Almost every homeowner can build a cozy garage for his personal car on his land plot. The emergence of new technologies and building materials will easily allow the owner to build a budget garage with his own hands.

Types of building materials

The choice of materials for the construction of a garage is carried out taking into account financial capabilities, aesthetic preferences, make and model of the car.

Most often, for the construction of a garage they use:

- sandwich panels;

- foam, slag and expanded clay blocks;

- brick;

- corrugated board.

Each of these materials has advantages and disadvantages.

Brick

Brick is a traditional building material from which capital structures for various purposes have been erected for a long time. The garage will be no exception, especially if you need to equip a storage space for a car and an inspection pit, a cellar, a workshop, as well as an additional rest room on the 2nd floor.

Brick garages are characterized by strength, reliability and durability.

Brick walls:

- do not burn, which is important for rooms where fuels and lubricants are stored;

- allow you to mount electrical wiring, supply water, and, if necessary, gas;

- provide reliable protection against intruders.

Brick is environmentally friendly and in many cases does not require decorative finishes inside and outside the garage.

The disadvantages of bricks include:

- complex and lengthy masonry process;

- the need to build a solid foundation and thick enough walls, which is required for a comfortable stay inside the garage in summer and winter.

Garages are usually built from ceramic or silicate bricks. The latter is more common - it is cheaper and has good performance characteristics.

Gas-filled blocks

Gas blocks are made on the basis of concrete. They belong to the class of cellular concrete - there are air bubbles in their structure. The technologies for the production of aerated concrete and aerated concrete are different, but the characteristics are identical. The difference lies in the fact that aerated concrete is cut after making a large slab, and aerated concrete blocks are poured into ready-made forms. Therefore, the latter have closed pores and are less hygroscopic.

Gas-filled blocks provide:

- good thermal insulation properties:

- high masonry speed.

Aerated concrete blocks do not burn and are characterized by high frost resistance, strength, and vapor permeability.

Compared to brick, foam and gas blocks are distinguished by their low price and low weight. Buildings do not require a strong foundation.

Disadvantages:

- walls need external finishing;

- special fasteners are required for mounting wall cabinets, shelves, etc.

When laying walls from gas blocks, strict adherence to technology is necessary, otherwise cracks may appear.

Slag and expanded clay blocks

Slag and expanded clay blocks are made on the basis of a traditional mixture of cement, sand and water, to which a filler of slag (sawdust, crushed stone, etc.) or expanded clay (granules ranging in size from 5 to 40 mm) is added.

Both of these blocks are lightweight and large in size, which makes it possible to erect walls on a lightweight foundation.They have the same advantages as aerated concrete blocks, but they have different disadvantages.

Cons of cinder blocks:

- low thermal insulation properties;

- high hygroscopicity;

- unsatisfactory appearance, requiring external finishing of the building.

Disadvantages of expanded clay blocks:

- difficulties in processing - they can only be sawed with a saw with victorious teeth;

- for fixing wall cabinets and shelves, anchor bolts and dowels must be used.

The use of expanded clay blocks in construction requires the laying of more powerful foundations.

Both types of blocks have an unpresentable appearance and require additional wall finishing.

Sandwich panels

Sandwich panels are ideal for building a warm garage. Structurally, the material is a multi-layer plate consisting of a layer of insulation, covered on both sides with metal, plasterboard, etc. As insulation, polyurethane foam, mineral wool, etc. are used. not afraid of moisture and is distinguished by the ability to self-extinguish), which is protected by metal panels.

Benefits:

- ease of installation and high speed of construction;

- low cost;

- for the construction of walls, a lightweight foundation is sufficient;

- the possibility of dismantling the structure and transferring it to another place;

- does not require additional external finishing.

Disadvantages:

- insufficient wind resistance;

- the need to comply with the installation technology;

- deformation when exposed to direct sunlight;

In a sandwich panel garage, all equipment must be anchored to the floor.

Professional list

Profiled steel sheets with protective and decorative coatings do not require foundation laying. Among the disadvantages of this material are noted:

- low thermal insulation;

- insufficient level of security - the sheet is easy to cut from the outside;

- low mechanical strength, which over time leads to a deterioration in appearance (dents, scratches, etc.).

A garage made of a profiled sheet will cost many times less than from other materials. However, when trying to save money, you will have to sacrifice the reliability, safety and ultimately the safety of the car.

Garage layout

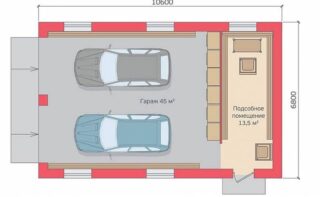

The preliminary planning of a budget garage is carried out based on the requirements of the current building codes (DBN V 2.3-1: 2007), which regulate its minimum size. According to this document, one parking space must occupy at least 5.0 m in length, 2.3 m in width and 2.2 m in height. In addition, it is necessary to arrange protective zones on the side and end sides of the vehicle. Their width should be at least 0.5 m.

When developing a garage project, take into account:

- driving experience of all family members who have the right to drive a car;

- the physical health of all drivers;

- the growth of all family members who can enter the garage.

The garage will be comfortable if its height is 40 cm or more above the head of the tallest member of the family. In any case, the internal dimensions are chosen based on the real needs of the car owner and his family members.

- If it is necessary to ensure the passage of a baby carriage, the distance from the garage wall to the sides of the vehicle must be at least 1.1 m.

- If you need to install a washbasin in the garage or provide a place to store bicycles on the wall, you will have to create a free area of about 1.5 m around the car.

If it is supposed to carry out maintenance and repair of the car in the garage, the placement of lighting devices is important, for example, above the engine compartment of the car, workbench and tool storage. Provide places for installing the required number of sockets for connecting power tools, heaters (if necessary), etc.It is also advisable to conduct a three-phase electrical network to the garage.

All outlets must be equipped with protective features capable of preventing electric shock to persons.

Basic construction works

The beginning of construction work during the construction of the garage is preceded by the clearing of the territory and the choice of the place where the building will be located. There should be no utilities in this place. It is important to provide space for opening the garage door and leaving the car.

The selected place is marked out according to the project. If an inspection pit is provided in the garage, it is dug out in the center of the site.

Next, they mark and dig trenches for laying the foundation. Their width is at least 40 cm, and their depth is 60-100 cm. Then large crushed stone or stones are laid in rows and each row is poured with a cement-sand mixture. If necessary, the entire area of the future garage is poured with concrete.

After the building mixture has solidified, they begin to erect walls, combining it with the installation of garage doors. This will allow the gate to be securely fastened to the walls.

When erecting walls and installing gates, you need to constantly monitor their verticality.

The construction is completed with the installation of the roof and finishing of the internal and external surfaces of the garage. The type of roof, the materials for its arrangement, as well as the methods of wall decoration completely depend on the preferences of the car owner.