Sectional doors are installed in private and industrial facilities. Designs are suitable for opening in a garage or in a fence at the entrance to the site. The canvas of the modernly designed passage organically complements the architectural style of the private mansion due to its attractive appearance. It is possible to install an overhead garage door with your own hands, since the installation is simple if you know the intricacies.

Advantages and disadvantages of a lifting structure

An optimally selected design effectively protects the garage from prying eyes, precipitation, and wind. Saves space in the room due to the fact that the sash rises and moves to the ceiling. Profitability is ensured by simple structure, few parts.

The advantages of sectional doors:

- impact strength and reliable protection against burglary, tightness;

- the material of the canvas is selected so that it does not collapse from weather conditions and other adverse effects;

- the gate can be installed in small areas;

- various stitching options are provided;

- there is a possibility of insulation with foam and polystyrene foam panels.

The mechanism is safe in operation. Mechanical and automatic control is provided. Manual lifting is possible if compensation springs are installed.

Only openings with right angles are suitable for installation. The span is reduced by 20 cm when the sash is open.

The principle of the overhead gate

The canvas consists of individual sections connected by hinges and installed in a frame. Guide runners are attached to the edges of the opening and on the ceiling for moving the segments. In the process of opening, the sections turn at an angle and go to the ceiling one after the other. The kit includes a spring-lever actuator or a counterweight system.

Types of overhead gates:

- Swivel. They belong to the category of simple structures, the structure has a sash, an engine, a steel frame. The door rises at a right angle, moves inward to the ceiling.

- Foldable. It tightly includes several sections with a width of 40 - 60 cm, when opened, the segments move along the guide runners.

- Rolled. The door is folded from thin aluminum slats. When opening, the canvas is wound with a rope on a drum attached to the ceiling. The compact structure is characterized by low burglar resistance.

The work is controlled manually or using an electric drive and a remote control. The blade is lifted by the levers at the bottom of the frame. The sections move by means of rollers at the ends of the sash frame. A gate with a simple drive opens by pulling the handle at the bottom of the leaf.

Materials for the manufacture of structures

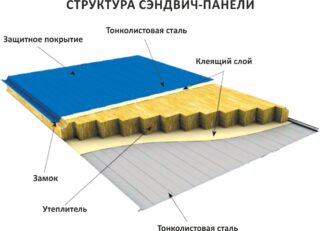

Materials are selected in accordance with the opening mechanism and the type of gate. If the door is folded from sandwich panels, they are joined so as not to roll one over the other to prevent freezing at the joints. A sandwich panel is a connected steel sheet, between which a heat insulator in the form of foamed polyurethane foam is reinforced.

The thickness of the elements ranges from 9 to 45 mm.Single slabs are produced without an insulating gasket, but they are not popular. Sandwich panels are made with a pattern that imitates corrugation, paneling, microwave; with a texture reminiscent of cherry, oak, birch, marble, orange peel.

For panoramic canvases, aluminum profiles with solid polycarbonate inserts with increased shockproof characteristics are used. In the overhead sectional doors to the garage, panoramic slabs are combined with the installation of sandwich slabs. Rolled aluminum and filling can be painted in different colors in accordance with the RAL catalog.

Sectional door design

Errors in the layout of the opening lead to the fact that it is almost impossible to install a sectional door into a decorated span. Side quarters next to the opening should not be less than 130 - 150 mm. If the left or right walls are less or absent, the installation of the guides occurs due to the entrance opening. The situation gives a decrease in the clearance by 10 - 20 cm on the sides.

The lintel should be left with a size of 300 to 500 mm, depending on the manufacturer of the structure. Increasing the height of the garage and lintel will increase the gate price and installation costs. The depth of the garage is calculated so that the door leaf and the operator can fit along the length. A side-by-side garage garage door requires a center wall design.

In the movement area on the ceiling, it is impossible to design lamps, other overhanging elements, also in the work area, doors and windows that open inward, and communication pipes are not planned. Welding is more commonly used to join metal parts. There are simpler ways, but you will have to make many holes, which will weaken the fixation.

Drawing of a lifting garage door

Additional tips when choosing the design and location of gates and mechanisms:

- The height of the opening is provided for at least 2.2 m, otherwise its operation will be inconvenient.

- During welding, a groove is left in the lower profile of the sash to attach a seal there.

