A metal mesh fence is a simple and inexpensive construction to protect the site from uninvited visitors. The owners build a fence from a chain-link mesh with their own hands, since the work is not difficult. The fence allows you to view the surroundings of the site, see the events taking place on the street. Such fences are placed inside the yard to separate areas for keeping animals, poultry, and to limit the area of management.

Basic information about the netting

Structural material is produced on machines that twist wire spirals together. Flat turns are obtained directly on the working attachment of the equipment or are made on semi-automatic machines. In the first case, the ends of the springs are not bent, and in the second case they are bent for connection.

The raw material is low carbon steel wire without anti-corrosion layer. They use products with zinc or polymer coating, produce stainless steel or aluminum wire.

They sell the net in rolls 1.5 m high, 10 m long. By individual order, they make material up to 4 m wide, and the roll length is increased to 18 m. The product labeling indicates the width of the cell, the thickness of the wire, the width and length of the roll. The rolls are rolled in the usual way or using the compact method when the roll diameter is significantly smaller at the standard length.

For example, a brand 60x60x2 (1.5x10) means:

- cell 60 x 60 mm;

- wire 2 mm;

- roll 1.5 m wide, 10 m long.

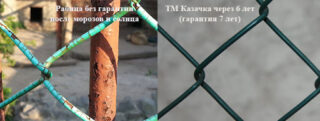

The hot-dip galvanized layer protects against corrosion, the mesh will not rust until 23-30 years. There is a zinc coating using an electrolytic method. Such a product is also called galvanized, but the layer is small, corrosion occurs in 8 - 10 years.

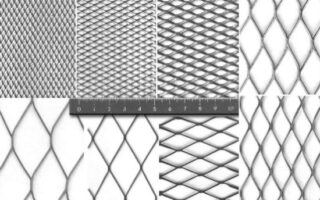

Varieties of material

The strength of the mesh depends on the size of the mesh and the thickness of the wire. Manufacturers can reduce the diameter of the spirals, increase the links, so the reliability of the material decreases.

According to the shape of the links, the following types are distinguished:

- diamond-shaped weaving;

- square types of knitting.

To check the correctness of manufacture, the roll is weighed and the mass of 1 square of the grid is compared with the standard. A difference of 5% or more indicates weakened cells.

According to the material of the outer layer, varieties are distinguished:

- galvanized mesh;

- non-galvanized products;

- polymer coated goods.

The thickness of the layer is measured in g / m², determined by laboratory weighing of the coated and uncoated sample. There are products on the market with a layer weight of 10 - 90 g / m². The working conditions of the mesh during operation can affect the evaporation rate of zinc and reduce the life.

Non-galvanized mesh is called a black chain-link and is used for temporary fencing of territories in a gentle environment. The service life is determined at 10 years. Polymer is placed in conditions of aggressive atmosphere, high humidity, for example, on the seashore, in industrial areas with acidic impurities in the air.

Mesh for self-construction fencing

A chain-link fence is made so that it lasts 25 - 30 years without loss of quality, for this material is chosen taking into account technical criteria:

- all links are even, without distortion;

- the ends of the spiral threads are bent towards their own base;

- spirals are intertwined with each other without gaps;

- the roll is tied in three sections, the ends are packed with paper, film;

- a label with information about the manufacturer and product labeling is attached to the product.

The cost of the material ranges from 89 to 275 rubles / m². Low-carbon wire is more ductile, while galvanized wire is stiffer.

Cell sizes:

- not galvanized is produced with threads 1.2 - 5.0 mm thick, cells 50 - 100 mm;

- in galvanized wire, 1.6 - 5.0 mm wire is used, the links are made 50 - 100 mm;

- with a plastic coating, wire rod with a diameter of 2.8 - 2.8 mm is taken, the cells are made 25 - 50 mm.

The polymer coating is applied to galvanized wire or filaments without any coating. The service life depends on this, so the seller must show a quality certificate for the product. The net roll weighs an average of 34.2 kg. The weakening of the mesh is indicated in the technical documentation, the difference in weight is allowed by 0.5 or 0.2 and 1 mm, depending on the size of the links.

Advantages and disadvantages of a chain-link fence

You can make a fence from a chain-link mesh at the lowest price compared to other fence options. The low weight of the material and pillars excludes the construction of a strong base for support.

Positive aspects of using a chain-link for a fence:

- resistance to wear, resistance to external factors, for example, water, temperature fluctuations, sunlight;

- strength in case of mechanical shock, burglary attempt, it is easier to break through a wooden fence than to break a steel net;

- permeability of the material for viewing the inner space of the courtyard and viewing the street from all sides;

- does not hold back the sun's rays, undersized bushes and vegetation feel comfortable near the fence;

- undemanding in care, repairs are rare, during restoration they change the damaged area;

- availability - sold in any hardware stores, stalls;

- a large assortment allows you to choose the weight, mesh size and wire thickness;

- quick installation - you can install the fence together with the digging in of the supports in a day together with an assistant.

The fence mesh has the disadvantage that it is not very nice looking. The material needs to be dyed to increase its attractiveness and extend its service life.

Preparatory stage of work

Before making a chain-link fence, prepare. They make a sketch of the location of the pillars, mark the gate, wicket. Calculate the volume of the mesh, the footage of the pipe for the supports, determine the mass of sand, cement, crushed stone for concreting in the ground. The sketch indicates the places of digging in the pillars, taking into account roads, sidewalks, relief features.

