After heavy snowfalls, avalanches roll down from the rooftops and cause danger to humans, as well as spoil the structures on which they fall. To reduce the risk, snow guards are installed on the roof in most houses of different storeys. Universal technical devices are mounted during the construction of the roof or after the completion of the roofing, while choosing the optimal type of protective element, taking into account various influencing factors.

The need for a snow guard on the roof

Snow on the roof is compacted, its weight in some cases reaches a centner and more, so it is important to prevent a sudden loss of mass during warming. On steep roof slopes, it is inconvenient to clean the cover by hand, therefore it is necessary to install snow-holding devices for the roof.

The idea is that when solid precipitation accumulates, an avalanche begins to slide down the tiles or corrugated board under the influence of its own gravity, and obstacles in the way keep the cap on the roof. At the same time, the mass gradually thaws and decreases in volume, the risk of injury for random people is reduced.

The installation of the holder has the purpose of:

- ensure the gradual melting of snow;

- prevent the breakdown of the drainage system;

- to reduce the risk of destruction of the supporting frame with sudden release from a large mass;

- to protect people when cleaning the roof area from snow;

- save the owner's time so that he does not have to remove ice and a packed pile of snow.

Snow serves as a means of additional insulation of the roofing area. Snow stopping devices distribute the load from precipitation evenly over the surface.

Varieties of designs

Retarding models are divided into structures that dosed the mass through themselves and those that create impenetrable barriers. A phased passage of snow causes a decrease in the kinetic energy of the descending mass from a critical level to an acceptable and safe one. The barriers keep snow out and it will gradually melt without causing harm, provided the flexible roof or profile metal cover is properly waterproofed.

Dosed permeable snow catchers on the roof are divided into several varieties:

- tubular holders for smooth convergence;

- lattice types;

- bows (teeth) mainly for flexible cover.

The obstacle at intervals forms a passable barrier, under its own weight the snow is pressed into the tubes or between the vertical posts of the grating. The crumbling parts enter the drainage system and do no harm.

Completely blocking installations are:

- corner or lamellar;

- snow logs.

They put barriers around the perimeter, not far from the bottom at the level of a vertical projection of the wall of the house. The holders must be fastened above the area where the rafter rests on the wall. The installation method is determined according to the installation instructions for a specific type of roof.

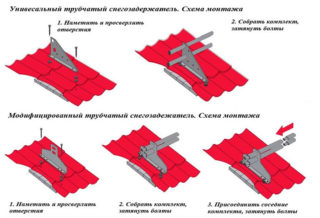

Tubular

The device consists of vertically positioned brackets, the holes of which are used for fastening horizontal sections with pipes with a transverse size of 10 - 30 mm.The tubular snow holder must be installed along the bottom of the slopes, its parts are made of metal and treated with resistant paint to match the roofing material.

Requirements are imposed on tubular types:

- withstand the weight of the calculated load;

- have rigidity and strength;

- not destroyed by moisture.

Tubular retainers are produced in various versions depending on the type of coating (metal, profiled sheet, ceramics). For copper sheets, snow guards are made of a similar material. An oval is considered the optimal shape of the through-hole - this is how the installation effectively resists the load and does not experience destructive deformations.

Lattice

The barriers are a lattice oriented horizontally like a parapet. The device has vertical rods, the sizes between them vary from 5 to 20 cm. Mounting of snow guards on metal tiles is done using brackets, they are attached to any type of roof.

Powerful supports are fixed with self-tapping screws for the roof, while driving them into the body under the roof load-bearing elements. The lattice length is 1 - 3 meters, respectively, 2 - 4 brackets are taken. If necessary, the length of the grates is shortened to the desired size. The universal types have a flat footprint, so they can be easily mounted on surfaces with different characteristics, such as wavy or flat.

Lattice models are used not only for their intended purpose, but also as roofing systems. More often, such elements are used on gable, hip structures with a slope of more than 20 °.

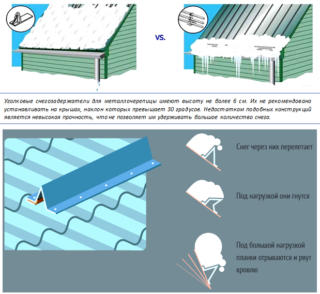

Corner and lamellar

These types are used for low snow loads, mounted on structures with a slight slope of the slope. The corner snow retainer (the second name is plate) is represented by a metal rolling profile of the corresponding section. In the lower shelf, holes are provided for fixing to the surface using self-tapping screws 50 - 80 mm long (attached to the crest of the wave, through a wooden base).

Mounting parameters:

- the average height of the corner element is 60 - 100 mm, and the length varies between 200 - 300 cm;

- the intervals between the rows are made 0.5 - 1.0 m;

- for a roof slope up to four meters long, 2 tiers are set, with a length of more than 6 meters, 3 - 4 rows are installed.

Protective elements are placed above the load-bearing wall, in the place of maximum punching shear strength of the roof. The upper edge of the corner is always set so that it is at an angle of 90 ° to the plane of the roof, the length of the corner is chosen by calculation.

