The drainage of water from the steam room and the washing room is needed so that moisture does not spoil the floor boards, log structures, beams. The method of draining the water in the bath is chosen depending on the frequency of use, the type of soil and the winter air temperature. If the family is rarely steamed, it is enough to make a pouring floor, and the water will go down into the ground or drainage. With intensive use, equip a sewer system with a cesspool or septic tank.

- General rules for arranging drainage

- Types of plums

- Drain well

- Drainage well

- Installing a septic tank

- Connection to the central sewerage system

- What way to drain water to choose

- Rules for arranging a drain pit

- Advantages and disadvantages

- Construction technology

- Rules for arranging a drainage well

- Pros and cons

- Self-construction of a drainage well

- A septic tank as a drainage system

- Pros and cons

- Construction technology

General rules for the arrangement of drainage

For the manufacture of the floor, concrete and wood are used. In the first case, they make a slope and a sewage system, which leads the drains into the pit.

For plank flooring, there are two options:

- Leaking floor. Planks are spaced or holes are made in the deck. The liquid flows freely into the ground. A variation is the device of a clay castle (a layer of rubble and clay with a slope) under the floor or drainage from sand and rubble.

- Non-leaking coating. Planks are placed close to each other with a slope, while in the lower part there is a receiving bowl for collecting and redirecting the flow into a pit or sump.

The continuous version of the drainage system requires a ventilation gap and insulation. In the flowing version, insulation from the cold is not installed, more fuel is required to maintain the heat in the bath.

Types of plums

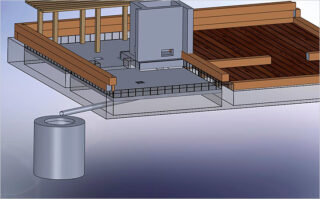

The volume of the discharged liquid depends on the area of the bath, the set of premises. In small buildings, the steam room is combined with a shower, the floor area allows you to make the simplest drainage. In this case, a foundation is made in the form of pillars, screw or driven piles.

The following forms of organization of the drain are used:

- acceptance directly into the ground;

- drainage wells diagram;

- cesspool;

- system of several settling tanks;

- common sewerage.

Large bath complexes require the connection of collectors, since the amount of water becomes significant. The ground under the floor will not be able to absorb it intensively, especially if there is clay soil there. In winter, the soil freezes, so the direct drainage scheme cannot be used.

Combined drainage methods are more functional, since they do not allow the appearance of fungus, mold and rot on the boards, they quickly drain liquid from the washing area.

Drain well

To arrange the drainage of water from the bath, a pit is made, which is lined with bricks, concreted or placed in a plastic container. Water is supplied to it from the drainage zone through a pipe. The pit is cleaned using special machines, which are ordered when the well is filled to the top.

The drain collector is made of plastic, it is installed at a slope. A hole is made in the floor of the concrete steam room, which is connected to the sewer pipe. Water flows freely into it, goes into the ground or accumulates in a sealed container.

The second variant of drainage is considered cumulative, its walls protect the surrounding space from water ingress. It is allowed to build it no closer than 5 m to a residential building.

Sometimes there is no solid foundation at the bottom of the drainage structure, but there is a crushed stone drainage pad. Water seeps through such a layer, therefore, at least 12 m is made to the residential building. The rule applies to the location relative to the neighbor's house.

Drainage well

It is an engineering structure in a closed drainage scheme. Several such cleaning elements are installed in the system to monitor the functionality. The drainage well is a water intake, it is used to transfer water from the bath directly into the ground.

Water enters the receiving container by gravity or under the action of a pump. At the bottom they make a bed of sand and gravel. Gradually, the layer becomes waterlogged and stops letting water into the ground.

The system will work flawlessly if it is periodically cleaned of any mud deposits on the bottom. For this, the crushed stone is raised to the surface and washed from the silt. Sometimes the layer is simply changed with new rubble or gravel to simplify the procedure. In another embodiment, water is supplied under pressure and the sludge is raised to the surface of the water mass in the pit, then the silt film is drained or pumped out.

