The design of the garage roof depends on the preferences of the owner, his financial capabilities, and the availability of available materials. Before construction, you need to draw up a project in order to calculate the amount of materials and assess the complexity of the work.

Features of roofs for a garage and their types

A garage does not need a special margin of safety and a high level of environmental friendliness of the materials used. It is necessary to determine:

- from what material the roof will be laid;

- the height of the roof above the ground;

- roofing area;

- climate features.

Next, you need to determine the actual load on the foundation, as well as the likelihood of a collapse or subsidence of the roof under the weight of precipitation.

Roof types

There are several types of roofs, which are based on simplicity and functionality. In the construction of garages, structures are most often found:

- flat;

- low-slope;

- steep slopes.

They are also classified by the number of stingrays. More often, when arranging garages, one- and two-slope options are used.

Material selection

The use of too expensive materials is impractical - the garage is rarely the main building on the site.

For external coating, they are often used:

- corrugated board;

- slate;

- ondulin;

- roofing material.

Translucent polycarbonate is often used as a roofing material.

Tilt angle

Any roof must have an angle of inclination. For flat roofs, it is several degrees. The slope of the pitched roof depends on various factors, but the location on the windward side is fundamental. This rule is respected even when the garage is closed from the wind by other structures.

Shed roofs

Simple and reliable roofs with one slope are often built over utility structures, which include garages.

Shed roofs owe their popularity to a large number of advantages:

- simplicity of design;

- long service life;

- profitability.

A pitched roof is formed using separately installed rafters resting on walls of different heights. The role of walls can be played by individual elements of frame structures (pillars, columns, etc.)

A well-built single-slope design provides excellent ventilation, which eliminates the formation of condensation, which prevents excessive moisture and decay of the wooden components.

When constructing pitched roofs, relatively few materials are required, which makes its design attractive when arranging garages.

A relative disadvantage that is inherent in lean-to roofs is the inconvenience in arranging an additional space (attic) for storing various materials and devices. However, it can be easily eliminated if you build a small workshop above the garage. In this case, it is recommended to use a semi-attic scheme, which will allow you to get a two-story garage at low cost.

Garage roof design

The main feature of a roof with one slope is the presence of support under the edges of the rafter legs. In this design, the rafters are ordinary beams, laid at a slight angle, allowing free precipitation to be removed at any time of the year.

The slope of a pitched roof seems to be one of the most important parameters of a garage. Thanks to him, it is determined whether walls of different heights are needed or it will be enough to install a cantilever-running frame on one side.

When determining the angle of inclination of the slope, one must take into account the climatic conditions of a particular region and the type of roofing.

- It is irrational to equip single-slope structures with a slope of the order of 5-7 ° in regions with heavy snowfalls. However, they performed well in areas with little snowfall and high wind activity. At the same time, single-slope options with an angle of inclination from 20 to 25 ° are not recommended to be erected above free-standing garages.

- When equipping flat roofs up to 8 °, roll roofing materials are used - polymer or multilayer bitumen-polymer and bituminous materials. An angle of inclination of up to 10 ° will require laying of bitumen-polymer materials in 2 layers. If the slope of a pitched roof is between 15 and 20 °, it is better to use flat or corrugated slate as the roofing material. For a single-slope version with a slope of 25 °, corrugated board or metal tiles are used.

The total area of the slope is of no small importance. When calculating it, the dimensions of the overhangs are also taken into account, which should effectively protect the structural elements from direct and oblique rain. Overhangs should be:

- 30-40 cm above brick and concrete walls;

- 10–20 cm above metal sheathed frames;

- 50-60 cm above the log cabins.

Sometimes the size of the overhangs is increased. In this case, they are supported on additional pillars installed on a foundation common with the garage. It is possible to arrange a separate foundation for them.

Structural complexity of the rafter system

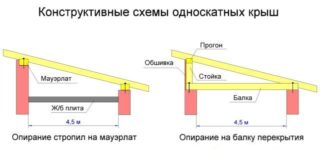

- If the span does not exceed 4.5 m, the structure of the rafter frame includes parallel-laid rafter legs, which are connected to the Mauerlat or elements that replace it.

- If the span is between 4.6 and 6 m, the rafters may sag due to the long length. To avoid this, it is necessary to strengthen the structure with struts.

- If the span exceeds 6 m, it is conventionally divided into sections, between which a purlin structure with vertical supports is installed. The running frame is supported on its own support, which looks like an inner wall.

As a rule, the interior space of the garage measuring 3.5x5.2 m is considered optimal for one car. At the same time, it is possible to build a rafter system according to simplified schemes.

When the slope is sloped across long walls, the rafters can be laid without additional struts, and if the slope is along long walls, the rafters will have to be supported with struts.

It is better to develop two types of a pitched roof, which will allow in the future to choose a more technologically advanced and economically viable option.

Calculation features

The calculation of the elements of the rafter frame for a pitched roof begins after the completion of work to determine the geometric parameters. Calculations are carried out using special computer programs, for the launch of which it is necessary to prepare a number of initial data, for example, mass per 1 sq. M. roofing, continuous lathing (when installing slopes with an angle of inclination up to 25 °), insulation (if necessary).

You will also need to find out the average mass of snow cover, typical for a particular region (SP 131.13330.2012).

Shed roof installation

First, a frame is assembled, which is attached to the Mauerlat. After that, a crate is stuffed onto the frame and heat and waterproofing materials are sequentially laid. Then they start laying the finishing layer.

For those who first decided to make a roof on the garage on their own, it is recommended to use corrugated board as a topcoat.When working with this material, you do not need to use a special tool, and the weight of each individual sheet will allow you to do the job without helpers. The corrugated roof does not require any additional processing.