Facade siding for exterior decoration of the house protects the walls from snow, rain, wind and decorates the building. In the course of production, the extrusion method of forcing the raw mass is used, then the outgoing plates are cut to the required size. The final facing material is formed in co-extruders, where two layers of vinyl tape are connected at the molecular level.

What is the basis of facade siding

The inner layer of polyvinyl chloride makes up 80% of the siding; additives are included in the mixture to improve the performance. Stabilizers, modifiers, dyes impart color, shine, resistance to atmospheric influences, increase flexibility, and extend the service life.

The basis of the facade cladding includes substances:

- titanium dioxide (dioxide) fixes the coloring pigment, stabilizes the structural structure;

- calcium carbonate (carbonate) is presented as a filler;

- butadiene increases resistance to wear, prolongs the service life;

- concentrated pigments add shades;

- lubricants contribute to the appearance of a smooth surface, prevent the strip from sticking.

The inner layer of the facade siding retains the strength and geometric dimensions of the strip. The outer coating protects the panel from UV rays, frost, moisture, it takes up 20% of the total volume of the product.

The main consumer properties of siding

There is a siding on the market with a visual imitation of various materials on the front surface in accordance with consumer needs. Ease of use, compliance with safety requirements, reliability, determine the popularity of the material for wall decoration outside.

Siding has valuable consumer characteristics:

- effectively protects vertical fences;

- performs a decorative function;

- matches with stone, wood, synthetic sheathing;

- does not rot, resists moisture, microorganisms, fungi do not multiply on the surface, rodents do not live inside the frame;

- belongs to the category of environmentally friendly materials, does not emit harmful components into the air.

Ease of maintenance and repair lies in the fact that the surface of the wall siding can be washed with clean water from a hose, and in case of severe contamination, use standard detergents. To replace the damaged strip, the casing can be disassembled and reassembled.

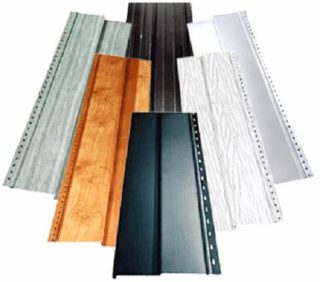

Types of facade siding

The popular material is produced on a variety of substrates to meet the demands of simple and demanding applications. For installation, standard initial and final strips are provided, window moldings and profiles for edging doorways are used.

On the inner and outer corners, special decorative and structural elements are placed that cover the ends of ordinary stripes. The siding is simply snapped into place, due to the structural strips along the entire length of the strip, they are fastened with self-tapping screws to a wooden or metal frame.

Aluminum

Features of Aluminum Facade Siding:

- resistant to sudden changes in air temperature, does not burn;

- retains color in the sun all the time of operation;

- can be used in conditions of high atmospheric humidity.

The disadvantages of aluminum are that the strips are devoid of plasticity, so a special technology is required to take into account the expansion and contraction during heating and cooling. Careless transportation may cause the material to crack.

Vinyl

Siding is mounted:

- vertical stripes;

- horizontal.

The first type of installation is rarely used, more often they place widespread horizontal panels like "herringbone", "ship board". A variety is used that imitates convex "logs" and cladding with a wooden "block house". In this case, the surface film is made with a corresponding pattern of certain rocks. Stands with imitation of a wooden log house are placed as corner elements.

Steel

Steel panels are made of profiled cold-rolled and hot-dip galvanized metal coated on one or two sides. The strips are connected using a perforated edge (expansion compensation) and a lock. The material is attached to the frame through the slots in the working part of the lamellas.

Steel siding is heavy, the surface gets dents after impacts that cannot be repaired.

Wood

Processing is carried out:

- drying wood to 15 - 18% moisture, use resistant larch and tropical species merbau, teak, iroko;

- heat treatment at +175 - + 220 ° C and high humidity, which increases the resistance of the raw material against decay, use ash, pine;

- by impregnation method - impregnation with antiseptics under high pressure.

There are groove-comb joints (various types of block house, lining), as well as joining in a quarter, along the section in the section. There is a combination of overlap, which provides for rectangular boards or wedge-shaped elements, as well as a butt joint. The latter type provides for a straight joint, beveled and with a groove.

Cement

Fiber cement siding for walls has a long service life of up to 50 years. They put finishing on objects for various purposes, they are used in any climatic zones. Fiber cement panels do not rust, retain their shape in hot weather, the color remains constant, since pigments are introduced into the mass during the production process.

The disadvantage of cement slabs is that the square of the material weighs 6 - 15 kg, depending on the thickness, therefore, reinforcement of the supporting frame for the material is required.

The benefits of siding

Useful qualities are manifested in the fact that the user can choose from a wide variety of materials on the market. Old buildings are transformed after the installation of panels, they take the form of a wooden hut, a stone structure or a house with a brick facade.

The durable material pleases the eye with the perfection of its forms, it stands for a long time without losing the properties declared by the manufacturer. Such panels are characterized by a reasonable ratio of cost and quality. Installation is not difficult, does not require special skills. The main thing is to understand the technology of installing a metal profile, fixing insulation and waterproofing. The strips are connected without difficulty, since the manufacturers have provided the necessary parts, slots and locks for ease of use.

Main characteristics

The metal frame is made of profiles:

- run CD-60;

- profile for strapping UD-25;

- mounting bracket ES in lengths of 90, 120, 160 mm.

The panels are admitted in lengths of 3.0, 3.66, 3.76 m, while the width varies within 17 - 25 cm, depending on the type. The strips are 1 - 1.2 mm thick.

Installation features

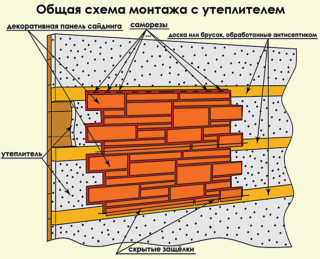

Before finishing, gutters, pipes, lamps are removed from the facade, after work they are put back. Wooden slats are treated with antiseptics or hot drying oil from decay and to increase moisture resistance.

Insulation is placed on the facade between the vertical elements of the frame. It is protected with a film so that a ventilated gap 2 - 3 cm thick is formed between the materials. There should be no holes or holes in the insulating layers.

Siding is cut with a hacksaw, iron scissors, jigsaw, grinder. The strips are attached to the profile with self-tapping screws, preferably with a galvanized coating so that the hardware is located in the center of the mounting slot.

Facade siding manufacturers

Domestic manufacturer Alpha Profile has been working in the Moscow region since 1995. It manufactures products of the brands "Prestige", "Acryl", "Alta-siding" in light green, lemon, strawberry and beige colors, and the component trims are in brown and white colors. Finishing is financially available to all buyers and lasts up to 50 years.

Canadian manufacturer Mitten has been producing vinyl products for 60 years, workshops are located in many European countries. Famous brands are Sentry and Oregon Pride. The panels are placed even in frosty weather, thanks to a specially designed slot system. The strips are 1.2 mm thick.

European production introduces acrylic and vinyl products to the market Tecos, in the Russian space, siding of this brand has existed for about 15 years. A characteristic difference is the multiple imitation of materials and the shape of the lamellas, which creates an attractive appearance.

USA company Gentek is engaged in aluminum siding and produces competitive quality products at an affordable price. The brand produces unique siding designs with a wide variety of design options.

Manufacturer Alkoa works with metal siding, which has been sold in Russia for 24 years. A polymer layer is used as a coating, which has a 50-year guarantee and is called Alumalur 2000. The protective film has many colors and shades, presented in the form of natural stone, various types of expensive wood.