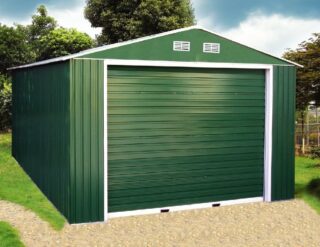

One of the conditions for extending the life of the car is its maintenance in a comfortable environment. The technique does not tolerate prolonged exposure to dampness, direct sunlight and temperature drops. A well-designed frame garage made of metal profiles can provide an optimal environment for the car. To achieve a quality result, you should familiarize yourself with the range of available materials and the technology for their use.

What is a metal profile

When deciding to build a garage from a metal profile with your own hands, you should familiarize yourself with the varieties of products.

To make a frame or frame garage, pipes with a square or rectangular cut are used. The section size varies from 10x20 mm to 100x100 mm with a wall thickness of 1-3 mm. The length of the profiles produced starts at 200 cm and ends at 600 cm in 100 cm increments. Iron pipes are used to erect the frame of the walls, entrance gates, doors, ceilings and rafter systems.

Another type of rolled steel is profiled sheet (corrugated board). The blanks are cold formed, during which they are given a wavy shape, where the configuration and height have certain parameters based on the scope of the coating. The canvases are coated with various substances that protect the metal from corrosion and give it a presentable appearance.

To build a garage from a profile with your own hands, the following types of profiled sheet are used:

- carrier;

- wall;

- bearing-wall;

- roofing.

There are also such options for external coating (in order of increasing protective properties):

- zinc;

- zinc-aluminum;

- polyester;

- polyvinyl fluoride;

- pural.

The cladding is applied to both or only one (inner or outer) side of the panels. You can learn about the technical characteristics and purpose of the material from the informative marking and instructions for use applied to it.

Pros and cons of the material

Having decided to build a garage from a metal profile, you should familiarize yourself with the positive and negative properties of this material.

The advantages include:

- Presentable appearance. Budget models look modest, but quite decent.

- Non-flammability. Sheets reliably block open flames. To burn them out, you need at least half an hour of intense heat.

- Sufficient resistance to mechanical stress due to stiffening ribs. You can cut through the sheet only with heavy tools.

- Lack of hygroscopicity. Products absolutely do not absorb and do not allow moisture to pass through.

- Ecological cleanliness. The composition of the coatings does not include substances harmful to the environment.

- Low specific weight in comparison with other types of finishing materials

- Affordable cost even for prestigious coatings.

- Long service life, reaching 30 years.

- Ease of handling and installation.

Cons of material:

- Corrosive tendency. The ends of the sheets do not have a protective coating.

- External application is not durable, it is easy to scratch and wrinkle.

- The paint fades in the sun. After 3-4 years, it becomes dull and faded.

- Iron heats up and cools down a lot, transferring the temperature to the space of the room.

- Good sound conductivity.When it rains, the roof makes a very loud noise, which can even block people's conversation.

Some developers are inclined in favor of capital construction from bricks and foam blocks, while others believe that a light, inexpensive and pre-fabricated building is better. Both points of view have a right to exist, since each sets his own priorities.

Drawing up a drawing

The options are:

- for one or two cars;

- gable or gable roof;

- swing gates, lifting, sectional, with or without a wicket;

- warm or cold garage;

- the presence of a cellar, inspection pit, second floor, attic.

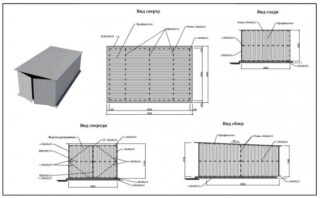

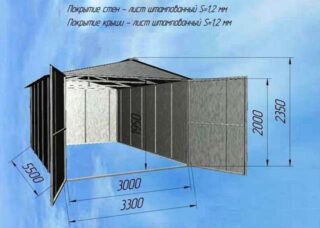

After deciding on the layout, sketches are made and then detailed drawings. They are compiled manually or using one of the computer programs: AutoCAD, nanoCAD, Compass, Solitworks, 3-D MAX. A separate diagram is made for each node, indicating all the details and nuances.

Budgeting

Typically, a standard schema includes the following sections:

- list and scope of work;

- quantity and cost of materials;

- fare;

- overheads;

- the total cost of work and materials.

It is recommended to purchase property with a margin of up to 15%. This is necessary to cover losses due to errors, damage during storage and transportation.

Required materials and tools

To build a garage from a profile, in most cases, the technical arsenal available to the owner of the land plot is enough.

Instruments:

- level;

- roulette;

- shovel;

- Bulgarian;

- welding;

- screwdriver;

- a hammer;

- ax;

- concrete mixer;

- ladder.

From the materials you need to purchase:

- shaped pipes;

- professional sheet;

- fittings;

- sand;

- cement;

- fine and medium gravel;

- hinges for hanging gates and wickets;

- locks and bolts;

- self-tapping screws;

- bolts with nuts;

- insulation;

- plasterboard for cladding;

- formwork panels.

To prevent injury, you should use welding clothing and a mask, goggles, gloves and a respirator.

Garage construction technology from a metal profile

Subject to good weather and timely delivery of materials, a garage can be built within one to one and a half months. If you use screw or driven piles under the foundation, even faster.

The work is carried out in the following sequence:

- Site selection and preparation. Since the garage is a place of increased danger, it is positioned with this feature in mind. The distance to your home should be at least 3 m, and to the neighbor's - 6 m. It is better to choose an elevated area so that the building does not flood with melt and storm waters. It is contraindicated to conduct construction over underground or air communications.

- Arrangement of a cellar or viewing pit. You can use ready-made products or create them yourself. Red baked brick or reinforced concrete is used as a material for the floor and walls. The staircase is made of metal or wood.

- Pouring the foundation and floor. A frame garage weighs little; there is no need to make a powerful base for it. The simplest solution is to fill in an insulated slab 40 cm thick. If you make a deepened strip foundation, you can equip a basement in it. Piles allow you to make the foundation quickly, but after that you will have to equip the grillage, slab and ramp.

- Erection of the frame and walls. First, the bottom trim is fixed to the foundation. Then you need to screw or weld vertical posts to it.Then you need to weld the top harness and the lattice frame. The distance between the vertical elements is matched to the width of the sheets, taking into account their overlay on one wave. For a pitched roof, the upper harness is made with a slope of 30 degrees towards the rear of the building.

- Roof installation. In an insulated building, a layer of insulation with a membrane sheet is first made. Then the lathing is installed and the covering is laid.

- Fastening sheets. The panels are positioned vertically and screwed to the frame using special fasteners with a drill and a silicone washer. Installation is carried out from the bottom up, the joints are insulated with facade sealant.

- Gate installation. First, a frame is made from a profile pipe, then a frame for the sashes. After precise adjustment, the structures are connected with loops. Sheathing and insulation of cloths, installation of locks and constipation is carried out.

The final stage is the supply and connection of communications, interior decoration of the premises.

Maintenance of a steel frame garage is not particularly difficult, but should be carried out regularly. During operation, the building must provide good ventilation and dehumidification after the appearance of condensation. The bolts should be checked and tightened periodically. In spring and autumn, it is necessary to remove corrosion and paint over the areas cleared of it.