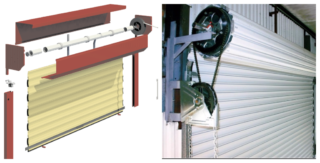

Roller shutters for garage spaces have become commonplace. The leaf of such gates is formed from metal slats and special locks. The movement is parallel to the guides installed on both sides of the opening. When opened, the lamellas rush up. Making roller shutter doors for a garage with your own hands is a very real task if you have an assistant and certain construction skills.

Advantages and disadvantages of roller shutters

Roller shutter gates are often attractive to homeowners for the reason that such a fence helps to save space on the site. It does not “eat up” the usable space in front of the entrance and does not limit the width of the entrance area. In addition, the design has the following advantages:

- compactness, the ability to install in a very limited space;

- no need for regular snow removal when installing swing gates;

- attractive appearance;

- The metal profile protects the interior from dirt, which helps to keep the garage clean.

The downside of the design is the lack of ability to retain heat. When the slats are lifted up, cold air from the street enters the room. In addition, in winter, slats and other structural elements can freeze through. Water accumulates in the cracks and turns into ice; it can be difficult to open the structure. This can be leveled by treating the lamellas with special fluids that prevent icing.

Material selection

To make a rolling gate with your own hands, you need to choose the right material. Steel and aluminum slats are suitable for the garage. The first option is stronger and more reliable, although the material is susceptible to corrosive processes. Such canvases are made from galvanized or painted steel profiles. The material must be treated with anti-corrosion compounds. The advantage of aluminum lamellas is less weight. You can find products with increased strength, the gates of which create increased protection.

There is also a number of materials from which it is possible to make a roll structure, but they should not be used for a garage. Plastic roller shutters are not suitable for this purpose due to exposure to environmental influences and insufficient strength.

Structures from a metal profile with plastic inserts, as a rule, are not used anywhere in private construction. They are purchased for showcases of retail outlets and other places that need frequent ventilation.

Wooden boards are very widely used to create other types of gates, but they are rarely used for roll structures, especially when it comes to a garage.

Preparation for work

Before making a gate, you need to make a drawing of it. You can use ready-made sketches or design the structure yourself. The diagram shows the width and height of the web, the dimensions of the lamellas and the box, the length of the tire. If it is planned to equip home-made gates with automation, the locations of the corresponding devices and the wiring paths are also indicated. In addition, you need to calculate the estimate of the project in advance.

To make a roll gate with your own hands, you will need a hammer drill and an electric drill with a set of several drills that differ in length. Also for work you need a set of screwdrivers. Of the fasteners, you will need anchors 1 cm long, self-tapping screws and dowels. We need tools for measuring and controlling evenness - a building tape and a level.

Installation procedure for roller shutter gates in the garage

It is better to install roller shutter gates from scratch with one or two assistants. Alone, such a volume of work is problematic even with the skills. First you need to install the guides and assemble the frame.

Fastening the guides

Step-by-step instruction:

- a groove is made in the room for installing a spring that supports the control mechanism;

- a box is formed: the body is connected to the sides using aluminum rivets;

- a spring is inserted to the right of the shaft;

- the shaft is connected to the box located on the lintel;

- the frame is applied and the fasteners are marked;

- holes are made and guides are mounted;

- the lace is threaded into the spring;

- the frame is twisted with self-tapping screws;

- the holes are closed with plugs.

Lower and upper holes are supposed to be made at a distance of up to 15 cm from the edge. If this limitation is not observed, the frame may not be firmly attached. In this case, the gate will quickly fail.

Roller shutter installation

When the frame is fixed, they begin to install the canvas. Its ends are fixed from below with a special profile. A pair of holes with a diameter of 6 mm are made in the lower plank. Stoppers are installed in these grooves to support the lamellas. Then the roller shutter is closed with a lid. A roller is screwed on the inside of the lintel. Evenness is controlled by the building level. Upon completion of the work, the smoothness of the blade is tested: it is raised up and lowered.

Automation device

An automatic block can be installed so that the gate can be opened from a certain distance. When connecting an electric drive and other devices, you must strictly follow the instructions in the instructions. The wires are mounted in such a way as to protect them from breaking the integrity of the protective shell and contact with moisture.

Steps for setting and adjusting the gate

To adjust the limit switches for an industrially produced blade, the supplied hexagon is suitable. It is necessary to determine the lowest and highest position of the canvas. They are set thanks to the corresponding switches located on the side of the box. The upper position is adjusted so that one of the slats is in the opening of the guides. The front part of the box is reinforced using self-tapping screws. To assess the sliding quality of the leaf, you need to open and close the gate several times. If the result is satisfactory, remove the protective film from the lamellas and wipe off the dust.

Door opening installation

Before installing roller shutters, the opening must be prepared. The wall should be monolithic, without voids. If it is made of bricks with slots, or foam blocks, the opening is edged with a metal corner with parameters 75x75 mm.

Finishing before work must be completed.

If there is a 30-40 cm lintel inside the room, and there are no pipes or other structures in the gate installation area, the canvas can be placed inside the garage. Sometimes an invoice installation of roller shutters at the entrance is made. In this case, stable columns must be prepared in advance.