Ventilation under the stove in a bath is one of the most difficult stages of construction. On the one hand, it is necessary to maintain a high temperature here, on the other, to ensure the safety of those who are steaming and to prevent the accumulation of moisture in the room.

Ventilation system in saunas in steam rooms

The extractor hood in the steam room in the bath has 2 main functions: it provides fresh air and drying the rooms at the end of the bath procedures. In this case, ventilation is considered effective if 3 conditions are met:

- does not violate the set temperature due to excessive intake of cold air;

- does not stratify the air into cold and warm streams;

- does not remove fresh air, thereby leading to the appearance of mold and mildew.

The ventilation capacity determines the type of steam room. In a Finnish sauna with low humidity, the risk of fungal growth is minimal.

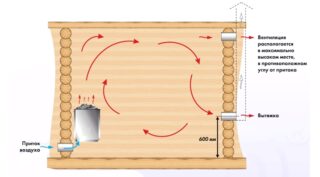

The design of ventilation in a bath from a bar or log is based on the following principles.

- Openings for fresh air supply are placed at the very bottom of the room. If possible, the inflow is installed next to the stove so that the incoming air warms up as quickly as possible.

- Exhaust holes are made under the ceiling on the opposite wall to obtain natural draft. It is not uncommon for several exhaust openings to be placed at different levels. In this way, the direction and strength of the air flow can be controlled by closing and opening the plugs.

- The thrust is determined by the position of the exhaust port. The greater the difference in height between inlet and outlet, the better the draft. The minimum difference is 1 m.

The air in the steam room is renewed every 2-3 hours.

Exhaust openings should also be installed in the washing room, in addition to windows. It is important here to quickly remove excess moisture.

Types of ventilation systems

There are 3 types of hoods in a brick or wooden bath.

- Natural - the intensity of air exchange in this case depends on the difference in temperature outside and inside the steam room. Since it is very high in the steam room, there will be good cravings even in hot summer. In an unsuccessful position, cold air accumulates near the floor, and steam rises to the ceiling.

- Forced - the air flow is created by a deflector or an axial fan. Install devices in the exhaust duct - near the hole or closer to the middle. The plus of this option is independence from weather conditions, the minus is that it consumes energy. In addition, you need to select devices that are protected from moisture and temperature in the steam room.

- Combined - in this case, the supply and exhaust are arranged so that in a favorable season it works according to a natural mechanism. If its power drops or becomes insufficient, for example, in rainy weather, turn on the fan mounted in the hood. This option is more economical.

It is not difficult to convert natural ventilation with combined ventilation.

The material of the building and the construction of the walls influence the choice of ventilation.

- A log house or a building made of timber is equipped with a natural draft. The tree has the ability to remove some of the moisture, which makes it easier to ventilate.

- A frame building assumes a high degree of insulation and sealing. Here, a fan is required to ensure normal air flow.

- In buildings made of bricks, cinder blocks, foam concrete, gas silicate, aerated concrete, artificial ventilation is installed.

The hood is planned at the stage of project creation. Correcting something afterwards is much more difficult.

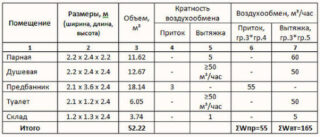

Calculation of ventilation in the bath and steam room

Do-it-yourself hood in the steam room of a bathhouse, even the simplest one, requires careful calculations. It is recommended to contact the experts and create a plan based on their recommendations.

The hood in the steam room or washing room is part of the ventilation system of the bath. In this case, it is necessary to take into account not only the power of the air flow, but also its direction, which is more complicated.

Key points:

- Air flows in and out in the same volume. They regulate the flow with dampers: for heating, the dampers are completely closed, for ventilation, they are opened.

- Fresh air should freely flow through the washing room into the dressing room, bathroom and vestibule. The guest room has its own ventilation duct.

- Moist heated air from the recreation area freely comes out through the washing room or bathroom.

- If a gas water heater is installed in the bath, special channels are made for it.

- If the air circulates forcibly, it is necessary to install a ventilation grill.

It is advised to equip the Russian bath with a forced draft hood in order to dry the room as quickly as possible.