Installing a septic tank

The settling tank for water purification can be multi-chamber or has two chambers. Sometimes they are made in the form of adjoining wells with a common wall and an overflow hole. If there is not enough space for the installation of a monoblock complex, they provide for the location of the containers close to each other, while the liquid between them passes through the pipes at an angle.

The arrangement of the septic tank is laid at the design stage of the drain device in the bath. The sump is used in the absence of a central sewerage system. In the first container, heavy particles are precipitated by gravity. At the top of the first compartment there is a hole with a grate through which water, when filling, begins to flow into the second, where the secondary settling of particles takes place.

The third tank uses the principle of biological post-treatment. Special bioferment agents are introduced that decompose microorganisms and purify water.

Connection to the central sewerage system

The method is beneficial, since you can save on materials and work on the arrangement of an autonomous circuit.

Connection advantages:

- no need to carry out self-service of the system;

- there is no need for design, since the pipes are connected by specialists of the service organization, they also monitor the quality of the system.

The insert is made in a mixed and separate way. In the first case, a single sewerage system was laid at the summer cottage, which unites the sewage systems from the bathhouse, house, storm drain. If such a union is not provided, for each type of collector, a separate tie-in is made into the citywide network passing along the street.

What way to drain water to choose

From the bath, water is supplied through pipes by pressure or non-pressure method.

The first type is a forced supply of effluents with a fecal pump. It is installed in the bathhouse or outside the building, for example, in a septic tank. This method reduces the amount of excavation required because there is no need to dig a trench to create a slope, and the risk of collector clogging is reduced.

In a gravity flow scheme, the drains move due to gravity, therefore, the calculation and arrangement of the slope of the pipes will be required. Elements of a larger diameter are used than with the pressure method, if possible, do not make turns. The advantage is independence from electricity supply and lower cost due to the absence of a pump.

Rules for arranging a drain pit

Before you build a drain pit for a bath with your own hands, it should be borne in mind that the cesspool can be airtight or allow moisture to pass into the soil. It all depends on the material of the walls and bottom.

Drain well options:

- Brick.The walls are mounted with red bricks, while they make continuous masonry or put stones at intervals. Use continuous concreting of the bottom or pour drainage.

- Made of concrete rings. More often, such a well is considered a relatively sealed option, since prefabricated elements are placed on a concreted bottom. But concrete walls in small quantities allow water to pass through if they are not isolated from moisture.

- From a plastic container. This model is sealed and accumulative, therefore it requires regular pumping of fluid.

Wells are made from car tires, which are placed one on top of the other.

Advantages and disadvantages

The sealed structure does not pollute the surrounding space, it can be used at any level of rising soil moisture during floods and rains. The permeable container allows you to save on pumping out wastewater, but the water goes underground and fills the surrounding soil. The lack of a drainage bottom is compensated by the remoteness of the pit from the house, dacha, well, vegetable garden and garden.

The downside of both systems is an unpleasant odor, which is removed by adding special chemicals to the pit. Brick pits are short-lived, gradually collapsing. Regular cleaning of sludge deposits on the drainage surface is required.

Construction technology

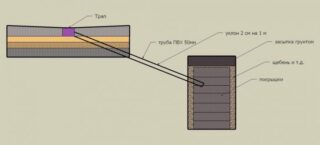

Prepare a site, dig a trench with a slope for the location of the collector to the site of the pit construction. The slope is made 2-3 cm per linear meter, the diameter of the pipe of the free-flow system is chosen 100-120 mm.

Further step-by-step instructions:

- dig a hole of the required size;

- at the bottom, a layer of crushed stone is poured with a thickness of 25 - 30 cm, or concrete is poured to a height of 10 - 15 cm;

- the walls of the pit are insulated from moisture and insulated;

- walls of ceramic bricks are laid on the mortar;

- the pipe is embedded in the masonry, the joint is insulated from moisture.

The edges of the pit are poured with soil, a cover is made of metal, wood on the top, a precast concrete with a hole is placed. The pipe is laid in a trench over a layer of rubble 5 - 7 cm thick.

