Roll materials are developed on the basis of petroleum products. The oldest roofing carpets are roofing felt, roofing felt and glassine. The materials do not conduct water, due to their flexibility, they fit on domed, arched roofs. Flat roll roofing is used to cover large objects, for example, shops, hangars, workshops, and in residential construction it is used for utility buildings.

- The device and features of the roll roof

- Varieties by method of application

- Soft coverings in the form of rolls

- Self-adhesive materials

- Products fused onto the roof with gas burners

- Varieties by material

- By the type of panel used in the production

- By the type of base used

- By types of external coating

- By the composition of the protective coating

- Advantages and disadvantages of roll roofing

- Preparatory work

- Basics of installing roll roofing

- Popular manufacturers

The device and features of the roll roof

Varieties of roll materials differ somewhat in composition. Traditional roofing felt and roofing felt have a low price, and coatings based on modern technologies are distinguished by high quality and are more expensive.

The multilayer material contains:

- base made of roofing cardboard, fiberglass fabric;

- tar, bitumen or polymer impregnation;

- protective dressing from grains of silicon, quartz, mica in the form of grains of different sizes;

- lower protective layer of dust-like fraction.

The impregnations impart waterproofness, the upper dressing increases the impact resistance, the lower one prevents sticking during storage and transportation.

Varieties by method of application

The fusion method is often used, since work can be carried out at temperatures below + 5 ° C (except for the last layer). The method reduces the installation time of the coating, since there is no need to warm up the resin.

The next is the method of spraying bitumen emulsions onto the base area before installing the rolls. Aggregates are used that spray the substance onto the surface where the material is applied.

Self-adhesive materials are applied by removing the bottom film and pressing against the base. The simplest and fastest method.

Soft coverings in the form of rolls

These types include the common roofing material, rubemast. A soft roof is sold in rolls 1 m wide, the length varies in the range of 15 - 20 m. Requires the application of adhesive mastic on the surface of the base before pressing the strips. They are joined with an overlap of 15-20 cm, the joints are also glued with synthetic means.

Cold polymer-bitumen compositions are used:

- butyl rubber - MBK;

- bitumen-latex - BLK.

More relevant varieties - glass-insulated, glass-mat, euroruberoid - are distinguished by the characteristics of increased flexibility and resistance to temperature changes.

Self-adhesive materials

Roll roofing materials have a bottom layer of modified bitumen, which is glued to the base and does not require heating. The carpet is laid on cleaned and primed metal, concrete, wood. The surface is pre-treated with a primer, and the wood is impregnated with fire retardants and antiseptics.

The film is removed, the carpet is pressed and smoothed with a roller to expel air bubbles. Before installation, the roll is rolled out and left for 10 - 15 hours to remove irregularities. Works are performed in sunny and dry weather.

Products fused onto the roof with gas burners

The carpet is glued to the base using the technology of melting the low-melting bottom layer. Such rolls are placed on a surface made of non-combustible materials so as not to cause a fire. It is important to regulate the pressure of the flame during operation so that the material does not burn, but only the adhesive layer melts.

Number of layers of roll roofing materials:

- at an inclination of more than 15 ° - perform 2 layers;

- 5 - 15 ° - 3 layers;

- less than 5 ° - 4 layers are used.

The concrete surface is leveled with a screed and treated with a primer (primer).

Varieties by material

The material is made on the basis of organic and synthetic components. Bases made of cardboard, fiberglass are impregnated with fusible or astringent impregnations.

The constituent substances are divided by the type of binder:

- bituminous - roofing material, glassine, glass roofing material;

- tar - roofing roofing;

- rubber-bitumen and bituminous polymer.

The last type of base is torn from two sides with a binder layer that includes polymer additives and a fine-grained filler.

By the type of panel used in the production

The design of the canvas is basic and non-basic. Both types are technological and are used for the industrial method of conducting work.

The first variety is produced by processing cardboard, fiberglass fabric, asbestos cloth. They are impregnated with bitumen, resins, tar and other petroleum products.

Baseless species are produced by rolling mixtures of a mineral substance, crushed rubber, which are mixed with an organic binder (bitumen, resin). Plasticizers and antiseptic additives are added to the composition.

By the type of base used

Roofing rolls get their properties depending on the type of base used in the release.

Products are made on various bases:

- cardboard impregnated with petroleum products and covered with a composition of bituminous filler and cardboard chips (parchment, roofing felt);

- roofing board saturated with bitumen and having a lower layer of greater thickness for the possibility of fusion (rubemast);

- fiberglass and synthetic fabrics impregnated and coated with bitumen and composite components;

- rot-resistant bases made of polymer reinforced fabrics, polyester, polyester.

The last two types are becoming popular, since the tensile strength is increased. Before the material gets cracked, it will first stretch to its ultimate level.

By types of external coating

The coating composition, which is supplied to the roll roof covering, differs in the type and combination of components. The topcoat retains water, gases, protects against the action of aggressive acids and alkalis.

