Accordion gates for summer cottages - a design that is extremely convenient in confined spaces. They are also installed by the owners of ordinary private houses. The gate can also close the garage opening.

Description and advantages of folding gates

Folding gates for summer cottages are metal and wooden. Sometimes components made from both materials are combined. The partition consists of horizontally or vertically arranged shutters connected to each other. When the gate is opened, these elements add up. Structures can be supplied with rails or have a console. Sometimes they are equipped with automation.

To make a folding gate with your own hands, you need to have an idea of their device. Swing elements are made of panels fitted with flexible spacers (usually rubber) to facilitate movement. They are connected using awnings. Often hinges are mounted on the supporting frame, connecting the elements to each other. In this case, they open at a right angle, and close at a full angle.

Sandwich panels are widely used for the production of doors. This is due to their ability to provide heat and sound insulation, as well as their low price.

The panels move along the guides in which the rollers are built. In many systems, these parts are only present at the bottom, but sometimes they are also mounted on top. Sometimes a wicket is installed in the gate.

Making folding swing gates with your own hands will not be difficult without special skills. They are also very easy to use. Ease of use remains in winter as well: the system can be easily opened if there are significant snow masses on the territory.

The use of a folding structure (for example, two-leaf) helps to minimize the loss of usable area of the site. The material of the panels tolerates temperature fluctuations and other environmental influences well. Also, the structure does not create a large load on the floors. Such gates can serve for a long time.

Varieties of devices

One of the most common types of such gates is harmonic... The system uses vertically mounted hinged panels with top and bottom seals. The movement of the gate is accompanied by the sliding of the rollers along the guide. Such a system is attractive because it does not “eat up” the useful space of the site. When creating an "accordion", it is important that all strips have identical dimensions to each other. The number of elements must also be determined in advance. It is recommended to prepare a drawing, which shows a diagram of the structure of the gate and the dimensions of the main elements.

Sectional the gate consists of horizontally arranged panels. Unlike the previous type, their guides are not at the top and bottom, but on the right and left. At the same time, they go to the ceiling. When the structure is opened, its elements move along the guides and subsequently rise to the ceiling. These models have excellent performance characteristics - durability, long service life, the ability to isolate the interior from extraneous noise. But they are only suitable for rooms of sufficient size and area.

Roll models consist of small-width planks made of plastic or metal and forming a canvas of sufficient flexibility. As in the rest of the options, the elements move along the guides. But as it moves, the web is wound onto a special drum located in the upper part of the opening. The system is easy to install, compact, and less expensive than other types of doors. It has a neat appearance and protects the room from dust and clogging. But such gates also have a disadvantage: they are easy to crack.

How to make an accordion gate with your own hands

Sometimes homeowners prefer to install prefabricated structures. However, the installation of sliding and other folding gates can easily be realized on our own.

Preparatory work

Before you start purchasing raw materials for the construction, you need to prepare its sketch. The number of sections and their dimensions depend on the width of the opening. All elements must have the same dimensions. The drawing indicates the dimensions of the racks, panels, gaps between them, the point of installation of fasteners.

When preparing the project, the characteristics of the surrounding space are also taken into account - the relief of the earth's surface and the width of the roadway suitable for the fence. The dimensions of the gate usually correspond to the height of the fence or slightly (maximum 0.5 m) exceed it. Before making a drawing, it is important to determine the width of the vehicle's entrance area. The radius of its rotation also matters. The smaller the distance between the carriageway and the entrance area, the wider the structure will be. If the distance is large enough, the width can be 3-4m for a passenger car. For a truck, it will be larger. If the entry area is small, the width is determined by a practical method. To do this, you need to try to enter the site several times and then leave. In areas where the goal line intersects the track, 0.2-0.3 m is added.

Materials and tools

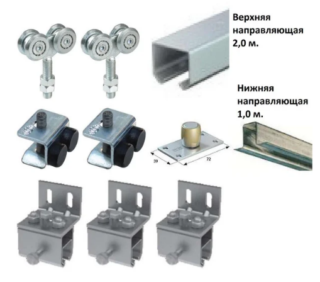

To make an accordion gate with your own hands, you need to prepare two metal channel beams in the shape of the letter P. You will also need rollers equipped with bearings: they help the shutters move along the guide.

For work, you will need the following tools:

- construction tape and level for measuring and checking evenness;

- welding machine for 220 V;

- screwdriver for installing fasteners;

- grinder for cutting elements and cleaning welded seams;

- electric drill.

Facing material can be iron sheets (preferably galvanized) or corrugated board. For insulation, foam or mineral wool is suitable. For the frame, you also need a metal pipe with a cross section of 2.5 cm.

Installation of supports

When installing the door for the first time, it is required to reinforce the opening with channels. The latter should occupy only the area of the opening where the rollers are not planned to be located. A metal paw must be welded to the bottom. The channels are fixed with anchors.

To install the support, you need to measure the height of the opening and subtract the thickness of the guide from it. This value is noted on the supporting channel elements and cut with a grinder. Metal corners are welded to the lower areas. The channels themselves must be installed on the sides and at the bottom of the opening. For this, a welding machine is also used. Then the cross beams are mounted. At the bottom, they are welded to the corners of the channels, and connected to the top of the opening by means of anchors. The corner where the rollers are supposed to be mounted is attached to the upper beam above the structure.

Assembling the frame

The elements that make up the canvas must have the same dimensions. Having cut the tubes to the required sizes, they are placed on a flat surface and the frame is welded. To make it stronger, it is recommended to use diagonal and horizontal jumpers.

Installation of the canopy

This procedure requires bearing hinges.They are purchased at the rate of a pair for each section. They must be fixed so that the canvas folds like an accordion.

Fastening rollers and guides

The guide is welded into a horizontal beam placed on the posts. To install the roller, a plate is welded to which the pin is attached (before this, it must be hardened). The free end is bent at a right angle and inserted into the roller. Nuts are used for fixing.

Sheathing of the structure

Sheathing sheet material can be fastened with self-tapping screws, rivets or a welding machine. The gaps between the panels are covered with a tarpaulin. It is also important to consider where the lock will be located (it can be suspended or mortise).