After acquiring a land plot, you should start building and basic internal improvement of a temporary change house. Such a building will be needed to store the tool at the initial stage of construction, workers can wait out the bad weather in it, in some cases and spend the night. As a rule, the building shed is erected by the owner of the land plot with his own hand.

Types, purpose and characteristics of change houses for construction

Structurally, the building change house can be:

- panel room:

- frame;

- log or timber;

- brick.

There are two more main types of such structures, differing in layout:

- vest;

- trailer.

The carriage is located on the side, there are no partitions inside. If a change house for inventory is needed on the site, a partition is mounted inside the house at a distance of no more than 2 meters from the entrance. In this case, a small vestibule-changing room and a storage room for tools are formed.

The undershirt is in the middle, the vestibule 1.5-2 m wide is formed inside the room with the help of two transverse partitions. It is used as a dressing room. If you install another partition in the vestibule, it is quite possible to equip a pantry or a bathroom in the resulting room. The other two compartments are used to equip an office, bedroom, kitchen or dining room.

Any change house for builders requires laying at least a light foundation. The only exception is the buildings of the panel assembly.

Shield change houses

Change houses assembled from shields are easy to manufacture. The construction of such structures does not take much time, but they are most often used as temporary storage facilities for storing inventory and building materials.

At the end of the work at the facility, the need for such structures almost immediately disappears, they are disassembled, the component parts are used, for example, for the manufacture of panel formwork.

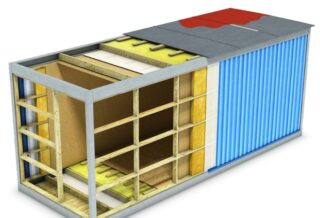

Frame structures

The construction of frame-type cabins is carried out using wooden blocks or metal rails. Such frames are sheathed with any available material: sheet metal, boards, OSB plates, etc. Quite good structures are also obtained if you use sandwich panels. However, trailers assembled on the basis of metal frames have the greatest durability.

Log structures

Log cabins or lumber cabins are the most durable and respectable structures. With high-quality assembly, they look normal on any site (summer cottage, cottage, etc.). Upon completion of construction, log buildings can be used as storage, utility or even living quarters.

Of the shortcomings of log structures, their relatively high cost and the need to lay a strip shallow or columnar foundation are noted.

Construction of a change house with your own hands

Most of the cabins on construction sites are frame structures. It will not be difficult to independently carry out the construction of a temporary trailer, even for a person who does not have much experience in carrying out such work. Little building materials are needed.

All wooden parts of the building shed must be treated with antiseptic and flame retardant materials. This will protect the wood from premature decay and also prevent accidental fire.

Site preparation and foundation laying

Work on the construction of a construction trailer begins with the preparation of the site. The place for it is first cleared, then aligned horizontally and marked along the contours of the future foundation.

On a marked site, a layer of soil is removed to a depth of 10-15 cm. In the resulting small pit, they successively fall asleep and carefully tamp layers of sand and crushed stone. Then a formwork is placed along the perimeter of the site, the height of which depends on the planned location of the change house floor relative to the ground. The entire area intended for pouring with concrete is covered with a reinforcing mesh made of reinforcement, which should be located in the middle of the concrete layer.

The site prepared in this way is poured with concrete in one go. Before the mortar sets, several foundation bolts (anchors) are installed along the contour of the base.

Instead of pouring concrete on the site, you can install foundation blocks and lay on them 2-3 layers of waterproofing, for example, roofing material.

Assembling the frame

After the work on laying the foundation is completed, they begin to assemble the frame. For the base of the latter, a lower strapping is used (4 wooden beams with a section of 100x50 mm), which must be securely fixed. The whole frame will be assembled on them.

Further, in the corners of the foundation, racks are installed, placed strictly vertically - they will then be connected to the upper strapping, which plays an important role in the installation of the roof.

Each post is attached to the base with mounting brackets. In addition, it is recommended to reinforce them with temporary supports.

Roof and floor installation

As a rule, the shed is covered with a gable roof, the installation of which is extremely simple:

- Rafter beacons are mounted on both sides.

- The rafter beacons are interconnected by a transverse beam.

- Rafters are attached to the lighthouses.

You can also equip a pitched roof. To do this, make one wall below the opposite one, then mount a row of rafters and lay roofing sheets on them.

Any material can be used as a roof covering, however, corrugated board or simply sheets of galvanized iron are most often used.

If the cabins are operated during the cold season, the roof must be insulated from the inside. The best material for this is mineral wool.

Having completed the installation of the roof, they proceed to the arrangement of the floor, which, as a rule, is made two-layer (rough and final). With the small size of the change houses, the bars of the lower strapping serve as supports for the subfloor. With a large area of the room, intermediate logs are added. Logs are attached to the rough floor for finishing. The space between the rough and the finish is sewn up with windproof material and filled with insulation. Then a finishing floor is laid, for which OSB sheets or planed boards will fit.

Wall cladding

Experts advise wall cladding with clapboard or OSB-plates. The latter are treated with an antiseptic during the production process and are not at all afraid of moisture. In addition, they are warm enough and, with additional insulation with mineral wool, allow the trailer to be operated both in summer and in winter.

The walls of the frame are sheathed on both sides. Insulation is laid inside. Having completed the processing of one wall, proceed to the next.

Additional expenses

Additional costs that must be taken into account in the construction of cabins-change houses include the independent manufacture or purchase of ready-made doors and windows. The presence of windows, even miniature ones, is mandatory in such rooms. In the most extreme case, they will provide air ventilation.

In the change house, it is desirable to have electrical wiring - several sockets and artificial lighting in such rooms will not interfere.