Decking is one of the most popular materials used in the construction of fences. With its help, dachas, sports and playgrounds, as well as the territories of industrial sites, private houses, etc. are fenced. Among the operational characteristics of corrugated sheets, its strength, long service life and high quality of the outer surface are especially noted. The material is characterized by a low cost, which is of no small importance when fencing large areas.

Advantages of corrugated fences

The corrugated fence reliably protects the territory from the penetration of unauthorized persons. A fence made of this material has a number of advantages that are unusual for similar structures:

- installation without foundation;

- a wide range of standard polymer coatings;

- the possibility of original painting of the galvanized surface of the boards;

- simple installation of the fence and maintenance of it during operation;

- high wear resistance and durability of the assembled structures.

The polymer coating reliably protects the sheets of corrugated board from negative climatic influences.

The choice of corrugated board

When choosing sheets of corrugated board for a fence, you need to pay attention to the marking, which indicates the purpose of this type of material and its bearing capacity.

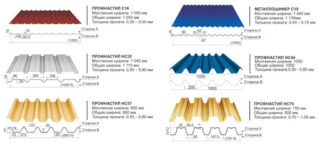

The industry produces corrugated board of three brands:

- H (bearing) - the most durable sheet designed for the arrangement of interfloor ceilings. Additional rigidity is given to it by special grooves in the middle of each wave.

- C (wall) - used for wall cladding and installation of fences. It is made of thin sheet steel. The waves formed on it have a small height and width.

- NS (bearing-wall) - is used as a roof covering and is considered a good alternative to metal tiles. Compared to sheets of grade "N", such a sheet has a lower rigidity.

For arranging fences, sheets of corrugated board grade C - C8-C44 are most often used. If necessary, you can use non-material-wall sheets HC35.

The number after the letter designation indicates the size of the wave height in mm, which generally determines the final stiffness of the sheet. C20 sheet has a wave height of 18 mm. When using sheets of grade HC, they should not have a capillary groove.

For corrugated fences, C8 sheets are used. In areas where fences are exposed to strong wind loads, it is better to take sheets with a wave height of 10 mm or more.

Taking into account that the fences of private houses also perform decorative functions, it is recommended to purchase painted corrugated board for them. In addition to the improved appearance, such sheets are more durable.

Arrangement of a fence made of profiled sheet without welding

Structurally, metal profile fences without welding consist of the following elements:

- support pillars that must be securely installed in drilled wells;

- crossbars (lag) connecting the pillars to each other;

- professional sheets attached to the lags.

Required materials and tools

The installation of the profiled sheet is preceded by work on the installation of support pillars and the assembly of the frame of the future fencing.In addition to metal pipes of round or square cross-section, you will need special fastening elements for a fence made of corrugated board without welding:

- Square metal cross-beams.

- Brackets with holes for fixing corrugated sheets.

- End caps (if required).

- Fence fasteners without welding (screws or bolts M6 with a length of at least 20 mm, self-tapping screws or rivets).

- U-shaped decorative strips installed on the upper end of the sheets.

To simplify the work, use ready-made support poles, equipped with a "heel" (support on a sand cushion) and a top plug, as well as holes for fixing the crossbars.

When installing a fence from a profiled sheet with your own hands without welding, you need to prepare the following tool:

- manual garden drill or motor drill;

- shovel;

- container for preparing concrete;

- plumb line;

- building level;

- screwdriver;

- grinder.

For concreting pillars or pouring a foundation, you need to stock up on cement, sand and gravel. The presence of a primer, anticorrosive composition and paint for corrugated board will also not hurt - with their help, they mask defects that appeared during the installation of sheets, and paint over the sections of the sheets (if necessary).

Installation of supports

Fencing made of corrugated board belongs to the category of light structures that do not need a strong foundation. The following are considered optimal for them:

- shallow foundation, 30-40 cm deep;

- concreting of supports, the well for which must have a depth of at least 1/3 of the height of the support pillars + 10-15 cm on a gravel-sand pad.

The supports are positioned according to a previously drawn up scheme, and first the base pillars are installed and only then the intermediate ones. You can add strength to the supports by reinforcing the foundation or free-standing supports. A structure of connected steel rods is laid in the foundation, and a glass of steel mesh is placed in separately dug holes, covering the support.

Fixing the crossbars

After the concrete has hardened (this will take at least 5 days), they begin to assemble the frame of the fence. For the collapsible connection of its elements, brackets with holes are used, which must be screwed to the supports. If ready-made supports equipped with special brackets with holes for attaching the crossbars were used, the latter are screwed to them. In this case, there is no need for separately prepared holders.

They attach the logs to the fence posts without welding in various ways:

- on the front side - end-to-end, which is ideal for solid fences;

- behind - in cases where a sectional fence is designed;

- on the side - the sheet of the profiled sheet is attached not only to the logs, but also to the support pillar itself, in this case the consumption of self-tapping screws will increase, but the connection itself will be more reliable.

Installation of a profiled sheet on a frame

Profiled sheets are attached to the frame lags with special screws or rivets. It is important to set the first sheet correctly. For this:

- Determine the position of the upper edge of the sheet and fix it with one self-tapping screw.

- Using the level, set the second edge to the desired position and also fix it with a self-tapping screw.

- The rest of the screws are screwed in, and one mount should be in the center, and the rest - every two waves. The sheet is fastened through the lower waves.

- All other sheets are mounted in the same way with an overlap on the last covering wave of the previous sheet. The sheets are connected to each other through the upper wave.

To maintain the integrity of the gaskets, the self-tapping screws must not be fully tightened.

The assembly of the fence from corrugated board is completed without welding by installing plugs on the ends of the support posts and decorative strips on the upper cuts of all sheets. The latter are fastened with rivets matched to the color of the sheets.