A wooden pool with their own hands is rarely built. With all its many advantages, the tree is prone to decay, does not tolerate high humidity, and even more so direct contact with water. However, this design is very attractive.

Pros and cons of timber frame pools

A wooden pool means 2 types of structures.

- Stationary concrete. The bowl of the reservoir is made of concrete in the usual way. However, the outside is finished with wood. This option combines the strength and durability of concrete, but it looks much more attractive. The project cost is high.

- Wood. Entirely made of timber. The reservoir is guaranteed for 15 years. The wood is treated with linseed oil or other water-repellent agents. The bowl is waterproofed, since the wood does not hold water well enough.

A frame pool made of timber has many advantages.

- Ease of assembly. It is enough to follow the step-by-step instructions to assemble the product yourself. For the winter, the wooden reservoir can be dismantled and reassembled in another place.

- It weighs a little. For a pool made of wood, you do not need to concrete the pit

- The cost of a frame is much less than a concrete one. It is more expensive than the inflatable model, but much cheaper than the steel or composite version.

- The bar model is easy to repair. Any part can be replaced with a new one at any time.

- Treated wood is well tolerated by water, rain and sun. In addition, the mechanical resistance of the timber is much higher than that of plastic or composite.

- Attractiveness - the material is beautiful, the colors and texture of the wood are very diverse. A pool with wooden sides always looks elegant and rich.

There are also disadvantages.

- The maximum service life is 15 years. If the rules for care are not followed, it quickly becomes unusable.

- It is not possible to install additional equipment, such as means for heating, cooling, foaming.

- You cannot leave the structure outside for the winter. The reservoir will not withstand such temperature changes.

- The configuration and size of the models are limited. It is almost impossible to give the bowl a rounded shape.

Due to the small size of the wooden reservoir, it is easier to care for it. There is no need to purify water, it is simply drained. The bowl does not need to be disinfected.

Choosing a location

Since the frame pool made of timber and planks is not installed on the foundation, it does not apply to objects whose position is regulated by SNiP norms. The location is determined based on other considerations.

- The area under the pond must be completely flat and without a slope. Better to choose an elevated site.

- The pool is placed in the sun. If necessary, you can stretch the shading mesh over part of the recreation area.

- It is undesirable to mount the structure next to tall trees and bushes. Leaves, flowers, debris in the water quickly clog up the pool.

An artificial reservoir should not interfere with the movement of people and cars in the country. If the family has children, it is better to place it so that it is in sight from the windows of the house.

Tools and materials

To build a pool from a bar or planks with your own hands, you will need:

- wooden beam with a section of 6 * 6 or 5 * 5 cm from rocks resistant to water;

- boards 2.5 cm thick;

- waterproofing film - usually polyethylene, 2-3 cm thick;

- water drain pipe, plastic water pipes;

- crushed stone, sand, concrete;

- drying oil, wax, varnish for coating;

- screwdriver, saw, drill;

- liquid rubber for sealing joints;

- tape measure, level, pegs and cord;

- fasteners - screws, nails.

An artificial reservoir can be equipped with a pump, skimmer, aerator, filters.

Calculation of the required materials

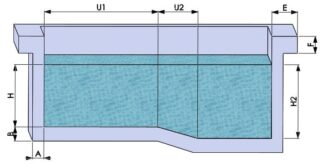

The calculation of the required amount of materials for a pool with a wooden frame is easy to do, especially for a rectangular reservoir. Step-by-step calculations are simple if you do them according to the drawing.

- The frame is a rectangular box without a bottom. In small sizes, it includes 4 main vertical posts and intermediate ones. The distance between them is 1–1.4 m, according to this ratio, the amount is calculated. The corners and intermediate posts are reinforced with spacers, so they are also taken into account.

- The number of boards is determined by calculating the area of each pool wall and summing them up. After that, the total value is divided by the area of the board. Take with a margin of 15%.

- Film dimensions are defined as the volume of the entire bowl with a 20% margin. The film must extend beyond the edges.

If a ladder is made, the number of boards required for it is taken into account.

How to make a frame for a pool with your own hands from wood

The construction of a pool made of wood and timber with your own hands is performed according to the following step-by-step instructions.

- Level the area under the reservoir, tamp the soil. If they want to bury the pool bowl in the ground, first they dig a pit of the required size, fill the bottom with a layer of rubble and sand and fill it with concrete. It is more expensive.

- Mark out the site. At the corners of the perimeter, holes are made for racks to a depth of at least 50 cm.

- The ends of the posts, which are immersed in the ground, are treated with bitumen or resin. They are immersed in pits and covered with rubble.

- Corner posts are aligned, connected with a cord. The rest of the racks are installed and fixed along the cord.

- In a predetermined place, pipes inlet and outlet are dug in.

- Boards for the sides are treated with antiseptics and drying oil. They are fixed on the racks horizontally, with a flooring, but not close, with a gap of up to 1 cm. Instead of boards, you can take waterproof plywood.

- Outside, intermediate elements are reinforced with spacers.

- A cover for the pool is cut out according to the size of the frame. The film can be glued or welded if necessary. Lay the film in the pool bowl, bringing the edge over the edge of the side by at least 20 cm.

- Install drain holes. The outlet pipe is connected to the sewage system, and the leading pipe is connected to the water supply in the house.

- Fill the pool with water at least 20 cm in order to check the effectiveness of the communication work and waterproofing. The film expands under the weight of the water.

- Stiffeners, belts, and other clamps are installed.

If necessary, the outside walls of the pool can be insulated, and then repaired with clapboard or boards.

Care and maintenance tips

The plank pool needs maintenance.

- Do not leave the reservoir full during the cold season. If in winter the temperature drops much below zero, it is better to disassemble the entire structure.

- Wooden elements should be periodically treated with antiseptics, impregnated with drying oil.

- Make sure that when emptying the bowl, the water completely leaves the reservoir.

A wooden pool is a very unusual solution. Unlike a concrete structure, it can be made and installed independently, but it does not last long and needs maintenance.