A country house or suburban area cannot be imagined without a fence. It is not difficult to build a fence with your own hands if you follow the simple rules for structures made of different types of materials. For construction, improvised means are often used, which reduces construction costs.

Types of fences and requirements for them

There are several parameters by which fences are classified:

- functional purpose;

- location;

- material of manufacture.

There are special requirements for different types of structures.

Appointment

The functionality of fences can be very different:

- A decorative fence zones the site.

- If you install a fence in the garden, it will hide unsightly places - compost heaps or plowed land in the autumn-spring period.

- The continuous fence of the façade of the land plot protects from prying eyes and intruders, prevents the free entry of stray animals, and reduces the intensity of drafts.

- The fence on the border of the neighboring plot precisely defines the boundaries of the property, prevents the movement of domestic and farm animals.

Beautiful designs speak of the success and aesthetic taste of the property owner.

Location

The legislator has precisely defined the requirements for the enclosing structures facing the common space (street) and separating neighbors.

The height of the fence facing the street does not exceed 2.2 meters, but municipalities or horticultural societies can set different rules, raise or lower the maximum allowed height.

There are no restrictions on materials.

In any case, the fence between adjacent areas cannot exceed 1.5 m and must be transparent.

Material

For fences, a wide variety of building materials and leftovers from building a house are used:

- stone or brick;

- metal profiled sheet or siding;

- boards or picket fence made of wood;

- wave or flat asbestos slate;

- chain-link;

- welded 2D mesh;

- polycarbonate;

- non-traditional materials - transport pallets, PET bottles and other options, for which there are many interesting ideas.

When choosing a type, each of the classification points and the properties of a particular material are taken into account.

Fences made of wood

Working with wood products does not require a lot of experience.

Fences can be used for any purpose: for the outer perimeter of the site, at the border with neighbors and for decorative purposes.

Material advantages:

- low price;

- for construction, in most cases, hand tools are sufficient;

- variety of designs and designs;

- environmental friendliness;

- maintainability.

The cost of wood is influenced by the quality of the wood and the availability at the construction site.

A simple homemade fence can be built almost for free. Sawmills and woodworking workshops often distribute waste free of charge — trimmings, planks or slabs.

For installation, it is enough to dig in the supports from the timber, connect them with veins, to which the pickets are nailed.

If the developer is ready to invest money, there are several options for arranging the fence:

- fence with solid filling;

- picket fence made of factory material - the same geometric dimensions and planed;

- a wicker from a vine or an original version of boards;

- checkerboard - adjacent pickets are nailed from different sides with crossbars.

You can make a beautiful fence by placing the boards at any angle to the horizon, not just vertically.

The significant disadvantages of the tree are considered:

- relative fragility;

- loss of visual appeal without proper care;

- flammability;

- fragility.

Most of the shortcomings of wood are manifested when the installation and maintenance rules are not followed.

Construction features

The durability of timber structures is influenced by the ability to withstand wind loads and the resistance to rotting of parts installed in the ground.

It is possible to reduce negative factors by technological methods:

- the depth of embedment of the support into the ground should be from 80 cm for fences with a height of up to 1.5 meters and from 100 cm for fences above 2.0 m.

- mandatory processing of underground parts to prevent rotting or installation of thermowells.

To protect the tree, the entire part of the post and 20 cm below the ground level is first treated with open fire until a black surface is formed. They use gas burners, gasoline blowtorches. After that, it is enough to saturate the surface with antifungal compounds.

Another way is to treat the supports with resin or modern waterproofing compounds.

Special mounting sleeves made of plastic or wood significantly extend the service life of wooden posts.

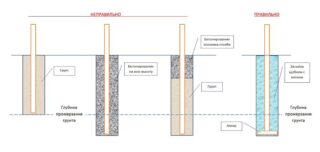

Installation of supports in the sleeve:

- The site is freed from weeds, the soil is leveled at the installation site of the fence.

- Dig holes 5–10 cm wider than the sleeve;

- Fitted sleeves made of plastic pipes, for example, sewer pipes for external work (orange). Another option: they hammer together a box from suitable pieces of boards. They must be treated with an antiseptic or tarred.

- Pillars are installed and fixed in an upright position with spacers.

- The sleeve is poured with concrete.

- Fall asleep and tamp the free space around the sleeve.

- They wait for the concrete to harden, usually 3-4 days are enough.

- Next, proceed to the installation of the veins.

The method of installing poles using sleeves is more time consuming and costly than installing supports directly into the pit and pouring concrete. However, it allows you to extend the service life of the fence by several years.

Pickets are nailed from the outside of the site - this will not allow unauthorized persons to use the logs to overcome the obstacle.

All components of the fence are treated with antiseptic compounds and painted. If this is not done, after one season of use, the wood will darken and lose its attractiveness.

