Natural finishing materials are always popular, solid wood and parquet floors are no exception. This type of coverage needs regular renovation. Real estate owners have to sand wood floors during the construction of a building and at various stages of its operation. Sanding is used to prepare new flooring for finishing, leveling and renewing the old one.

The difference between grinding and scraping

In order to save money on hiring hired workers, many owners of houses, dachas and apartments decide to polish the wooden floor with their own hands. At the planning stage, there may be confusion associated with the concepts of "scraping" and "sanding" of the floorboard. Here you need to figure it out to the smallest detail, since for each technology you need to purchase different tools, materials and equipment.

Sanding is the removal of the top layer of material. The purpose of this event is to remove old paint, eliminate large irregularities and drops, refresh the surface, seal cracks and holes. This is one of the preparatory stages of the restoration of the coating, implying its rough processing.

Grinding of plank floors and parquet involves the elimination of minor defects left after rough leveling, the creation of a perfectly flat surface, bringing it to gloss, emphasizing the natural beauty of wood. The process is subtle, delicate, almost gem-quality.

Grinding methods

In order to qualitatively polish the wooden floor from the boards in the country with their own hands, the owners can opt for the following methods:

- Manual. It does not involve large financial expenses, but it requires a lot of time and the application of considerable physical effort. Suitable for processing small areas with cycles, float and emery paper.

- Machine. This approach is much more productive, faster, but you have to fork out for the purchase or rental of special equipment. Sanding a wooden floor with a sander allows you to achieve excellent results in a short time and without much stress.

The decision is made on the basis of an analysis of the condition of the flooring, its area, own physical abilities, financial capabilities and the timing of the repair.

Types of grinders

For sanding a tongue-and-groove floor, you can buy or rent this type of machine:

- Drum. Powerful aggregates that can be used at all stages of processing. It is done by cutting the abrasive onto a thick, fast-rotating shaft.

- Tape. Stitching takes place by a strip rotating between two rollers. Its length and width differ for different brands of machines.

- Disk. Designed for surface finishing. The working tool consists of one static or three movable discs rotating around a common axis.

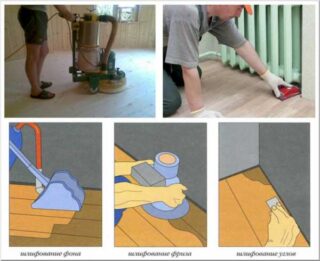

- Borderny. Designed for effective leveling and polishing of areas of the coating along the walls inaccessible to the above technique.

- Corner. They are subdivided into disc (grinders) and vibrating (boots). Used to access corners, under batteries and other places where manual and other mechanical methods are impossible.

To sand wood with a minimum amount of dust in the room, you should take equipment with the function of connecting an industrial vacuum cleaner. In this case, the work will be done efficiently, quickly and cleanly.

Tool selection rules

When choosing devices for processing flooring, you should adhere to the following criteria:

- conformity of the type of equipment to the specifics of the tasks assigned;

- functionality required for polishing in all areas of the room;

- high power and performance;

- the presence of adjustments for the level of lowering the abrasive and the pressure on the floor;

- simplicity and clarity of management, so that you can do the job yourself without complications.

The higher the price of the item or its rental, the better the tool will sand.

Preparatory work

The processing of the wood flooring is carried out after the preparatory cycle.

It includes the following steps:

- Removal of furniture and other interior items from the room.

- Dismantling of skirting boards.

- Removing linoleum or carpet.

- Checking the flatness of the surface. The hardware sticking out above it is deepened or pulled out.

- Scraping to remove all irregularities.

- Puttying the remaining recesses with transparent putty, filling the cracks.

- Leveling the repaired areas.

In conclusion, you need to clean the work area of debris and seal the doorways hermetically.

Do-it-yourself wood floor sanding

The work should be carried out according to the following method:

- Fill the equipment with a coarse abrasive appropriate for the unevenness of the wood.

- Perform initial penetration by moving the tool diagonally to the surface.

- Subsequent passes should be done with the replacement of the abrasive after each time in the order of 40-60-80-120. The first two times move the device across the boards, and the last two along. Stopping and starting the tool motor can only be done after it has been lifted off the surface. The reverse leaves marks that are difficult to remove.

- Finishing polishing. It is carried out with particular care with a nozzle with the finest grain. Strong pressure should be avoided so as not to leave dents.

- After the end of the last phase, dust is removed from the coating and the quality of the work performed is checked.

You need to change the nozzles without waiting for their complete wear. Otherwise, the machining efficiency will drop dramatically and the tool will overheat.