Wickets and gates made of metal with an openwork structure are distinguished by their elegance and artistic design. In addition to external aesthetics, structures protect private territory from illegal entry. The products are representatives of the premium segment. Organization of forged gates with your own hands reduces the burden on the budget. Self-production requires welding skills and knowledge of technology.

Varieties of forging

To make gates with forging elements with your own hands, you need to choose the type of forging:

- Cold type. Material processing is carried out without preheating. Craftsmen use stamping on special equipment. The finished parts are formed into a single structure. Affordable welding option involves the use of only typical design solutions.

- The hot look is characterized by painstaking work. Labor-intensive processing of metal products is carried out using tools. As a result, the master creates an exclusive item.

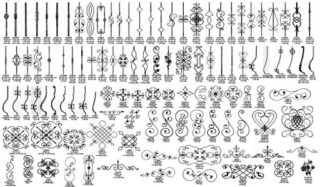

In the absence of skills in blacksmithing or equipment, you can use ready-made elements to create a forged gate with your own hands. Details are widely presented in stores - at the user's choice patterns, sizes, design solutions that match the exterior of the house. After purchasing the selected elements, it is enough to weld into a single composition.

Stylish solution for wrought iron gates

A typical gate is converted into a main entrance when created in the Baroque or Renaissance style. Such designs will be an adornment to the house, country cottage or estate. As a rule, benches, gazebos, fences are additionally equipped with forged decor to create a single ensemble. The elements are made in the form of spirals and curls.

A modern look to the exterior is given by the Art Nouveau style, which implies the use of simple, intersecting lines. The design creates airiness and lightness. Choosing the direction of minimalism, you can not only save on forging, but also create piercing asceticism.

Do-it-yourself wrought iron gates for a private house are also made in the art deco style. This design direction is distinguished by its strict geometry. Ornaments decorate the front entrance, both to the house and to the apartment. For the manufacture of structures, this involves the method of cold welding.

Preparatory stage

Before erecting a forged gate with a wicket with your own hands, you need to take into account the parameters of practicality and safety. The design should match the style of the home and landscape. The drawing will help to combine these criteria, on which all the elements of the site are applied, and the location points are also marked. You can make the scheme of the future front entrance yourself or use a ready-made project.

In the sketch for a gate made of a profile pipe with do-it-yourself forging elements, display the following details:

- frame diagram;

- installation elements;

- connecting awnings;

- decor;

- lock and bolt.

Also reflect the sash configuration and dimensions in the drawings. Decide on the shape of the structure - a rectangle, a broken top, the presence of a radius, and more.In addition to the dimensions, include in the sketch information about the location of the stiffeners, the spacing between them, and other details. On the drawing, mark the type of fastening of the gate to the fence and wicket.

Calculation procedure and list of instruments

Independent production of forged elements for gates or wickets requires special equipment and auxiliary materials. Prepare the following tools for work:

- a furnace or furnace for forging at home;

- anvil;

- a grinder with a disc for polishing iron;

- welding equipment;

- big and small hammer;

- ticks;

- machine;

- curved yews.

If there is a solid fence and a desire to close the area from prying observation, use the shutters, profiled sheet, polycarbonate or wood.

Instructions for self-production of forged gates

After preparing materials and equipment, study the technology and nuances of installing metal structures. When making a forged gate for a private house with your own hands, as well as a gate, it should be remembered that at the end of the work, all the details will increase in volume. Experts recommend that all springy elements be pre-baked, heated and cooled - this will make the metal more malleable.

Installation of supports

For the pillars, dig one-meter recesses 10 cm wider than the dimensions of the supporting elements. After installing the pipes from the profile, fill the holes with gravel - carefully tamp every 20 cm of the layer. Experts recommend that you regularly check the perpendicularity of the posts in order to avoid distortion of the sashes. At the final stage of installation, fill the surface around the racks with concrete.

Assembling the structure

Prepare a straight surface for laying the elements in one plane. Connect the flaps of the prepared pipe parts. Place the lower part at a 90 ° angle. Weld metal corners to secure the sash. Weld a rectangle from the parts and set it in the central part as a stiffener. Fix the structure and, using spot welding, install the corrugated board.

At the top of the sashes, cut the steel sheet with a grinder to give the structure an appropriate look. Hang the swing elements on the posts with special hinges. At the end of the welding work, grind the seams.

Making spiral rods and lances

Cut the blanks to create the peak. Cut the metal profile sheet into squares and grind it to shape the product. After warming up the part in the forge, clamp it in a vice and turn it at the desired angle. Each turn is one turn. The processing process ends with straightening. At the end of the work, compare all the blanks and connect them together.

Decor with ready-made elements

In stores, you can buy ready-made forging elements - solid ornaments, peaks, ruffles, inserts and much more.

Place the welded frame on the work surface. Check build quality and corner accuracy. Weld the finished forged elements at three points or create a broken line - depending on the chosen design. Align the workpieces with the profile and secure with welding or clamps. Grind the parts with a grinder.

Painting

The main condition for the aesthetic appearance of forged gates is the protection of the metal from rust and precipitation. Only with this approach will the paint last for many years without any defects. For these funds, special compositions are selected for working on metal. Anti-corrosion paintwork also hides small irregularities from welding.

Apply a deep penetration primer before painting, then spray the gate. For color, use a tone that matches the exterior of the house and landscape. Highlight the forged parts in a separate color. For example, if the canvas is brown, then peaks and curls can be processed with bronze.

When installing the gate, adhere to the work algorithm.First of all, pillars are mounted, then points are marked for future gates. The support posts are immersed to a depth of 1 m. After 2-3 days, they are hung on the hinges of the sash.