For a garage to last for a long time, the roof must protect it from rain and snow, withstand the wind, resist corrosion and maintain an attractive appearance. Different materials are used for this - ondulin, bituminous tiles, slate, but the most popular is the profiled sheet.

Types of garage roofs

Roofing materials are chosen taking into account the roof structure and the slope angle. There are the following options.

- Flat - this is the name of a single-slope model with a minimum inclination angle of 3 degrees. It cannot be made completely flat, otherwise water and snow remain on the roof and exert excessive stress. Suitable only for small buildings.

- Single-slope - with an angle of inclination from 6 to 60 degrees. To install it, a rafter system is required. Roofing material is chosen depending on the angle of inclination.

- The gable roof of a garage made of corrugated board is most often done by hand. Its installation takes more time, since a frame needs to be erected for it. The angle of inclination of the slopes is determined by weather conditions.

More complex structures in garages are extremely rare. Usually in cases where it acts as part of a complex residential building.

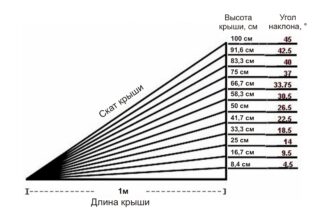

Tilt angle

A steep slope - more than 60 degrees, does not hold up snow and rain. However, it has a large wind capacity and is unprofitable in the regions with strong winds.

The angle of inclination affects the choice of roofing material. For flat, they are mainly used in rolls, like roofing material or asbestos-cement sheets. At a value of 6 degrees, they are covered with bituminous tiles. The permissible roof angle for ceramic is 11.5, and galvanized iron can only be laid on the slope at an angle of 14 degrees.

The minimum permissible slope angle for a profiled sheet is 12 degrees.

Advantages and disadvantages of corrugated board

If you cover the roof of the garage with corrugated board with your own hands, you can count on the following advantages:

- the profiled sheet is covered with a layer of zinc, so that it does not corrode;

- sheet weight is minimal, which facilitates installation;

- low price;

- galvanized metal profile does not need maintenance;

- simple repair;

- the material is attractive and does not fade in the sun.

Minuses:

- metal conducts sound perfectly, such a roof is very "loud";

- if the protective zinc layer and paint are damaged, the metal begins to rust.

The warranty period for corrugated board reaches 25 years.

Selection guidelines are very simple:

- only galvanized steel with a polymer coating is allowed;

- sheet thickness not less than 0.45 mm;

- trapezoidal profile, preferably with a stiffener;

- the type of profile is chosen according to the angle of inclination of the roof.

The quality profile must be marked and indicated by the country of origin.

Design features of a corrugated roof

Profiled sheet is used to cover the roof of wooden, frame, block buildings. With a sufficiently steep slope, an attic space is built, used as a warehouse for tools, building materials.

It is easier to build a single-slope structure, since the area of the box is usually small.If the garage is designed for 2 cars, a gable one is installed. Be sure to make a drawing of the roof: it is easier to calculate the amount of material this way.

Preparatory work

The following tools are needed to cover the roof:

- a hacksaw for metal or electric scissors;

- screwdriver, hammer;

- screwdriver;

- tape measure and building level;

- self-tapping screws with rubber washers;

- professional sheet in the required volume.

For the construction of the roof, you will also need a wooden beam for rafters, waterproofing, and sometimes insulation.

Cutting corrugated board

The material is classified as thin-sheet. In addition, it is covered with a protective zinc layer. Therefore, ordinary tools, like a grinder with an abrasive wheel, are not suitable. To properly and cleanly cut the sheets, use:

- hacksaw - does not leave burrs, but not suitable for curved cuts;

- jigsaw - allows you to cut along and across the sheet;

- scissors - the cut is made in any direction, but has rough, sharp edges.

To cover corners, cornices, skates, sheets are not cut, but bent.

The process of laying corrugated board

- Work begins with waterproofing the rafter system. Roll material is used, which is laid on the rafters without tension. The joints are sealed with tape.

- If the garage is insulated, heat insulators are placed between the rafter legs in the resulting cavities. They use mineral and basalt wool - it is cheap and retains heat well.

- Under the corrugated board, you need to make a crate. What it should be - solid or lattice - depends on the angle of inclination.

- Cut the corrugated board to size.

- Lay the sheets starting from the bottom edge. Align with the eaves and make an overhang. Each next sheet covers the previous one with an overlap so that their profiles coincide.

- If the angle of inclination is less than 15 degrees, the joints of the sheets are sealed with a sealant.

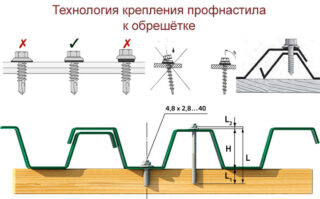

- The coating is fastened with self-tapping screws through the lower wave. The step is 50–70 cm. The fasteners are not rigid, preferably with rubber washers.

- After laying the sheets, additional elements are mounted, like gutters, drips, skates.

When working with corrugated board, observe safety precautions: wear protective gloves, an apron. They move along the roof on toes in soft shoes.