The Russian bath is a standard building with straight walls and a pitched roof. In summer cottages, this is most often installed. However, there are other options, for example, a barrel bath with your own hands.

Design features

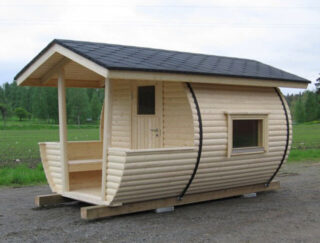

This option primarily attracts with its unusual design. In appearance, the structure resembles a barrel lying on its side. Sometimes it has a roof, but more often the structure does without it: the slope of the surface does not allow water and snow to accumulate here.

The second feature is size. The standard barrel height is 2.2 m, which allows even a tall person to move freely. The length may not exceed 2 m. Such a steam room will have to be used one at a time, but it also takes up a minimum of space on the site.

The design can be even larger: with a diameter of 2.5–3 m, it can reach 6 m in length. In this case, it is a full-fledged sauna complex with a steam room, a washing room and a changing room.

The sauna is heated in the usual way. You can put an electric heater, you can use a wood-burning stove, if there is a sink, choose a model with a hot water tank.

There are mini-saunas at home. They are arranged in an ordinary large barrel, up to 180 cm high. The head of the seated person often rises above the wall of the bath. In this case, the stove is replaced by a steam generator.

Advantages and disadvantages of barrel saunas

In addition to its interesting shape, a cylindrical sauna building has a number of practical advantages:

- The cylindrical configuration minimizes heat loss. To completely warm up the room, 8–9 logs are enough.

- The barrel bath heats up to the maximum set temperature in 30 minutes. No rectangular design can compete with it.

- The construction is very light and does not require a foundation. It can be placed on a concrete or asphalt surface.

- If the building is insulated, you can bathe in it all year round.

- The construction of a rounded building will cost less than an option with the same internal volume, but a standard shape.

The disadvantage of the design is its small internal volume. The steam room here is designed for 2 people, no more. It will be difficult for three of them to miss each other in a tight space.

Where is the best place to install

There is only 1 requirement for the location of the barrel-bath: the site must be perfectly flat. The foundation is not required, although it is preferable to place the complex on piles on the slopes or in the lowlands.

The structure is not capital, as it does not have massive walls and foundations. This means that the SNiP norms do not apply to the barrel bath, it can be installed anywhere, taking into account only the fire safety rules - not less than 8 m from a residential building.

Preparation of material and tools

To make a bath-barrel for a summer residence with your own hands, you will need the following:

- boards - 5 cm thick, 9 cm wide, the length depends on the length of the building;

- iron hoops - they fasten the structure;

- sand, gravel and liquid concrete for the site;

- door and window structures;

- pipes - plumbing and chimney;

- oven - electric, wood-burning;

- fasteners - nails, screws, bolts;

- insulating materials - insulation, waterproofing, soft roof tiles, etc.

Of the tools you need:

- ax, saw, shovel, plane and hammer;

- jigsaw, drill and screwdriver;

- building level, plumb line and tape measure.

You will also need materials for decoration, antiseptics for impregnating wood.

Choice of materials

Only hardwoods are chosen for construction. Pine and spruce wood contains too much resin. As the temperature rises, the resin is released and contaminates the surface. The board gets too hot and absorbs dirt.

Most suitable:

- Oak is the strongest and most beautiful tree, insensitive to water and steam, and extremely durable. The downside is the high cost, such a budget bath cannot be called.

- Larch - inferior to oak in beauty and strength, but also insensitive to moisture. Larch only becomes harder from water.

- Linden - perfectly tolerates the action of water and steam, does not heat up, is resistant to mold.

- Aspen - almost does not shrink, its properties are similar to linden.

Aspen is prone to rotting during growth. When choosing a material for a bath, you need to very carefully select the boards. High-quality material does not rot afterwards.

The exception among conifers is cedar. The wood is very beautiful, has high disinfecting properties, but heats up a little more than linden.

Bath layout options

The barrel bath is small from the inside - this is one of its advantages. The layout of such a small structure depends entirely on its size.

- If the length of the building does not exceed 2 m, it includes only the steam room. The washing room and changing room will be equipped under a canopy. This is a summer option. Such a bath is placed next to a summer shower, a swimming pool, a wooden plunge pool.

- The 3 m long barrel provides a 2 m² changing room.

- In a 4-meter building, the layout remains the same, but the area of the steam room and changing room is increased. Here you can place benches up to 2 m long.

- With a maximum size of 6 m, a washing room is equipped in the bath, and the dressing room is combined with a guest room.

Although a large complex includes all the necessary premises, no more than 2-3 people can freely accommodate here.

Preparatory work

The drawing does not depend on the dimensions of the structure. The bending radius is the same for any size, only the length of the structure is different. The simplest diagram includes an image from the end, where the inner and outer radius and parameters of the doorway are indicated.

