In two-storey private houses and cottages, stairs are indispensable. Arranging a straight one-flight staircase is not always the best option. This design takes up a lot of space, and with an increase in the steepness of the march, its use becomes simply inconvenient and sometimes unsafe. In this case, a staircase to the second floor with a turn is the only way out of this situation. Swivel structures can have a swivel angle ranging from 90 to 180 °.

Types of rotary flight stairs

Swivel stairs are composed of several flights and equipped with platforms between them. There are such types of structures:

- L-shaped - flights of stairs are connected at an angle of 90 °;

- U-shaped - consist of two marches connected by a platform that is located between them or at the floor level;

- 3-sectional - assembled from three flights at an angle of 90 ° relative to each other;

- trapezoidal - designed for installation in non-standard rooms;

- rounded - curved staircases with a rotation angle of 360 °;

- combined - consisting of elements of different types.

The method and place of installation of rotary structures is chosen based on a number of factors:

- ease of placement of flights of stairs;

- the ability to mount turntables;

- free access to stairs, etc.

The turning platform for the stairs does not always have to divide the latter into two equal parts. Only a few steps can lead to it, and then the main march begins. In this case, the structure may not have a turntable - it may well be replaced by winding steps.

Winder stairs can be:

- screw;

- collected on one stringer or bowstrings;

- U-shaped, which, unlike stairs with turntables, are fully rotated 180 °.

Each of the designs has its own advantages and disadvantages, but they are all compact and save living space.

Basic requirements for winder stairs

The main conditions that stairs with turning steps must meet are comfort and safety. They are ensured by the fulfillment of the basic technical requirements inherent in winder structures and stipulated by GOST.

- the turning steps of the staircase should be located at the same distance from each other;

- the number of steps of winders should not exceed 18;

- the depth of the run-in step of the narrow section of the step should be 10 cm, while in its central part this value is approximately 20 cm, and in a wide section it does not exceed 40 cm;

- the overhang of the winding steps should not be more than 5 mm;

- the swivel staircase is equipped with handrails, the height of which is usually from 0.9 to 1.2 m;

- a staircase with a turn should have a comfortable angle of inclination of the order of 30-45 °;

- the ceiling height above the swing staircase is at least 2.0 m.

The steps of the winders can be located in different parts of the span - lower, upper or in the middle.

Design and calculation of winders

A staircase with run-in steps is a rather complex and complex structure with characteristic features that cannot be neglected in the process of preliminary design and drawing of drawings. Therefore, before starting the design, you need to:

- Determine clearly the location of the stairs.

- Measure with high accuracy the height from the floor to the second floor and the width of the staircase.

- Decide on the design of the stairs and the exact number of steps, as well as make a list of materials that will be needed during its construction.

- Drawings are developed, guided by the results of the measurements obtained.

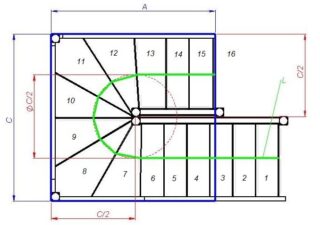

Determining the dimensions of the L and U-shaped winders, the method of proportions is most often used. They do it as follows:

- In the drawing, in the middle of the march, a line is drawn on which segments corresponding to the width of the step are marked.

- Mark the border between normal and winder steps.

- Find the middle of the turning area and draw a line from which half the size of the winder steps is laid.

- The number of straight steps is subtracted from the calculated number of steps, while controlling the depth of the tread in the middle section of the march.

If the tread depth indicator obtained as a result of calculations is less than the recommended one, the number of steps must be reduced.

Independent production of winder stairs

Modern staircases can be wooden, metal, concrete and even glass. Often there are designs in the manufacture of which different materials are used. Moreover, their supporting frame is made of metal or concrete, and the steps can be, for example, wooden or glass.

The most popular are wooden staircases with a turn to the second floor. They are much lighter than other designs and differ from them in beauty and grace.

When making winding staircases, special attention should be paid to the quality of materials. The use of low-quality products will lead to the fact that the structure will turn out to be short-lived, and in some cases even unsafe in operation. When choosing materials, it is imperative to inspect them visually for the presence of various kinds of defects and damage. After making sure that they are absent, you can proceed to familiarize yourself with the accompanying documentation.

Step-by-step instruction

Despite the apparent complexity of the design, a wooden staircase is also erected with their own hands. This process begins with the manufacture of kosour, for which a special template is made, using which it is easy to perform this operation.

Further, it is advisable to follow the step-by-step instructions:

- A special groove is hollowed out in the post on which the kosour is attached.

- The base for the winder steps is mounted on the wall.

- At the top of the stairs, using metal corners, stringers are attached opposite each other. Otherwise, the staircase will turn out to be curved.

- Winders are cut out of a pre-prepared and marked panel. In this case, the marking lines should go from one corner of this workpiece. The length of the cut steps must be the same.

- Collect the entire structure. To attach the steps to the post, special grooves are cut out in the latter. If they turn out to be too wide, the steps in them will not hold.

- Swivel steps are lubricated with glue and fastened with self-tapping screws for reliability. It is recommended to do the same with straight steps.

- Having finished the installation of the steps, they proceed to the installation of the railing. There are several ways to attach them, for example, by screwing them to the steps with self-tapping screws. Another option is to attach the railings to the steps using dowels. For this, holes are made in the steps, they are filled with glue and dowels are inserted there.

- After completing the installation of the posts for the railings, they are cut off. To do this, pull the cord along all the balusters and securely fasten it between the first and last posts.The cord marks the level at which the balusters are cut.

- A handrail is attached to the cut posts with self-tapping screws.

The frames of similar stairs are often made from sections of a metal profile, welded to the shape of the intended structure.