They produce material with types of layers:

- polymeric;

- bituminous;

- polymer bitumen;

- isolated;

- brizol.

The binder is applied in one piece or on both sides, depending on the type of roofing carpet. The layers increase the impermeability to steam, moisture, and increase resistance to decay and the action of ultraviolet radiation.

By the composition of the protective coating

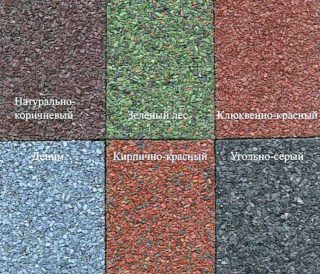

The bedding granules can have different shapes and sizes, consist of organic or synthetic components.

There are types of protection:

- with film and foil;

- sprinkling in the form of grains, scales, dust.

Mineral dressing is used with high hardness, which is inert to chemical reagents. Roofing waterproofing rolls undergo a special treatment for reliable adhesion of particles. Organic dressings are coated to prevent the development of moss and fungus. In areas with hot climates, foil layers have been developed, which are coated with polymer binders.

Advantages and disadvantages of roll roofing

Almost all materials are characterized by low cost and ease of installation.Roll roofing materials are used on large areas where the use of other types becomes economically unprofitable.

The joints of the materials are glued with mastic and form an inseparable connection; welding is also practiced. This method of treatment eliminates the ingress of water into the composition of the roof and maintains its integrity for a long time.

The disadvantage is that the coating is classified as a flammable group and therefore its use is limited. In modern developments, the fire resistance of roll materials has been increased.

Preparatory work

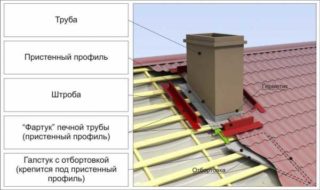

The base is cleaned of dust particles and dried using a burner. The surface is leveled, reinforced in weakened areas of the roof, for example, valleys, gutters, around chimneys, sewer outlets.

If the rolls are rolled out on an old profiled sheet cover, the irregularities are filled with non-combustible material. This is done in the area of the cornice, overhang, along the ridge and abutments to other structures. The filled areas must be at least 25 cm wide.

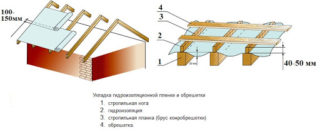

Before laying the rolls, they arrange waterproofing, put insulation. Cement surfaces are primed with cold compounds, and wood is putty with hot mastic.

Basics of installing roll roofing

A team of three is working upwind. The type of mastic depends on the slope of the slopes and the material.

Rolls are placed in one direction, the rule is observed:

- up to 15 °, the strips are rolled parallel to the ridge;

- more than 15 ° - perpendicular to the overhangs and ridge.

Do not cross-glue the rolls. The first layers are made with lining types of material, the outer covering is made with roofing. On modern materials, the overlap of the layers is indicated on the sides. First, mastic is applied to the area, then the stripes are aligned so that all the points coincide. The types to be welded are rolled out simultaneously with the heating of the lower layer and the pressing of the laid area.

Popular manufacturers

Manufacturers have appeared on the construction market using new technologies for the manufacture of roofing carpet. A composite coating is used, consisting of two main layers and a three-layer bitumen. In addition to the usual roofing felt and roofing felt, new types are created that have a high price, but differ in quality characteristics, a quick method of rolling and fastening. Such options serve for more than 30 years without losing the properties declared by the manufacturer.

Company TechnoNIKOL offers varieties of premium, business, standard and economy class.

In each category, there are various modifications and leaders in roofing:

- In the premium group, Technoelast DECOR is used more often. Used as a roof or a kind of design technique. The material is highly resistant to fire.

- Among the roll roofing of TechnoNIKOL business direction, the series Ekoflex, Uniflex are popular, which are installed without problems on any type of base. Such a coating remains elastic at a frost of -5 °.

- The standard group is represented by the Bipol and Linocrom modifications. Rolled carpets are suitable for the installation of a new roof covering, maintenance and overhaul of the old one.

- The economy group is represented by the Bikrost line and is distinguished by high waterproofing qualities. The layers are lightweight. It is enough to put 2 - 3 layers according to the instructions.

TechnoNIKOL materials meet the standards and requirements of moisture resistance, heat resistance strength, they are tested under certain conditions.

Omskkrovlya produces materials using oil products from the West Siberian field: glassine, roofing material and rubemast. The advantages of the products are in high-quality initial raw materials, the use of innovative equipment and technology.

Brand materials Spoli (Slavutsk plant) are represented by polymer-bitumen fused types based on rotting synthetics.There are varieties for top and bottom roof carpets.

Brand Border (Ryazan plant) in production uses polyester fabrics from German and Spanish manufacturers. High-quality roll materials are obtained as a result of selection of raw materials, additions of foreign-made homogenizers.

Membranes of Italian manufacturers Index produced on the basis of polymer modified bitumen with glass fibers and polyester. They differ in durability, increased elasticity, tensile strength.

https: //