Metal profile fence

A fence in the country can be quickly and easily equipped from a metal profile.

The material has a number of consumer and technical advantages:

- relatively low price;

- the speed of construction and ease of installation;

- versatility and practicality;

- with a service life of 15 years without corroded corrugated board;

- a rich selection of colors;

- an extensive range of types and sizes, which can be negotiated with the supplier;

- structural strength;

- corrosion resistance - sheets are galvanized or coated with polymer paints;

- soundproofing the site from street noise;

- fire safety.

The continuous cover has a high windage, which will require thorough preparation of the supporting structure. Incorrect installation causes deformation of the sheets, which deteriorates the appearance.

During operation, it is necessary to monitor the condition of the paint coating of poles and logs, which are most often made of black metal profiles.Corrosion and dripping drops of rust impair the appearance, the structure itself will last less.

Features of the arrangement

It is possible to make the fence strong and resistant to loads only with the correct installation of the pillars.

For supports, metal pipes of rectangular or circular cross-section are purchased.

It is better to choose a square profile with a side size of 40x40 mm. It is strong enough for a fence up to 1.5 m high.If the sheets are higher, pipes with a cross section of 60x60 mm are purchased.

Round-section supports are much more expensive due to the quality of the steel, but have no real advantages, welding of the log and supports in this case is technologically more difficult.

Before concreting, the pillars are treated with an anti-corrosion primer and painted in at least two layers. This is enough for the base to stand the entire cycle of using the profiled sheet.

The beds are fastened to the supports by welding, bolts through through holes or using special brackets.

The metal sheets are fixed with roofing screws, blind rivets, screws or bolts. The simplest technologically is the installation of roofing screws, which can have the color of the caps to match the color of the sheets.

When installing self-tapping screws under the cap, be sure to lay a damping washer made of rubber or silicone - this will prevent moisture from entering the hole and will not allow corrosion to form.

Fencing made of mesh-netting

It is customary to install the chain-link on the fences delimiting neighboring areas. A budget mesh fence for a private house has positive qualities:

- small windage;

- breathability, which eliminates air stagnation, which is harmful for planting of cultivated plants;

- light transmission, which is important for planting;

- low price;

- does not require maintenance;

- can be used as a support for climbing plants;

- easy installation.

Along with positive properties, transparency is the main disadvantage of the material. For external structures, the chain-link is rarely used - not everyone likes to be in sight of passers-by.

The netting is not an obstacle to the spread of weed seeds, which is an important function of the garden fences.

Features of the arrangement

Great attention is paid to the high-quality installation of support pillars.

The wind loads in the case of the chain-link are small, but when the mesh is stretched, great efforts are made to the supports, which can disturb the verticality of the installation. To avoid such consequences, the pillars are buried to a depth of 1 meter.

There are two ways to put a chain-link fence:

- Attach the mesh directly to the posts.

- Make frames from a metal corner, cover them with a chain-link, and then attach to the supports.

The second option is used when the decorative component is important. The fence will require periodic painting.

Slate for filling

Asbestos-cement slate is a popular material for fencing.

Advantages:

- durable;

- opaque;

- easy to install.

Slate also has disadvantages:

- high price, even in comparison with the professional sheet;

- fragility;

- unpresentable appearance.

The material is gradually becoming a thing of the past and is used, for example, if the roof covering is being removed and you need to build a fence in an inconspicuous place.

Installation is carried out by fastening with nails on wooden logs or bolts on metal ones.

It is customary to mount flat slate in frames made of a metal corner, which are then attached to the posts.

Euroshtaketnik

A particular case of using a metal profile is the installation of a fence made of euro-type shtaketnik. The material is made of a metal profile and painted with polymer paints.

The fence turns out:

- durable;

- outwardly attractive;

- translucent.

Among the disadvantages is the high price of components.

Original solutions

The desire to make a fence with your own hands from scrap materials gave rise to many options for the manufacture of economy structures.

Among the popular ideas, fences made of the following materials stand out:

- Shipping pallets available for free or for little money. The pallets are disassembled or assembled. Attached to pillars dug into the ground.

- Plastic bottles are a transparent but not strong material. Wind gusts create loud noise. The fence is easy for an intruder to cross. At the same time, the fence perfectly scares away birds that spoil the crop.

- Polycarbonate and forged metal look rich and beautiful, but at the same time, it is necessary to choose sheets with a thickness of at least 10 mm due to the fragility of the material.

- Gabions are nets filled with stones. The structure is heavy and will require a strong foundation. For the price, such a fence is superior to almost all other types.

- Cross-cut logs look unusual, but laborious to manufacture.

- Glass bottles filled with cement mortar.

You can build a fence in a private house or in the country from a variety of materials. The choice of design is made on the basis of the tasks to be solved, the availability of raw materials, skills in construction. A creative approach allows you to get unusual structures from what is at hand or left from the main construction site.