Many types of fences used in summer cottages and garden plots create an extensive shady space. This can impair the vital functions of plants, and also creates a favorable environment for pests. You can solve this problem by installing a netting gate. The latter consists of steel wire spirals screwed into each other by turns.

Advantages and disadvantages of netting gates

Do-it-yourself doors for a private house from a chain-link are easy to install. The process does not require complex skills, but it is advisable to involve one or two assistants to perform the work. Other pluses of this option:

- the site receives enough sunlight, which is important for the normal growth of horticultural crops;

- the design does not require staining or any special care;

- the fence can be decorated with climbing plants;

- the construction does not require large financial costs;

- resistance to destructive environmental factors.

The downside is the inability to hide the space from the views of outsiders. However, this can be achieved by decorating the fence with plants that intertwine it. Also, the mesh does not have sound insulation qualities.

What is the grid

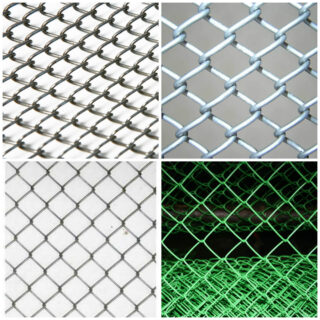

Chain-link gates are made of various types of steel wire. Non-galvanized mesh is made of ferrous metal and requires painting immediately after installation. With further use, the coloring composition will have to be applied every three years, otherwise the structure will begin to rust.

Galvanized mesh is especially popular with summer residents due to its unpretentiousness to the ambient temperature and the absence of a tendency to corrosion. It can be made by the electrolytic method (in this case, the zinc coating comes out thin) and hot. Sometimes the mesh is first welded and then covered with zinc. Such a product can be recognized by the absence of specks.

You can make a gate from a polymer-coated chain-link mesh. In terms of performance, this is the best option, but such a product costs more. Most often PVC is used for coating. The dimensions of the cells vary from 10x10 to 65x65 mm. The ends can be twisted or folded.

How to choose the right net for the goal

The performance of the chain-link is determined by the dimensions of the cells and the thickness of the wire. Products made from fine raw materials with large cells are the least reliable. It is also important to check whether the mass of the product differs from that specified in GOST. If the discrepancy is significant (5% or more), the mesh quality should be considered low.

The chain-link is sold twisted into rolls. Usually, the length of a product unit is 10 m, and the height is 150 cm. If you need a large mesh, you can place an individual order. When purchasing, you need to check that the edges do not part when you press on them. If a polymer coated product is selected, it should be assessed for scratches. If they are identified, this indicates low quality.

When choosing a cheap non-galvanized mesh, you should immediately purchase a special compound that protects against rust.

Manufacturing technology of gates from a chain-link

To find out how many support pillars are needed for the gate from the grid, you need to determine the dimensions of the sides of the perimeter of the site and divide each value by 2.5 m.If the quotient is obtained with the remainder, it is rounded towards a larger value and the supports are placed more tightly. Having prepared a drawing of the location of the pillars, they begin to mount the corner elements. Most often, the supports are made of metal. For lightweight mesh, use of wooden blocks is acceptable. The pillars can also be made of concrete - they are used for high-weight products. The supports are buried 1-1.5 m into the ground.

Frame materials

There are two options for mounting mesh gates. The budget method is tension: the product is attached to one post and unwound to the next one, pulled and fixed to it. Supports can be made of metal or wood.

Significantly more funds will be spent on the installation of a sectional structure. In this case, the chain-link is mounted in ready-made section frames.

How to pull the netting on the gate

The process begins by welding the hooks onto the pole. You can use simple screws or nails for this. In the future, a step-by-step guide for installing the mesh using the tension method looks like this:

- The product is pulled onto the supports. The roll is straightened and placed near the first post.

- The thick wire is threaded vertically into the first row of the web. The net is hung on hooks, and the cable is connected to the post by welding. This is necessary so that the canvas does not bend or sag.

- The roll is unwound to the next support. The wire is threaded through the initial cells and the web is stretched. Then the cable is threaded horizontally and welded to the post. The distance to the top and bottom edges should be 0.1-0.2 m.

- On subsequent supports, the canvas is mounted in the same way. It happens that at the end there is only 1 m of the net, and a longer length is required (for example, 2 m). Then a new roll is applied to the remaining fragment and a wire is woven between them. The result is a solid canvas.

When the net is fully stretched, the hooks will need to be folded. After that, if necessary, the canvas can be painted.

If a sectional design is chosen, the frames are boiled first. For this, a corner with parameters 40x5 or 30x4 mm is used. 15 mm is subtracted from the distance between the two pillars, and 10 cm from the height of the support. The first parameter indicates the length of the frame, the second - the width.

If the roll of the chain-link needs to be cut, this is done in advance. In this case, it is fastened in a similar way to the tensioning method. Rods are threaded into the cells from above and below the canvas, the canvas is pulled and welded to the horizontal corners. Metal strips with a cross section of 0.5 cm, a length of 0.2-0.3 m and a width of 5 cm are welded to the supports. The section is placed between the posts and connected to the strips.