Turkish baths are becoming more widespread in Russia. They differ from the usual steam room temperature regime, which has a special effect on the body. You can organize a hammam in a bath with your own hands if you have suitable premises and funds for equipment.

What is Turkish Bath

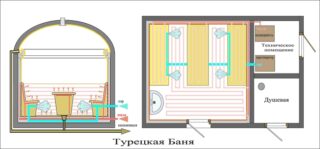

Having decided to build a home hammam, you need to have an idea about the structure of the future premises. In Turkey, it consists of at least three sections - a dressing room, a bathroom and a place where the main procedure takes place.

Often there are other areas for visitors to rest in the building. When building a hamam with your own hands for private use, they are usually limited to three rooms.

The hamam differs from the usual steam room and Finnish sauna in a low-temperature regime with high, close to 100%, air humidity. This is suitable for beginners and those who do not tolerate hot steam well. Even in the main room, the temperature, as a rule, does not rise above 50-60 degrees. In the washing room, it is 30-35 degrees.

Advantages and disadvantages

Thanks to the gentle temperatures, getting used to the procedures is faster than to a regular bath. The stress level for the body is noticeably lower. At the same time, profuse sweating allows you to remove harmful substances and relieve the kidneys.

There are categories of diseases for which the hamam is contraindicated:

- fungal and pustular skin lesions, eczema, psoriasis;

- any acute inflammation;

- oncological processes;

- cardiovascular diseases.

Equipping a hamam in a house with your own hands is not so difficult if there is a suitable room. From the point of view of construction work, the disadvantages of such a bath are a large load on the base of the building and floors, as well as the cost of resources for equipment and installation work.

Technical equipment

It will not work to convert a standard wooden Russian steam room into a hammam. This is due to the significant load on the foundation. For wooden baths, which are lightweight buildings, an appropriate base is usually organized.

If the steam room is built of brick or block material and the foundation is massive, it can be converted.

A hammam in a private house can be designed as a free-standing room or as an extension to a residential building. In any case, it is important that the foundation can withstand the loads generated.

Do-it-yourself hammam in the apartment, assigning a room for it, equipping it with ventilation and the proper level of heating. Due to the limited space in this case, sometimes a minimum set of equipment is dispensed with. You can equip a hamam in the country.

A steam generator is used to generate steam. If there is a utility room, it is usually mounted there. To maintain a constant temperature in the steam room, an automation unit is equipped with sensors oriented at 50-55 degrees. It is better to purchase a steam generator with a remote control - this will facilitate its operation.

Heating of the room can be water or electric. In the second case, installation work is easier, but you will have to pay more for electricity. The IP rating must be at least 65.

Space requirements and choice of materials

Having decided to make a hammam with your own hands in the country or in a living room, you need to know about the requirements for a steam room. The ceilings should have a height of 2.5-2.6 m. In a classic hammam, they have the shape of a dome, but when organizing a bath in an existing room, this can be neglected. The foundation and floors must be able to withstand significant loads.

The building can be erected from bricks, gas or foam blocks. Traditional buildings are laid out of stone, but due to the high cost of material for summer cottages, it is rarely used.

Before making a hammam, it is important to choose a finishing material. It must be resistant to moisture and high temperatures, not emit harmful compounds when heated. Glass mosaics, ceramic tiles are suitable.

Construction stages

It is important to prepare a project for the premises. On the diagram for construction, they indicate the location of rooms, the paths for laying heating and water supply cables. If the bath is done in an existing building, the surfaces are cleaned to a block base and covered with an antiseptic.

Below is a step-by-step guide to self-equipping a hamam in an already erected block building. Before starting work, you need to make sure that the foundation will withstand the expected load.

The arrangement of the steam room begins when the main work on the finishing of the premises is completed: concreting and arrangement of the subfloor. First you need to lay engineering networks - water supply, sewerage system, organize heating.

Heating system

Most often, they equip electric heating according to the principle of a warm floor. A water floor is rarely made due to the more difficult installation and an increase in the already significant load on the foundation. Heating wires can be installed not only on the floor, but also on the walls. The surface is covered with hydro and then thermal insulation and the cables are mounted, fixing them with a special tape. Then the reinforcement is laid and a screed 3-5 cm thick is created.

Heating system

To maintain humidity, a steam generator is used, the principle of which is similar to that of an electric kettle. The design includes a heating element and a water tank. You can buy a steam generator to make sludge yourself.

How to make sun beds

In a traditional hammam, the loungers are not straight, but rounded. You can make them yourself from PSB-50 and PSB-35 foam.

Step-by-step manufacturing instructions:

- The lounger is molded with a knife and a device for cutting foam.

- The surface is reinforced with a mesh structure made of fiberglass with a density of 145 g / m², planted on an adhesive (Ceresit CT 85 or similar). The mesh should be completely immersed in it.

- The seat is tunneled to install the heating. It also needs to be reinforced.

- Liquid waterproofing is applied in 2-3 layers.

After the composition has dried, the surface can be tiled with a mosaic. This design can withstand pressures up to 250 kg / m².

Lighting

Only moisture-resistant cable products are used for wiring. The products are placed in a corrugation that is resistant to high temperatures. Low-voltage LED bulbs are used for the luminaires. The design of the devices must be suitable for rooms with a large amount of steam.

Decorative finishing

Due to the very high air humidity, a very limited number of materials can be used for interior cladding. Ceramic tiles and natural stone are best suited.

After washing, the body is warmed up on the lounger until sweat drops. Then the skin is lubricated with oil and massaged in woolen mittens. After the session, the body is washed with soap and the procedure is completed with a cool shower that tightens the pores.