There are different versions of garage doors. They differ in their functioning mechanism and usability. Sometimes tenants prefer to invite a team of craftsmen, but it is not difficult to create a garage door with their own hands.

Types of structures

The earliest type of garage door is swing door. Even 30 years ago, this was the only option found in Russia. It was a massive structure with doors made of thick metal sheets. It is easy to do it yourself, while it is reliable, resistant to hacking and can serve for decades. Even in our time, deciding to install a garage door with your own hands, they often choose this option. However, in winter in snowy areas, the design will not be very convenient, since for the successful opening of the flaps, it will be necessary to first rake the snow.

More modern garage door options include:

- Constructions of horizontally installed sections connected by hinges. Elements of such gates are most often made of metal (thin galvanized steel or alloys with aluminum). In rare cases, wood is also used. When the gate is opened, it moves upward and locks itself to the ceiling. They help save space on the site, but they are not very resistant to burglaries.

- Lifting structure with hinge-link mechanism. It can be equipped with an automatic device or can only be opened manually. However, when using them, you must not park the car close to the gate.

- Rolling shutters, consisting of many thin slats. When opened, the web rises up and curls into a roller. In many ways, the mechanism of operation and features of use are similar to the previous version. They are suitable only for narrow (maximum 3 m) and low (up to 3.5 m) openings. They can be installed both on the inner wall of the garage and on the outer one.

- Sliding structure, which is a one-piece canvas, consisting of a metal frame and sheathing. When the gate moves, the rollers move them along the guide. It is a cheap and tamper-resistant design that is easy to automate.

When choosing a suitable option, the features of the layout of the space adjacent to the garage are taken into account - for example, the need to save space in the front or the lack of free passage next to the wall. The dimensions of the opening are also taken into account.

The frame of the structure is made of metal. It can be a professional pipe or a steel corner. For a solid sheet or a system consisting of wide sashes, corrugated board and sandwich panels are used. Sometimes this part of the gate is also made of wood. In such cases, a protective visor will be useful to protect the wood from precipitation. Narrow lamellas are made of sheet metal. The thinner these elements are, the faster the gate opens.

Required materials and tools

To make a garage door with your own hands, you need to prepare materials for the frame and canvas. The latter can be made from sandwich panels or thick sheet metal.The second option is distinguished by high strength, reliability and low weight, but the financial costs will be higher. Insulated panels weigh more, which can make it difficult to install the system yourself.

For work, you will need to prepare the following tools:

- puncher;

- welding machine;

- grinder for cutting metal;

- a brush or spray gun for decorating the canvas;

- measuring tools - construction tape, square and level.

The frame can be welded from a profile with a thickness of 50 mm. A corner is also suitable for this purpose. The thickness of the sheets for the web is selected depending on the permissible load. Usually 2-3 mm steel is used. The frame is made of 65 mm steel angle.

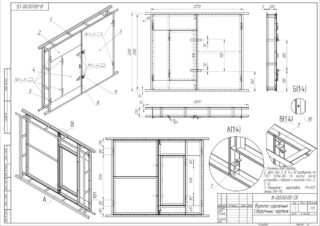

Schemes, drawings, calculations

In order for the structure to be reliable, it is recommended to create a sketch of the future gate before starting work. To do this, you can use existing schemes or design the system yourself. The drawing should reflect the dimensions of the main elements. A three-dimensional model of a structure can be prepared in a graphics program. In this case, the importance of calculating the supports for the frame must be taken into account. They must be strong enough to support the weight of the sliding flaps.

The dimensions of the doors depend on the dimensions of the car and the width of the garage. The distance from the frame to the car body must be made large enough (at least 0.3 m on each side), otherwise the vehicle may be damaged.

The standard door width is 2.5-3 m. The minimum distance from the frame to the perpendicular wall is 80 cm. The height of the structure for an ordinary car is 200-220 cm.

If it is decided to make a wicket on the sash, you need to determine its location in advance.

Production of swing gates for the garage

It will be problematic for one person, even with the necessary skills, to completely complete the work due to the large weight of some elements. Therefore, it is advisable to invite an assistant for installation.

Frame welding

To make a garage door with your own hands, you need to prepare the frame. They begin to do this only after the front wall has been erected. 8 elements are cut out of the corner, 4 of which correspond in length to the height of the opening, and the rest to the width. The outer and inner parts of the frame are formed from them. The elements are laid on a flat plane and the angles are measured. After making sure that all the parts have right angles, they are welded with seams. If in the process the straightness is broken, this is corrected by a lever made of scraps. If necessary, it is also possible to weld on additional corners. When the defects are eliminated, the frame is sanded.

Sash frame welding

The frame is made of metal profile pipes. When cutting, one should not forget about the need for a technological gap of 10-20 mm between the frame and the frame. It is needed so that the structure comes off freely. After checking the corners, they weld. To make the gate more reliable, stiffeners are installed in the frame in height. Two such elements are mounted in each sash. If the structure is long or heavy, the number of ribs increases.

Installation of metal sheets

The sheet for the first sash is cut out of such dimensions that it overlaps the second side by 20 mm. Then it is tacked to the frame. For the second sash, the sheet is cut out, taking into account the overlap. It should not reach the edge by 20 mm. So that the canvas does not lead, the sheets are point-welded. If continuous seams are applied, the frame tubes are fixed to the channel elements with clamps. Welding work is carried out alternately on both sides in fragments of 0.1 m.

Attaching the hinges

The lower part of the hinges is fixed to the supporting frame, the upper one - to the canvas. They can be made more reliable using internal attachments from thin reinforcement bars. The seams are cleaned. The most reliable lock for such gates is a lever lock.The use of a mortise model is also possible.

Painting

The doors are painted every 2 years in order to protect the door leaf from corrosion. The surface is degreased with a solvent, primed with a special compound and, after it has dried, covered with a coloring mixture. A roller or spray gun is suitable for this.

Replacement and maintenance of garage doors

The question of replacement usually arises in connection with a break in the structure or serious damage to the canvas. In the event of a break in the hinges or sagging, dismantling of the gate is not required. In the first case, it is enough to install new parts, in the second - to cut the lower areas of the sashes with a grinder.

For more serious problems, the canvas and fasteners are removed and replaced with a new structure.

To prevent sagging, do not leave the leaves open for a long time. If such a need arises, a support board is placed under each of them. Do not open the gate without the need. This will help extend their lifespan. If the system is equipped with automation, it should be regularly cleaned and diagnosed.