The bolt is a locking mechanism that keeps the gate in a closed position. The presence of a high-quality shutter facilitates the operation of the doors and resists burglary. Stores offer a wide assortment line of valves made of different materials. However, having read the instructions for making a bolt on the gate with your own hands, you can create a high-quality shutter.

Types of bolts and latches for gates

Most types of locking mechanisms can be purchased at a hardware store or construction center. But often summer residents and owners of country houses prefer to independently make bolts for the gates.

For production, materials that are always at hand are suitable - wood, metal profile, rod, etc. The raw material for the retainer is selected similarly to the gate or from combined options. The production technology is also different.

Varieties of locks on the gate with your own hands:

- Rotary structures include a spinner and a barrier. No specific knowledge is required for manufacturing. The devices are reliable and play the role of "anti-vandal". Wood is used as a material. Cons - heavy weight and outdated design. Although in some cases, such a flap will complement the authenticity of the exterior.

- Sliding horizontal locks - strip and latch bolts. They are mounted on the sash, fixing one to the other or to the frame. Can be completed with a vertical design. Such mechanisms are not suitable for all entrances. For example, you can make such a bolt for swing gates with your own hands.

- The purpose of the vertical sliders is to hold the canvases individually and fully open. Installed on the bottom or top of the frame.

Vertical devices are expensive items, especially for side doors. In most cases, a pinwheel or latch is used due to its low financial costs.

After studying the varieties of locking mechanisms, you can make such a device yourself.

A simple option is a gate valve or gate valve made of a rod and pipe. The inner diameter of the product is selected slightly wider than the moving part, but the rod should not dangle in it.

Self-manufacturing technology for gate suction

The design of the retainer depends on many factors - the size and material of the gate, the budget, the availability of welding and carpentry skills. To choose the best option, familiarize yourself with each type of bolt and its manufacturing technology.

Before creating a custom valve, prepare a tool - a hacksaw, a hammer, a drill, a welding machine, and a screwdriver. Auxiliary materials - tape measure, pencil and vise.

Sliding gate bolt

The sliding mechanism is equally used for wickets, doors and gates. For manufacturing, you need a metal plate 5 cm wide and 40 cm long. The prepared device will move forward / backward in a special groove.

Step-by-step instruction:

- mark the places of future fastenings at a convenient height;

- install the grooves or rings on the bolts or weld;

- insert the plate;

- to increase reliability, use additional vertical clamps.

For the garage door, you will need L-shaped rods, ѳ10 mm. A stop is mounted in the upper part of the sash so that it can be fixed in the closed position. For swing gates, two rods are made with mounting at the bottom.

To install the gate valve on the corrugated board gate with your own hands, you need to fix the pins in the recess. It is recommended to use a garden drill to maintain the correct diameter. The disadvantage of the constipation is low fixation - in case of gusts of wind, the sashes from the profile metal are twisted. Installation of three valves at a distance of half a meter in the upper, lower and central parts will strengthen the gate structure.

How to make a spinning bolt

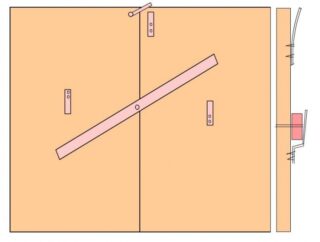

Pinwheel - made from a rectangular strip or shaped pipe, a through bolt acts as an axis. The latest lock for entrance and garage doors. Often, the mechanism is used in sheds, utility blocks and barns - in places where an entrance / exit swing structure is used. Such mechanisms are not produced by factories, but it is easy to make it yourself.

DIY gate bolt manufacturing technology:

- Prepare a timber beam or a thin channel. It is recommended to measure ~ 2/3 of the sash width - often 1 meter is enough. The thickness of the timber is at least 5 mm, the thickness of the steel strip is 5-55 mm.

- On one of the flaps, make an indent from the edge 60-100 mm and make a hole for an M10 or M12 bolt. Choose fasteners with a wide head. The length is equal to the sum of the thickness of the gate, the locking mechanism, 2 washers and nuts. The head must have sharpened edges. To avoid detection from the outside, paint in the color of the gate.

- Drill a wooden beam or a U-shaped profile in the center and put it on the bolt. Secure with locknuts.

- Fix the fixed channels on both sashes - the lock will enter into them when turning. To easily open the gate, as well as to strengthen the sashes, make slits in the form of a wedge.

Such a locking mechanism is distinguished by its strength and clamping ability. It is used in summer cottages, cottages and garages.

Choose a bar made of wood for a bolt with a thickness of 50 mm or more.

Bolt in the form of a latch

To make a latch bolt, pick up a rod with a diameter of 10 mm or more and attach the handle - the result will be a T-shape. A reliable way of fixing is welding. In the absence of equipment and experience, drill a hole in the bar, cut the thread and tighten the bolt. Pick up a metal pipe with such a diameter that the rod moves in it easily and does not play.

The technology of creating a bolt-latch on the gate:

- Cut a piece of ~ 100 mm and two pieces of ~ 50 mm from the pipe.

- Weld the long part to one flap, and the short to the second.

- Install the rod into the pipe until it stops, put the remaining piece on the free end and fix it with welding. Check that the gate opens and closes without interference.

- To lock in the closed position, weld the metal plate to secure the handle in this state. Additionally, you can install a loop for the lock to increase the reliability of the shutter.

Locks in the form of a turntable, a barrier and a latch are equipped with padlocks. This allows for increased protection against burglary.

Production principles of vertical bolt for swing gates

The purpose of the vertical bolts is to fix the lower part of the wicket or door leaf, as well as to keep the leaves open. For manufacturing, an iron rod ѳ from 1 cm, L-shaped corners and a tube are used.

Do-it-yourself lock for swing gates can be done according to the following instructions:

- Weld the tube to the bottom of the gate.

- Insert a pin into it and make a hole in the concrete base or frame.

- To fix the bolt in the open state, weld the stop to the sash.

Vertical locks are also installed in the upper part to strengthen the door leaves and give them stiffening edges. But for them it is necessary to equip additional fasteners so that the retainer does not fall out when the gate is opened.

Arrangement of latches and latches on sliding gates

For a sliding type of gate, use a bolt "latch" or "latch". These types are combined with different locks and bolts. Latches prevent the doors from opening from the outside. To manufacture the structure, you will need old or unnecessary parts from a Russian-made car. In the absence of spare parts, the use of any available items is allowed.

To create constipation on sliding gates, follow the order:

- At the corners, make one hole for each part and fix the elements on the gate leaves.

- Place the fasteners in one line, and parallel to them, make indentations in the concrete or ground.

- Take a curved tube ⅔ of the width of the gate and position it so that it runs over the corners. In this case, the bend must penetrate into the base (earth / concrete). The lock will keep the gate closed.

- Use a pipe for the vertical bolt. Mount a kind of lever on the frame. Then attach another tube of smaller diameter to it.

The miniature element is able to keep the doors open even in strong winds. Two iron pipes with additional reinforcement will become a reliable lock for the gate.

Sly bolt

There is another type of locking mechanisms - a bolt with a beam and a latch. The secret of the latch is that it imitates a working lock. To make a false panel on the inner side of the door, weld segments of a rectangular pipe with a section of 0.15 m - they act as guides. On one side, weld the butt so that the constipation does not fall out. In this case, the length of the bolt is 1.2-1.8 meters. Outside, fix the retainer with 4 bolts, but only one of them holds the bolt, the others are needed for "trick".

A fake well is also used as a disguise, behind which a part of the lock is installed. When the key is inserted into it, the impression of turning is created, but in fact nothing happens. The owner will need a candle key to open it.