- A canvas of such a design and materials is designed so that its weight does not exceed 100 kg.

- The self-drive for the lifting belt is made from a self-locking winch with a reversing mechanism.

- The remote control can be handled by the car alarm device if it is slightly altered.

The canvas provides for small inserts of light-transmitting or transparent materials in order to save electricity on lighting. There are locking elements to avoid pinching, to protect the structure from breaking.

Choice of automation

For manual opening, a spring-type device is provided, due to which the weight is compensated, and the force is measured in 10 - 20 kg (100 - 200 N).

Other types of coordination:

- Automatic control. The door is raised and lowered electrically. The device operates from a photocell, infrared or laser sensor, photo radar. An innovative method of video capture is applied, while the reader system recognizes the license plate and the biometrics of people.

- Remote coordination. The electric actuator is operated from a remote control, a button on a stationary remote control, a mobile phone (with a GSM module). If the device does not work or there is no electricity, unlocking is provided.

Internal unlocking is activated by pulling the cord fixed to the carriage, after which the gate operates in manual mode. Access to the cord appears when entering the room through an additional door. External release includes cylinder lock, key and cable. The constipation is installed in the body of the web, and the cable is brought to the lock and the carriage. Opening becomes possible after using the key.

Material selection

For the manufacture of the frame of the overhead gate with their own hands, they prepare wooden blocks of different sizes. You will need lumber with a cross section of 12 x 10 cm (box) and 10 x 10 cm (mounting on the ceiling).

Other materials:

- metal strip 40 mm wide, 2.5 - 3.0 mm thick;

- corners for the manufacture of a frame No. 3.5 with a wall of 4.0 mm;

- corners for guide runners No. 4, wall 5.0 mm;

- channel for bracket No. 8, thickness 5.0 mm;

- spring with an inner section of 3 cm;

- metal fittings with a diameter of 8 - 10 mm (for tension adjustment).

Guide strips are profiles that are attached to the opening with hangers. Distinguish between vertical and horizontal elements. The first type is used when the height of the garage and lintel is 2 or more times the size of the opening.

Spring mechanisms are used for balanced balancing of heavy door leaves that open upwards with their own hands. Use torsion arms and tension springs. The former are installed in industrial facilities, while the latter are used in private construction.

You will need a curtain material and an electric drive for automatic gate operation. For hand-made production, a wooden shield, trimmed with metal sheets or sandwich panels on top, is suitable. For thermal insulation, foam plastic, extruded polystyrene foam, an insulator in mats are used.

Material calculation and tool preparation

The calculation of metal profiles, material for the door and seals are made based on information from the drawing. The area of the sewing is calculated, the sheets are taken so that there is less waste. Steel parts can be welded together, so you should not be tied to the sales length of the profile.

Prepare tools for work:

- building or laser level, plumb line, corner at 90 °;

- hammer, pliers, screwdriver;

- tape measure, pencil, chalk;

- drill, screwdriver, grinder with a cutting wheel for wood and metal;

- welder;

- a set of wrenches, screwdriver, drills for metal, wood, concrete.

Missing tools can be rented for the duration of the work.

DIY installation

The finished frame is covered with a shield and finishing material. The base is made from a corner, while 2 holes are drilled in one profile shelf for attachment to the racks.

Next steps:

- Three holes are formed in the bottom shelf for fixing the spring and three more for fixing the channel bracket.

- The spring and the bracket are connected with an adjusting metal strip. A tension coordinator made of a steel rod is fixed to the bottom of the spring.

One side is made in the form of a ring, the second is threaded, the hinge assembly is formed using a corner with a hole. The device is welded in the middle of the frame between the bottom edge and the lifting arm. A plate with a hole for the coordinator is welded to the end of the arm. The rails are made from two corners so that the distance between opposite vertical shelves is 5 cm.

Operating tips

When lifting the canvas, the process is visually monitored so that there are no people and objects in the working area. It is forbidden to interfere with the movement of the sash, when lowering, be in the movement area. Do not give the remote control to children, let them open the garage door.

If damage to cables, parts, electrical cables is noticed, repairs are carried out with the help of specialists. The same applies to the appearance of pungent odors, unexpected noise. Entry and exit are allowed after a complete stop of the track in the boundary position.

You cannot change the gate scheme yourself and add structural details. Working units and friction parts must be regularly cleaned of debris and lubricated.