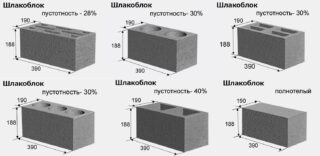

Blast furnace slag blocks are an inexpensive material used in residential construction and for the construction of garages and other industrial buildings. They are solid and hollow (with holes in the middle). The second option has a lower mass and is used for the construction of walls. Before starting work, you need to prepare projects with the dimensions of a garage from cinder blocks.

- Advantages and disadvantages of a cinder block garage

- Project and preparatory work

- Selection and marking of a place for construction

- Calculation of the amount of cinder block

- DIY construction stages

- Foundation construction

- Observation pit

- Base / plinth device

- Building walls

- Roof and gate

- Floor screed

- Network engineering

Advantages and disadvantages of a cinder block garage

Often a sand block garage is the preferred option due to the quick completion of the work. The products are large, which also speeds up the process. Also, the material has the following advantages:

- good refractory properties;

- small price;

- long service life of the finished structure (up to half a century);

- less consumption of cement slurry compared to the situation when it was decided to build a brick building.

The disadvantage is the large weight of the blocks (especially full-bodied ones), as well as the likelihood of the presence of toxic elements in the composition. Because of this feature, the cinder block is considered not the best choice for the construction of a residential building. For the production of the material, waste of different quality and origin can be used, therefore, before purchasing, you need to make sure that it complies with environmental standards.

The type of filler also matters. The safest options are shell rock, expanded clay chips and sawdust. Granite screening is best avoided - it can be radioactive.

It is better to build a garage on soil that is not distinguished by high humidity, and revet the walls with waterproof material.

Project and preparatory work

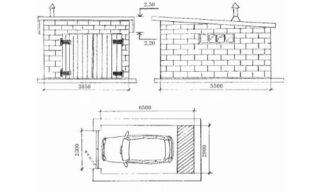

Before starting work, it is worth preparing a drawing indicating the main dimensions and places for laying communications. If the landlord has two cars or plans to buy a second one, it is possible to make a space for 2 cars.

If you intend to use the garage for repair work, you can equip it with a basement. If it is planned to place a workshop in the room, the dimensions increase depending on how much equipment will be inside.

Selection and marking of a place for construction

Before you build a garage from a cinder block with your own hands, you need to prepare a site. Garbage is removed from the territory (including those buried in the soil, as well as large rhizomes) and leveled using a water level. It is necessary to survey the area for the presence of gas or water pipes, as well as cable routes. If this is not done, problems will arise when digging a viewing hole or when dismantling tracks and installing new ones.

The foundation tape is marked out, focusing on the drawing. The outline along the length of the perimeter can be formed using beacons. Internal and external corners are marked with rods. The depth relative to zero (ground level) must match the data in the drawing. It depends on the design features of the garage, but in any case it should be at least 0.6 m.The minimum value of the tape width is 0.3 m.

Calculation of the amount of cinder block

Before you build a garage from a cinder block with your own hands, you need to take care of the correct calculation of the volume of material.To do this, you need to know the dimensions of the walls of the planned building, as well as the dimensions of the unit of the module. You can take measurements at the time of purchase, or rely on the information provided by the manufacturer.

First you need to find out the area of the walls. For this, the perimeter of the garage is multiplied by its height. The area of the gates and windows (if any in the building) is subtracted from this value. The resulting number is divided by the selected number of blocks per square meter (it depends on the area of one block and the type of masonry). The result is rounded up. It is advisable to purchase material with a certain margin, since damage to several block units is likely during the work.

For work, you will need a tool for preparing a construction mixture - a concrete mixer or a mixer. Of the equipment, a perforator is also needed. You will need a shovel, hammer, fasteners, tools for measuring and controlling evenness (square and construction tape).

DIY construction stages

The stages and rules for building a garage from a cinder block with your own hands are generally the same as for other household structures made of block materials. They start with the preparation of the foundation.

Foundation construction

If the soil at the construction site does not differ in heaving, flowability, high moisture content, you can equip a strip foundation. Otherwise, a pile is better suited. The depth of the tape depends on the type of soil and the mass of the building. It is best if the foundation is made below the freezing mark. At the bottom of the trench, a sand cushion of 0.3 m is organized, on which a layer of rubble of about the same height is poured. The plank formwork is lined with polyethylene so that the wood does not swell from moisture. For reinforcement, rods with a cross section of 12-16 mm are used.

Observation pit

If the garage project includes an inspection pit, the foundation is equipped at a greater depth. You should take care of high-quality waterproofing - this will protect the structure from the action of groundwater.

Base / plinth device

After the concrete has hardened (it takes about a month), the foundation must be covered with roll waterproofing. This is done so that the material extends a few centimeters beyond the boundaries of the base. You can lay the walls in a single block, in half, in two or one and a half.

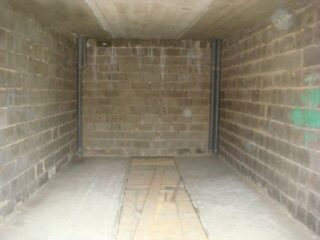

Building walls

First, the corners are set - they should form a rectangle or square. Smoothness can be controlled with a taut cord. Having completed the constriction, they continue to mount the blocks. Their masonry is similar in principle to brick.

Roof and gate

The most reliable roof beams are steel I-beams. Due to their high cost, in practice, beams are often made from antiseptic-treated bars. Planks are mounted on them, lined with a waterproofing layer and roofing material is fixed. The easiest way to make the gate is swing.

Floor screed

Having removed the soil layer and tamped the bottom, they equip the sand-crushed stone pillow. After installing the reinforcing cage, the concrete mixture is poured to the level of the base.

Network engineering

If the premises will be used for car repairs, it is necessary to provide high-quality lighting in it. The system includes a transformer that lowers the voltage to 12-36 V. The sockets are connected to the line strictly in the junction boxes.

For the exterior decoration of the garage, a special facade paint is suitable. The packaging usually contains step-by-step instructions for its use. From the inside, the walls can be sheathed with clapboard.