When arranging a garage, you need to decide which roof structure to prefer - single or with two slopes. The second option requires less waterproofing, since water flows from the surface in a timely manner, and is suitable for regions characterized by an abundance of precipitation. To make such a structure, you need to have an idea of the correct technology for erecting a gable roof on a garage with your own hands.

Advantages of a gable roof

A pitched roof is often preferred by homeowners due to its simplicity of construction. However, it has one drawback - susceptibility to temperature changes. Such roofs are more prone to violation of the vapor barrier, which causes condensation to accumulate inside the building, which adversely affects the condition of the garage.

The design with two slopes ensures the timely removal of moisture from the surface. It is evenly heated by the sun; snow masses do not linger on it in large quantities. It is convenient to store equipment and tools in the attic.

The gable structure has a longer hood length, which improves ventilation. However, this applies to residential buildings and not to the garage (no pipe is installed in the latter).

Design of a gable roof

When choosing a coating for a gable roof, it is necessary to take into account what material the room itself is made of - cinder block, foam block, brick, etc. In addition, the angle of inclination of the structure is also important. Dense materials with a minimum number of joints (including rolls) are suitable for roofs with low slopes. Shingles, on the other hand, are laid on steep roofs. The smaller the dimensions of the elements, the more the slope should be.

Before proceeding with the purchase of materials and starting to make a roof, it is necessary to prepare a drawing representing its structure. It indicates the main elements with their dimensions.

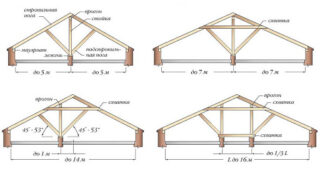

For a structure with two slopes, two main types of rafter systems are used - hanging and layered. The first is suitable for a small garage for one car, the second - in a building where there is a need to cover a large span (for example, equipped with a pair of boxes for a car).

The slanting version assumes the presence of strong supports at all rafter legs from above and below. In the latter case, these are usually the walls of the building. The tops of the rafters are supported by the girder system, and the latter is supported by an internal wall or several supports placed in the room. Therefore, this option is not practiced in small garages: support posts and walls "eat up" a lot of useful space. They begin to build such a roof by creating a frame with a ridge girder. It will serve as a support for pairs of rafters.

Hanging structures are usually built by installing special trusses in the shape of a triangle. You can make them yourself or purchase them ready-made. The technology assumes that the rafters are supported exclusively on the walls of the box.

The execution of both types of structures for small spans (5 m or less) is simple and concise. For larger roofs, the system becomes more complex, additional supports and other elements appear.

When the roof is built over the frame walls, the rafters are not attached to the garage Mauerlat, but to the upper strapping of the supports.When preparing a project, do not forget about this feature. The tabs for fixing the Mauerlat are organized during the construction of the walls. You can also find roofless roofs for the garage. In this case, the emphasis is on triangular pediments made with brickwork.

The angle of inclination depends on the weather characteristics of the region - the amount of precipitation, the presence or absence of strong gusts of wind. The angle of inclination also affects the choice of roofing material. In windy areas, the roof is made long and shallow. In areas where there is a lot of snow, the opposite design is preferable - a high one with a large angle of inclination. When choosing, it is also taken into account whether the owners want to equip an attic or an attic under the roof.

Materials and tools for manufacturing

For a roof with a wooden truss system, you will need the following tools:

- saw;

- a hammer;

- ax;

- instruments for measuring and controlling evenness - building level and tape measure;

- mallet.

You also need to prepare the required amount of roofing material. If corrugated board or other sheet metal coating is selected, special cutting scissors are required. Self-tapping screws, staples and simple nails are used as fasteners.

The main elements of the roof structure and their installation

Work begins with the preparation of the rafter system. Then the crate is mounted and the roofing material is laid on it.

Rafter system

First you need to decide whether you plan to create an attic or an attic under the roof. In the first case, the system will require additional reinforcement with the help of racks vertically attached to the Mauerlat. In this case, the step should be no more than 0.9 m. The connection is carried out using staples. If it is decided to make an attic, the rafters are mounted directly on the Mauerlat. Most often, this is done so that their lower parts hang over the building by about 0.5 m. But sometimes these parts are the junction with the Mauerlat.

Metal rafters are remarkable for their strength and long service life. They perfectly tolerate dampness, temperature changes and other features of the garage microclimate. But the large mass does not allow them to be used in light frame buildings. Such rafters are suitable for a fairly heavy garage with a solid foundation. Before installation, they must be treated with an anti-corrosion compound.

Wooden rafters are also suitable for light structures, but it is important to choose the right material to increase the service life. Pine and spruce are suitable as raw materials. The lower the moisture content of the wood, the better. The maximum allowable value is 20%. Natural moisture material is not suitable, since its indicator is in the region of 30%.

The rafters should not have cracks or knots. Glued laminated timber is better than solid timber due to its greater strength. The material must be impregnated with fire retardant and antiseptic compounds. Usually, legs with a section of 15x7 cm are purchased for a garage room. If possible, it is better to order special wood intended for rafters.

Fortifications and plumb lines

To create an overhang, filly are nailed to the rafters - additional boards. If the rafters are not long enough (shorter than 8 m), a capital beam is nailed to the ridge, which helps to fix the structural elements. From above they are lined with waterproofing, and then lathing slats are nailed. If slate, metal tiles or other material of high hardness is chosen as a covering, the frame is made sparse. The distance between the first pair of rails is made small (maximum 0.25 m), between other elements - no more than half a meter. The parameter value is also influenced by the profile step. For a soft roof, you need a continuous sheathing without gaps.

Roof covering

Features of the installation of the coating depend on its type. The slate begins to be laid on the underside of one of the slopes. The first row of sheets is laid with an overlap of 1-2 waves. Then they move up, while a new row is placed on the lower one with an intersection of 0.2 m. The sheet materials are mounted on a counter lattice with a vapor barrier layer. This prevents the accumulation of condensed moisture. The strips of roofing material are laid at right angles to the edges of the roof, pulled and installed with an overlap, fixing with special nails.

Interior decoration

Mineral wool in rolls is well suited for insulation. Its layers are laid between the rafters; umbrella-type dowels are used for fixing. Then the vapor barrier material is mounted. The ceiling can be finished with plasterboard, PVC sheet or plywood. The suitable paint for the selected type of material can be selected in the construction shop. The package contains step-by-step instructions for applying it. Before painting, the surface is treated with a water-repellent compound.