opening;

- there is no limitation in size, the limit exists only along the length of the fence, past which the shutters move;

- there is no upper frame, a car of any height can pass.

Of the shortcomings, they note the need for a foundation, where guide girders for rollers are attached. There are designs with a cantilever opening option, when the beam is placed on the fence. The option with the installation of a beam across the passage is not used due to transport restrictions in height.If the gate has one large leaf (single-leaf types), they are called sliding doors.

Swing-out

The constructions are installed in private yards and household facilities. The system includes a frame, curtain and horizontal guide beams under the ceiling. The frame and sashes are made of galvanized metal profiles without a thermal profile inside.

The frame elements are connected by a screw method, and special connecting parts are provided for the web profiles. In insulated versions, PVC plates are inserted into the sash. The curtain is a continuous single section that tilts during opening, then enters the garage.

Features of tilt and turn gate systems:

- resist hacking;

- take up minimal space when closed and open.

Burglary resistance is ensured by the integrity of the sash with the proviso that high-quality coating materials have been used.

In the process of opening, the leaf first protrudes slightly forward with the lower part, which must be taken into account when the machine stops at the gate.

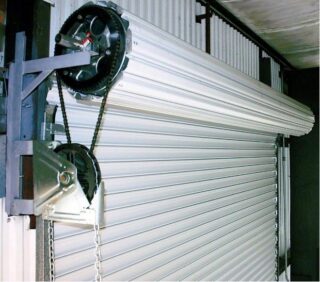

Roll

In this scheme, the canvas is rolled up and wound on a shaft, which is located at the top in a protected box. The roll-up version protects the door openings from unauthorized access. Simple gate design is a kind of roller shutter.

Advantages of roll-to-roll schemes:

- additional protection of the door structure from outside access;

- protection from viewing the internal space;

- profitability, easy installation;

- saving space.

The canvas is made of lamellas - strips, which are connected into a single plane by means of special edges. Inside, the longitudinal elements are hollow or filled with cellular insulation. Rolls are mounted so that the canvas opens outside or inside the garage. You can make the gate with your own hands, the work will take a little time.

Foldable

In such systems, the canvas is composed of sandwich panels, which are attached to each other with special hinges. The door leaf moves along horizontal and vertical girders installed on the inside of the front wall above the opening and continues on the ceiling. Opening means the successive movement of the sections to the ceiling.

Positive aspects of folding varieties:

- sectional gates for summer cottages are placed in any span and opening;

- the canvas protects against sounds and heat loss;

- the design is safe and easy to use;

- has a beautiful and modern appearance;

- characterized by long-term operation (up to twenty years).

Folding gate leaves do not interfere with the movement of the car, save space in the garage. Provide for easy and quick remote opening, closing, reliably protect against burglary. There is a possibility of manual opening due to the installation of compensation springs.

Materials for self-production of swing gates

In the manufacture of swing gates, the owner's wishes for the appearance and his material capabilities are taken into account.

The most popular types of stitching:

- wooden;

- corrugated board.

Stitches differ in technical characteristics and qualities, so the choice is not difficult. The combination principle is applied. Profiled sheet and wood go well with forged elements. Such additions make the gates to the dacha heavier and cost a lot of money. Opt for heavy duty hinges and automatic appliances. Under the sash with many forged parts, you need to build foundations.

Tree types

The material is suitable for self-production and installation work, since it is easily processed, sawn and joined into a structure.Most often, construction is carried out without special and expensive equipment, but there are exceptions depending on the type of tree.

Oak gates are the most expensive of all types. The material is hard, so you can't do with a hand saw, you need a circular one. Oak canvases are durable, do not collapse from blows. The wood contains tanning components that protect the structure from decay. There are more than 20 natural looking shades and colors on sale for choosing a gate option.

Conifers also resist moisture due to the presence of resinous substances in the composition, which, in some cases, are released on the surface of the lumber. Wood has a beautiful texture, pattern, color, and is much cheaper than hardwood.

Pine has increased strength compared to spruce, but dries out more. Spruce shrinks less, but absorbs more water from the soil and atmosphere. Coniferous larch has a high density, almost does not rot, has a beautiful pattern of fibers, requires only varnishing without painting.

Varieties of professional sheet

The corrugated board acts as a lining in the manufacture of do-it-yourself metal swing gates. Corrugated sheets are placed in a frame made of a profile pipe, corner, channel.

Types of corrugated board:

- steel uncoated;

- hot-dip galvanized;

- hot-dip galvanized with a polymer outer layer;

- made of chromed iron, copper, aluminum.

The first type is almost never used, since it corrodes quickly. The choice of a profiled sheet for the gate depends on the thickness of the material and zinc coating, the type of sprayed polymer and its thickness.