Bugels

They are called teeth, point and hook snow holders for soft roofs. The design and small dimensions in length do not allow withstanding heavy loads and large volumes of snow. Sometimes the devices are installed in combination with tubular or lattice types, and separately they are used only for roofs with flexible roofing.

The single element is represented by a triangular design with a fixing plate. Such installations do not prevent the fall of the snow mass, but compensate for part of the effort during an avalanche. The yoke stops are evenly distributed over the coverage area, and the placement scheme is applied individually, depending on the slope and design of the slopes.

When fastening to corrugated materials, a support rail is installed on the crate, which is placed in a raised wave along the height of the profile bend. It is better to do the installation at the same time as the roofing device.

Wood log

Initially, such a snow retention on the roof was used on slopes with small slopes, then the type gained popularity, and it began to be mounted on roofs of various steepness. The element is a round log with a diameter of 120 - 150 mm and a length of 3 m.The obstacle is held on two fasteners, often does not support the weight of the icy mass of snow and falls.

Such barriers are relevant for wooden roofs and shingles. The disadvantage is that in the gap between the roof and the log (2 - 3 cm), snow is clogged, which did not have time to go down under its own weight. Under the influence of drops, it melts and freezes, and several such cycles lead to the accumulation of layers and an overload of the element.

Logs are made from a hollow pipe, which is stylized as a tree log to match the roof. Massive wood structures are fixed to the rafters with long screws or studs with nuts.

Installing snow guards on the roof

Protective elements are best installed during roofing. Reliable shock-absorbing pads are used to preserve the integrity of the waterproofing membrane. The step and gaps between the elements during the installation of snow guards are taken by calculation, depending on the slope of the roof and the material of the covering.

Tools for assembling a set of elements for a snow retention system;

- screwdriver with nozzles, drills for metal;

- wrenches in a set;

- building level, lace;

- measuring tool (square, tape measure);

- electric jigsaw, scissors for iron, hacksaw with a blade for metal.

Each type of installation has its own peculiarities, the system is installed over the entire roof or only over certain places, for example, balconies, building entrances, parking lots, and pedestrian paths.

From metal tiles

Slat barriers are supplied with a steel support to reinforce the structure. Tubular breaks often occur as the mounting brackets were poorly fixed to the rafters or grating. Inefficient operation of the delay system is sometimes associated with errors at the design stage. The elements do not trap snow if they are placed too rarely on the roof made of metal tiles or if the number of tiers is changed downward.

From corrugated board

Other reasons for separation from the surface of the corrugated board:

- the brackets were fixed in the eaves area and not over the wall;

- insufficient number of supports;

- incorrect counting of the number of rows;

- large horizontal gaps between the snow holders.

The brackets are placed on the corrugated sheet using rubber gaskets. During installation, they try not to squeeze the shock absorbers of the self-tapping screws in order to maintain tightness. Additionally, the places of fixation are treated with sealants for outdoor use with anti-frost and moisture-resistant characteristics.

When installing tubular holders, the extreme tube is removed by 15 cm, a smaller distance increases the load on the extreme support and can lead to a breakdown.

For standing seam roofs

The coating material is galvanized, ordinary iron, copper or aluminum, steel with a polymer coating. Smooth surfaces do not trap snow, so the risk of avalanches is increased. On a seam roof, snow protection structures are not installed in a standard way, which provides for fastening through the covering material to the supporting elements.

Snow holders are mounted on the details of the edges (protruding joints). The brackets are placed on a rebate, secured with clamps and lattice or tubular types of barriers are installed. There is no need to install additional parts to strengthen the structure of the rafters or lathing, the integrity of the roofing material is not violated.A seam roof supplier sells brackets and snow guard systems with the product, or you can purchase standard fastener parts separately from the store.

For soft roofs

Toothed elements or yokes are intended for surfaces with a rough surface, which themselves trap solid deposits. The same materials include euroruberoid with dressing, bituminous tiles, carpet materials with fine-grained protective layers. If the slopes have a slope of up to 15 - 20 °, the yokes are set as the main obstacles. Increasing the slope requires the addition of other snow retention systems.

The elements are fixed at a distance of 0.5 meters along the width of the roof, and a gap of 10-15 cm is left along the length. Snow holders are installed simultaneously with the installation of flexible flooring, since the fastener of the tooth is under the roof structure.

Calculation of the number of rows:

- angle of inclination 30 - 40 ° - 2 rows, 4 pieces are placed per 1 m2;

- tilt 40 -70 ° - 3 tiers, 6 pieces are provided for 1 m2.

If the fasteners of the yokes were not mounted during the installation of the roof, put external brackets and use lattice and tubular snow holders, metal strips.

DIY technology

They make angle-type detainers on their own, thereby saving money. You will need a sheet of stainless steel with or without a polymer protective layer. The pattern of the product is performed on cardboard using a ruler and a marker, then transferred to a sheet and the workpiece is cut out of metal with scissors.

The angle of the bar is made on a bending machine. As a result, a part of 6-10 cm in height with two shelves for fixing is obtained. Holes are made in one half for inserting self-tapping screws using an electric drill. In length, the elements are made equal to the size of the roofing sheet or half of it.