Rules for arranging a drainage well

Structures are observation, water intake and filtration. The first and second varieties are sometimes combined, placed at the intersection of pipes or bends. They are cleaned from time to time, and if there is no further drainage, water is chosen. Such wells are used for the simplest drainage using an inclined clay castle and a receiving funnel.

Filtration wells for the device are not used to drain in the bath. More often, wells with a drainage bottom with a section of 1.0 x 1.0 m are provided. The depth of the pit is made below the freezing point of the earth or higher, but the walls are insulated with foam.

Pros and cons

For the arrangement, ready-made plastic containers, concrete rings of different diameters are used. The technology simplifies construction and speeds up the construction time. The advantage of piece designs is their low weight, the ability to install many inputs and outputs.

The installation of such a container can be done by the owner of the bath with his own hands, without the involvement of specialists. Plastic containers ensure environmental friendliness around, while there is the possibility of replacing and rearranging the barrel or individual pipes.

The disadvantage is that the finished containers are expensive.

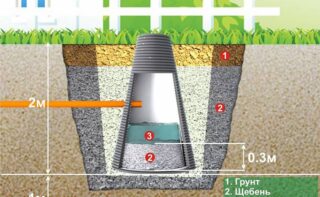

Self-construction of a drainage well

Dig a hole according to the dimensions of the future drainage device. The purchased pipe is cut with a grinder to the desired height.

Further guidance:

- 0.5 m recede from the top of the structure and a hole is cut out along the diameter of the inlet manifold, adding 1.0 cm for the seals;

- install rubber gaskets;

- the bottom of the well is poured with concrete to a thickness of 7-9 cm;

- the bottom of the plastic container is fixed with bitumen mastic;

- insert pipe bends.

The gap between the walls and the ground is filled with a mixture of gravel and sand. The top is covered with a hatch. Sometimes they purchase a ready-made plastic bottom so as not to concrete.

A septic tank as a drainage system

A septic tank is built not only for draining under a bath, usually waste from other plumbing devices goes into it.

Options for arranging a septic tank:

- Prefabricated reinforced concrete rings. They are quickly assembled, but require the involvement of a crane. There are elements in the form of a concrete barrel with a bottom for tightness, rings with perforated walls.

- Tanks with in-situ concrete walls. The option is much cheaper, but it takes a lot of time for the device, since you need to wait for the full cycle of concrete curing.

- Eurocubes made of plastic. A convenient and functional option, but expensive. It is installed without the involvement of special equipment.

Brick tanks require waterproofing of the walls, they are distinguished by increased labor costs.

Pros and cons

The septic tank is the most productive system for collecting and treating sewage water. After the third sedimentation tank, the liquid can be used for watering the garden, vegetable garden, and other household needs can be solved with its help. The degree of post-treatment depends on the type of decomposing agents used.

The disadvantage can be called the great labor intensity when installing several filtration chambers. At the same time, a significant area is required, which cannot always be allocated in a summer cottage or a small private plot. In this regard, the sanitary requirements for the arrangement of the septic tank are increasing in relation to waterproofing.

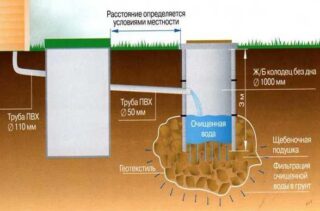

Construction technology

More often, a settler is made of two chambers, where large suspensions are deposited in the first, and filtration occurs in the second. They put the rings on the place laid for digging in, the distance between them is no more than 1.0 m. In the second ring, holes are drilled at least 50 mm in diameter for the drainage function.

Dig the soil inside the ring. As they deepen, they dig under the walls so that the element gradually sinks into the pit under the weight. The bottom is poured with concrete, the joints after hardening are treated with resin or ready-made bitumen mastic.

In the second ring at the bottom, instead of concrete, rubble is poured with a layer of 25 cm. Suitable pipes for the first container and between the wells are isolated from the cold. The top is closed with a lid with a hole.