For the construction of gates, sheets with the marking C (wall) and HC (reinforced for the roof and walls) are used. In height, they take a corrugation of 8 - 21 cm, material with a higher height goes to the roofing, fixed formwork.

Design features

Details and structural elements:

- vertical support posts;

- frame for installing the panel material;

- sewing layer;

- hinges, latches, locks, automatic control device.

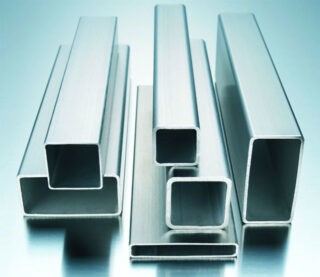

The frame is made of a square or rectangular tube. The size of the section depends on the dimensions of the span and the height of the pillars.

Use the size by weight of one canvas:

- up to 150 kg - pipe 80 x 80 with a wall thickness of 4 mm;

- 150 - 300 kg - rolled sections 100 x 100, shell thickness 5 mm;

- More than 300 kg - pipe 140 x 100, thickness 5 mm.

The doors are hung on pillars made of concrete, brick, wood, metal. Hinges are chosen with or without such a function from high-quality material, locks are installed electronic, electromechanical, mechanical.

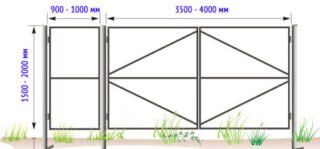

Drawing with standard dimensions

It is necessary to make a drawing of the gate or a sketch on paper indicating all dimensions. The dimensions of the canvases in height are determined so that there is a technical gap from below, designed for a small snow drift (10-15 cm from the ground). The clearance reduces wind load as it reduces windage.

The frame is welded according to the project so that the sheathing material becomes into it without cutting. Cutting increases labor intensity; after adjustment, residues are obtained, which are thrown away. A small gap (3 - 5 mm) is made between the flaps in order to level out some displacement of parts.

Standard dimensions provide for a door width of 3.5 - 4.0 m, so that cars and trucks can easily pass through. It is possible to make a structure with a greater width, but then the cost of construction will increase, and the benefits are almost not added. Five meters or more is chosen in exceptional cases, if there are obstacles at the entrance, and there is no other place for the gate structure.

Tools for the job

To mark and coordinate the plane, verticality during welding and installation, you will need a tape measure, a level, a building corner, a pencil or a core.

Other tools:

- electric or arc welding with a set of consumables;

- screwdriver, Phillips screwdriver

- angle grinder (grinder) with a circle on steel and a disc for cleaning;

- hammer, pliers;

- drill.

Excavation work will require a bayonet shovel, crowbar, ax. For mixing concrete, you need a concrete mixer or a trough, a shovel. Painting is performed with a spray gun or take a roller and a brush with a cuvette.

Making swing gates from corrugated board with your own hands

Preparatory work includes site selection, drawing development and surface marking.

The main manufacturing work consists of the following stages:

- digging in pillars;

- fabrication of frames;

- sewing the canvas;

- hanging of canvases on support posts, installation of a lock.

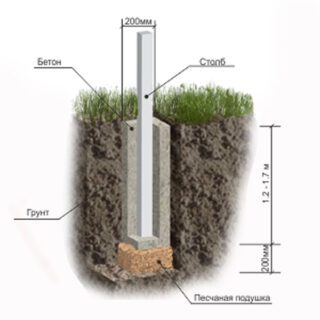

The pillars are dug in to a depth of 50 - 100 cm, sand, crushed stone are placed on the bottom of the pit, and the bedding is rammed. Pillars are placed on the level and concreted. The frame is cooked horizontally on a flat surface or stands. Check rectangularity and flatness, exclude distortions.

The lining is installed using hardware, bolts so that there are no gaps. The lower part of the hinge is welded onto the racks, and the upper part is fixed to the frame. Verify the verticality so that the canvases do not warp when opening. Locks and bolts are welded to the frame of the doors and pillars.

Swing gate

A gate is placed in the canvas to combine the passage and reduce the length of the entrance group. The built-in wicket has the advantages of saving filling material and practicality of use. Additionally, a profile pipe is required for arranging the frame around the perimeter of the structure.

The wicket inside the gate has a threshold and an upper bar, which is not always convenient when people of tall stature pass through. The width of such an opening in the sash is always limited, so it is more difficult for obese people to move around, there is no way to carry hand luggage on a trolley.

The material is selected according to the type of gate filling and the material of the fence. A separate lock and bolt are used to lock the gate. If automatic opening is provided, fixing elements are installed that coordinate the open wicket. So when a person passes, the gate automatics will not work.