Often in residential areas outside the city, you can see wooden houses. This material is popular because of its durability and low thermal conductivity. With its help, original projects of structures are created that do not require additional finishing. To build a house from a bar with your own hands, you need to choose the right type of it, make calculations of the required number of elements, and also consider in detail the technology for carrying out the work.

Varieties of timber

The beam is made of wood, cutting off the logs. Its section is rectangular or square. The size ranges from 10 × 10 cm or 40 × 40 cm. The material can be used to build houses on a light foundation. A favorable atmosphere is formed inside such a structure. For construction, profiled, planed or glued material is used.

Planed

Planed timber is the simplest type of building material, for which 4 sides of the edge are cut off from the log. No sophisticated processing equipment is required. Additionally, the surface of the elements is sanded. There is no mechanical damage on the timber, it does not require additional processing.

The driest raw materials are used for production. The specified material has the following qualities:

- availability;

- low price;

- ecological cleanliness.

Such a log house is not easy to lay, since there are no longitudinal profiled grooves. The timber has natural moisture, therefore, after the completion of the construction of the building, it takes time for it to shrink. Over time, cracks may appear in the material as it dries up. Construction is accompanied by additional costs for finishing and thermal insulation of the house. Untreated timber is susceptible to fungal attack.

Profiled

This type of timber is made from a solid log. After additional processing, the product has a complex cross-sectional profile. The surfaces of the elements do not need additional finishing. There are locking joints on the bar, ensuring the most snug fit. The house turns out to be durable and warm.

Profiled timber has the following qualities:

- no need to caulk the walls: jute is placed only in corner and end joints;

- decorativeness;

- reliability of connections;

- high quality workmanship of the material;

- ecological cleanliness.

Profiled timber with natural moisture is subject to shrinkage, during which cracks may appear on it.

Glued and double

Glued laminated timber is considered one of the best materials for building a house. It is a product assembled from individual elements glued together under high pressure. Each of them is laid in the opposite direction of the fibers, so the material is very strong. At the same time, the lamellas are solid or spliced.

Since the percentage of moisture in such a bar is low, it is practically not subject to decay. Complex projects are built from it. In addition, the material is not subject to shrinkage, so further finishing can be done immediately, although it is not often required. Glued laminated timber is expensive.

Double timber - a whole structure made of laminated veneer lumber. The connection of the elements is a sealed lock that is not blown out.There is a heat insulator between the outer and inner elements. The distance between them is 13-15 cm. This design is heat and energy efficient, environmentally friendly. The shrinkage of the house when using a double bar does not exceed 2%.

The advantages of a bar

Before you build a residential building from a bar, you need to consider its merits. They depend on the type of material. An ordinary timber has a low cost, the assembly speed of the structure is high. The profiled material is distinguished by the fact that it does not need to be additionally processed at the assembly site. After installation, there are no gaps between the timber. A completely house from such material can be built in 2 months. This does not require the arrangement of a heavy foundation.

Glued laminated timber has the following advantages:

- high quality raw materials;

- no shrinkage, as well as complete preservation of the geometry of the elements under the influence of moisture or other external factors;

- high strength;

- no need for finishing;

- quick installation; the ability to lay the material yourself.

Insulated structures are very strong, durable and provide maximum thermal and acoustic insulation. It takes less money to heat the house. In addition, the structure is lightweight, so no foundation reinforcement is required.

Selection of timber sizes and calculations

You need to build a house after the required amount of material has been determined. Initially, you need to make a drawing of the future structure. For this, terrain measurements are made. If a house diagram has already been drawn up, the following data are required for the calculation:

- the total area of the walls (door and window openings are not deducted, since they are cut out after the structure has shrunk);

- length and cross-section of the material;

- quality and type of timber.

For a small residential building, elements with a cross section of 15 * 15 cm are used.If it is planned to build a cottage or a large structure, a material of 20 * 20 cm is suitable. The length of the element is 3 m or 6 m. If you plan to build a house 10 * 15 with a room height of 3 m, the calculation carried out like this:

- (10 + 15) * 2 + 6 = 56 m (building perimeter);

- 56 * 3 = 168 m² (total area);

- required volume of timber: 168 * 0.15 (section in m) = 25.2 m³.

It is also necessary to take into account the presence of partitions between rooms. To the total volume, you need to add another 10% of the material.

Required tools and materials

For the construction of a log house from ordinary material, additional consumables are required:

- wooden boards for creating a roof lathing, making dowels, laying a rough floor covering;

- waterproofing (in this case, roofing material is used to protect the foundation and roof);

- pins: they are facets or a cylindrical nail for fastening the rows together (they are made using a band saw or miter saw);

- heat insulator (synthetic materials for wood will not work, you will need flax, tow or felt);

- fasteners: staples, nails, screws or pins;

- antiseptics and fire retardants (use film products or impregnations).

In addition to additional materials, you need to select the necessary tools:

- building level, plumb line, tape measure, square;

- chisel, plane;

- hammer, sledgehammer and mallet;

- hacksaw or jigsaw;

- drill for making holes and grooves;

- circular and miter saw.

The drill requires special wood drills, the thickness of which is 2.5 cm.

Do-it-yourself construction of a house from a bar

To build a house from a bar correctly, you need to follow the step-by-step instructions. First of all, you need to prepare for work. They choose a suitable place on the site, calculate the amount of material and the operational mass of the structure, determine the bearing capacity of the foundation. Now you can make a drawing of the house with the exact indication of all dimensions.

Next, follow the instructions:

- Erection of the foundation.Since a house made of timber is not the heaviest, a tape type of base with reinforcement is suitable. It is necessary to take into account the thickness of the walls with an addition of 5-7 cm in both directions. The depth of the foundation is 10-15 cm below the level of soil freezing. First, the fertile soil layer is removed, the structure is marked out depending on the requirements of the project, and trenches are dug. The width of the pit should be such that the base can be easily waterproofed. A cushion of sand and crushed stone is placed on the bottom, which is compacted. Now you can install the reinforcement and pour the concrete. As soon as it matures, it is covered with roofing material.

- Walling. First, all wooden elements are treated with an antiseptic. After that, the wedding board is mounted along the perimeter of the base. The section of the first crown is 20 * 15 cm. Jute or tow is placed between it and the subsequent parts of the structure. To connect the crowns, pins are required, which are located at a distance of 1-1.5 m from each other in a checkerboard pattern. 2.5-3 m recede from the edges of the fixing bowls of the timber. At the same stage, the joists of the floor and ceiling ceilings supporting the internal walls are installed.

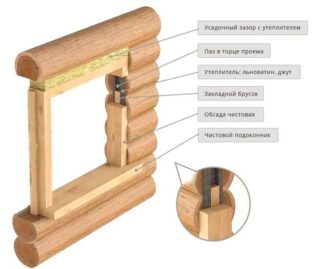

- Manufacturing of window and door openings. When assembling the windows, the sidewalls are first mounted, then a threshold (window sill) is placed, and last of all, the upper element. All fresh sections are treated with an antiseptic.

Further construction work is carried out after the house has shrunk. This takes from 3 months to 3 years. Moreover, not all crowns and bars can settle evenly. The gaps that appear must be caulked from the inside and outside of the structure. Now you can erect a rafter system and build a roof.

In the last turn, the installation of finished window and door blocks is carried out. The openings require insulation. Platbands are installed on the slopes. If you want to emphasize the natural beauty of the house, the surface of the wood is sanded and varnished.

If the winters are cold, external wall insulation is carried out, followed by finishing with clapboard, vulture panels.