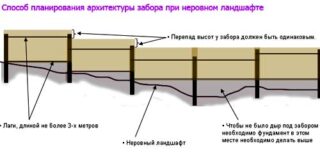

If a fence is being built on level ground, there are no difficulties with marking. A fence on a surface with a slope requires careful attention, since the supports will have to be dug in at different levels. In this case, the mesh is stretched so that its edge runs parallel to the conditional line of connection of the tops of the supports.

If the mesh is stretched without dividing into sections, the length of the fence and the distance between the supports can be taken arbitrarily. Sectional installation requires the delineation of areas at the design stage.

They clean the place where the fence passes, cut down the interfering bushes. If there are trees on the way, it is better not to destroy them, but to move the border of the fence. Metal, wooden racks are placed for the mesh. Reinforced concrete ready-made supports are used or concreted on site, brick columns are erected, asbestos-cement pipes are installed.

Material calculation

The number of the mesh is determined by the length of the fence in running meters. Divide the required amount by the length of one bundle and get the number of iron rolls. The fence can be placed on both sides of the supports, then the resulting footage of the fence is multiplied by two.

Very high fences are made with the installation of two or three layers of mesh in height, therefore, when calculating the amount of material, this circumstance is also taken into account.

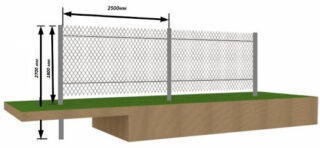

The number of pillars is determined so that the distance between them is about 2.5 m. At corners and turns, add a support, even if the distance is less than the specified one. This rule applies to tension and sectional installations. The distance is chosen so as to connect the netting on the pole, and not on the weight between the supports.

For the manufacture of sections, the number of the corner is considered, the length is taken according to the distance between the posts, and the height is calculated so that it is not necessary to cut the roll in width. The number of corner around the perimeter of one card is multiplied by the number of frames and the total length of the material is obtained.

To calculate the concrete, the volume of one pit is calculated. The depth is 50 - 80 cm, the width is 50 cm. The number of holes is multiplied by the volume of one and the total cubic capacity of the finished concrete mixture is obtained.

What you need to work

Bayonet shovels are used to dig holes under the posts. For dense soil, scrap is used, the roots in the ground are chopped with an ax. The land is thrown into a dump or carried away from the site by stretchers or buckets. The concrete mass is prepared in concrete mixers, small-volume devices are chosen, since a little mixture is needed.

Shovels are used for throwing into the drum. If the solution is prepared by hand, you will need a trough in which the ingredients are mixed using trowels and shovels. In the pits, concrete is spread with a trowel, and an electric vibrator is used to expel air bubbles.

For welding, you will need an apparatus with the required consumables (electrodes, welded wire). For the racks, a profile pipe of square or rectangular section with a size of 80 x 80 mm or 80 x 100 mm is prepared, the wall thickness is 5 mm. The mesh frame is made of a similar material measuring 40 x 40, wall thickness 4 mm. The mesh is connected with a wire for knitting, you will need a hook.

Self-assembly

This type of tension is relevant on flat terrain, and on a slope it is better to make a sectional fence from a chain-link in order to take into account the height differences.

The first to install the corner posts, which will be a reference point for the rest of the elements, then put the pillars at the break points of the fence, behind them are the ordinary supports. The mesh fabric is pulled without guides, then a strong wire is pulled along the top, which will not allow the filling to sag over time.

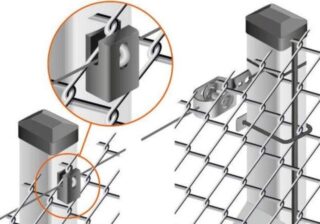

The material does not always retain its dimensions, the mesh is stretched, warped, so it is difficult to work with it. The roll is not unwound on the ground surface, but is immediately attached to the first rack. Hooks are welded on the racks, where the mesh is hung over the cells, the fixation is reinforced with wire.

It is advisable to work together to give the web a good tension. Gradually, the material is pulled from post to post and fastened with hooks. The guide wire is pulled and welded to the posts so that it does not sag.

DIY sectional fencing

Fence from cards requires more time to make strapping frames. The cost of this design is increased by the additional corner. Ready-made sections are sold on the market, but you can make them yourself.

The sequence of making a grid card:

- A rectangular frame is made from a steel corner, cutting is done with a grinder, then the segments are welded into the frame.

- The required size is separated from the roll by twisting one spiral from the canvas, and with the help of a wire (on four sides), it is pulled to the corners of the frame.

- The tension rod is welded to the corners of the frame, so the mesh is stretched.

There is an option when the frame elements are made with hooks on which the mesh links are hung. Then the pins (3 mm) are bent with pliers, the edges are fixed by welding so that the canvas does not slip. Sections to the support pillars are fixed by means of metal welded plates.

You need to pull the mesh together so that it does not warp and sag during installation.

Popular decorating methods

The grid allows you to view the courtyard, which is not always convenient for its inhabitants. A strong wind passes through the cells and carries dust and debris to the site, so the owners put decorative elements that decorate the fence, reducing permeability.

Types of decorations:

- vegetation in the form of a climbing hedge or vertical garden;

- profiled sheets, polycarbonate panels, slate;

- camouflage mesh;

- decorative weaving with colored wire, vine branches, hazel;

- artificial branches of flowers, conifers;

- reed or reed mats.

Openwork weaving is done with wire with a polymer layer. A simple ornament will decorate a chain-link fence. Vegetation is planted under a fence or mounted pots, pots with planted ornamental plants. They use climbing roses, thuja, conifers, plant hydrangeas, grapes. While the hedge is growing, landscaping with artificial elements is used.