Basics of calculating the hood

Estimates are based on the volume of the room and the number of openings required for ventilation.

- The air in the steam room should be completely renewed in 2-4 hours - in a room with a cubic capacity of 6.3 m³ per hour must pass from 1.6 m³ to 3.2 m³.

- In small rooms, 1 hole for supply and exhaust is sufficient. Calculate their area using the formulas. For every cubic meter of sauna room there is a ventilation opening of 24 cm².

- It is recommended to use the calculated value for the inflow hole, and make the exhaust holes even larger.

- The area of the ventilation openings should be as large as possible. It is easy to reduce them by installing plugs. But if the opening is insufficient, the hood will be too weak.

If the room is spacious and there are several holes, the calculations are more difficult.

If the holes are too small, carbon dioxide and moisture will accumulate in the steam room, which will lead to rapid wear of the material and damage those who are steaming.

Components for the construction of ventilation

To make ventilation in the steam room or in the washing section of the bath, you will need:

- wood or tin for ventilation ducts;

- gratings and valves or material therefor;

- tow, jute - for sealing cracks;

- a fan made of special plastic, resistant to high humidity and temperature extremes;

- blowers;

- ventilation valves;

- adhesive tape and sealant, polyurethane foam, pipe clamps;

- fasteners.

It is recommended that mosquito nets be placed over the ventilation openings to keep out insects and debris.

Ventilation in the bath with your own hands

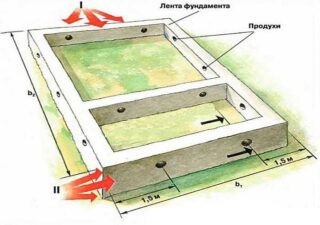

The organization of the ventilation system begins from the stage of building the foundation. The step-by-step guide includes the following steps:

- When laying the foundation at the level of the basement of the building, they make airflows in the bath. The diameter of the hole is usually 12 cm, but in general it does not depend on the volume of the building, but on the remoteness of water bodies and other buildings.

- The holes in the strip foundation are made opposite each other. If there are many natural barriers to the passage of air around the building, holes are made from all sides.

- There is not enough air in the foundation to dry floors in a washing or steam room. Equip a ventilated floor. Water and settled steam pass through the floorboards and are collected in a ventilation pipe. The latter is equipped with a deflector. The pipe is taken out to the roof. Installation in the attic is allowed, but this option turns out to be ineffective during the rainy season.

- If the water from the steam room goes directly into the ground or the drainage layer, the ventilation duct is not installed.

- In the dressing room, humidity and temperature are kept at an average level. For ventilation, it is enough to arrange a ventilation window, put a grill and a valve. Also, the role of the hood is played by the door to the outside, through which it is easy to let fresh air in.

- In a washing room with a window, the vent plays the role of a missing ventilation element. If there are no windows, an outlet is made in the washing bath, as in the steam room. If necessary, install a fan here.

- If the bath complex has an attic, it is also equipped with vents. At the stage of installing the rafter system, supply openings are installed under the roof canopy, and exhaust openings on the gables and ridge. The area of the holes is at least 1/500 of the area of the attic.

If you forgot to make air vents in the bath, even artificial powerful ventilation will not always cope with its task. In addition, the ventilation holes, which create natural air exchange, allow you to install less powerful appliances and not turn them on all the time.

Additional Tips

To ensure normal air circulation in the bath, adhere to the following recommendations.

- In no case should you plug it with a rag or fill it with foam for the winter. In this case, the ability to remove steam disappears completely and moisture accumulates inside the bath. The air must be left open.

- To create air vents in the foundation, it is better to use asbestos-cement or plastic pipes, rather than wooden blocks. Piping out is much easier.

- Ventilation openings located low above the ground are covered with strong grates to prevent rodents from entering the bath.

- It is better to install air vents in the room after decorative finishing.

The arrangement of ventilation in the bath guarantees an optimal microclimate and a long service life of the building. Insufficient ventilation is the reason for the accumulation of moisture, rotting wood, the appearance of mold, the destruction of finishing materials.