The second projection shows the barrel in section. The plan indicates the location of the partitions, if a washing and dressing room is planned, the location of the stove, chimney and water pipes. They also indicate internal doorways.

It is recommended to provide a list of materials with parameters in the diagram. This makes it easier to calculate the required amount of materials for construction yourself.

Construction stages

Although the foundation for the barrel bath is not needed, it is necessary to equip a flat area for it, therefore, construction begins with earthworks.

- Dig a trench of the required size and a depth of no more than 20 cm.

- Pits are being dug next to the trench to drain the water. Even if the soaked one will be placed under a canopy, a pit will be needed. A pipe is immediately installed, which will later divert water to the reservoir.

- A mixture of sand and crushed stone of medium and fine fractions is tamped at the bottom of the pit. Steel wire reinforcement is laid and poured with liquid concrete. Make sure that the resulting area has a slope of 3 mm per 1 meter for rainwater to drain.

- Coasters are made. A recess is cut out of the board with a radius equal to the radius of the barrel curvature. You will need 2-4 stands.

- After 3 weeks, when the concrete has set, the supports are installed and fixed on the anchors. The position is checked with a plumb line.

- Collect wooden shields.If the bath includes only the steam room, then 2 boards are needed, if the dressing room - 3, if the washing room - 4. A window opening is cut through one of the boards, and doors are cut in all the others. The dimensions of the openings are minimal - the width is no more than 80 cm.

- The center of the shield is found, a radius is laid out from it and a circle is drawn according to the size of the future barrel. Saw out the blanks with a jigsaw.

- Cut out door and window openings. Temporarily reinforce the openings with bevels.

- Take boards equal to the length of the bath. Mark the grooves on them, into which the front and rear walls will be installed. If the bath has partitions, grooves are also made for them.

- They find the central zone on the supports and lay the board in the middle of the support. The rest of the elements are placed alternately, tightly joining with the previous board and fastening together. The base must completely cover the props.

- Instead of the last boards, corrective strips are installed at the edges of the support. They are wedge-shaped and help to compensate for gaps.

- Round wall blanks are installed in the grooves, give them a vertical position and fasten with self-tapping screws and bolts.

- From the boards, the round walls of the barrel are alternately laid out, fixing them on the back and front walls, as well as on the partitions.

- The assembly is completed by tightening with metal clamps at least in 3 places.

To reduce the load on the wood, the top of the barrel is covered with flexible shingles.

Finishing and auxiliary works

Step by step technology:

- In the place where the drainage pipe was brought in, a hole is cut in the floor, a drain is installed and connected to the pipe.

- For such a design, the most compact furnaces are chosen, usually made of steel or cast iron. The furnace body can be embedded in a brick or wooden box. The chimney from a steel pipe is led out to the conditional roof of the building. The walls and floor around the stove are sealed with thermal protection - asbestos or minerite sheet.

- On the floor of the steam room and the washing room, if there is one, a wooden grate is laid with gaps of 1 cm.

- Shelves are nailed to the walls in the steam room and dressing room. If there is space in the dressing room, you can install a table.

- They are installing windows and doors. Only wooden structures are placed here.

- Carry out electrical wiring. Cables are fixed directly on the wall; it is forbidden to hide them in PVC pipes.

- Water supply is organized to the washing room. Plumbing is laid underground and the pipe is introduced into the room as high as possible. The piping to the heating tank and to the washing room is done according to the conditional ceiling.

- The window usually copes with the role of ventilation of the barrel.

Both internal and external baths do not need finishing.

The barrel bath does not need insulation and protection from water and steam. The tree removes excess moisture and provides a stable microclimate. An ordinary stove heats up a bath in 30-40 minutes. If the fire is extinguished immediately after that, the set temperature is kept in the room for 2.5 hours.

Recommendations for the operation of the building

The design is quite unpretentious. In order for it to serve for a long time, it is worth following certain rules.

- After each procedure, the bath must be ventilated for 4–5 hours.

- Only dry non-coniferous wood is used for heating. The oven door must always be closed.

- The chimney is cleaned at least once every 3 months. Periodically, it needs to be cranked to burn out.

- The tree should be examined and treated with an antiseptic.

- The tension of the hoops is adjusted immediately after construction. The hoop should move relatively freely to compensate for the expansion of the wood during use of the bath.

- If a heating tank is used, it can only be switched on when it is at least 2/3 full of water.

- In winter, after the end of the procedures, the bath continues to be heated for several more hours with the internal doors open to get rid of excess moisture. Then the room is ventilated.

- It is strictly forbidden to use flammable liquids, such as gasoline or kerosene, for kindling, or to sprinkle unextinguished coals and ash near the bath. A wooden building is fire hazardous.

- It is not allowed to dry things near the oven in the steam room.

- It is better to equip a wood burning box outside the building, and not inside.

The barrel bath is an economical and compact option. It's easy to build it yourself, the rules for leaving are simple. The only negative: there is not enough space for a large company.