An excellent material for building a summer cottage is a foam block. Buildings of this type have absorbed the positive properties of wood and brick. The correct approach to business will allow you to fully take advantage of the technology and minimize its disadvantages. First you need to familiarize yourself with the features of foam concrete and the building codes applicable to it.

The composition and advantages of foam blocks

When deciding to build a country house from foam blocks, you should familiarize yourself with the range of products on the market. It varies in composition, shape, size and performance.

Blocks are made from the following substances:

- cement;

- sand;

- lime;

- plasticizers;

- pigments;

- special foaming agent.

The stones have an open-type porous structure, which ensures their light weight and low thermal conductivity.

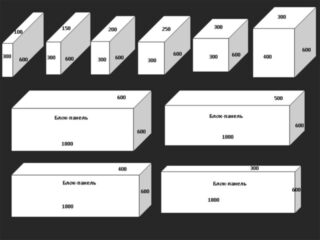

The material can have the following dimensions:

- length - 40-80 cm;

- thickness - 10-40 cm;

- height - 20-40 cm.

Also in construction there is a classification in relation to the density of foam blocks and the corresponding thermal conductivity coefficient:

- D400 - 0.88 W / (m • K);

- D500 - 0.12 W / (m • K);

- D600 - 0.22 W / (m • K).

Grades D100-300 are used as insulation, and D700-1200 for the construction of heavily loaded walls in multi-storey buildings with reinforced concrete floors.

According to the manufacturing method, the following types of material are distinguished:

- non-autoclave - cooling and crystallization occurs in natural conditions;

- autoclave - forms with a solution are fed into the furnace, where they are exposed to high temperature and superheated steam.

Developers believe that the main advantage of a country house made of blocks is the combination of large size and low weight of blocks, which ensures convenience, accuracy and high speed of their construction.

In addition, the following advantages are noted:

- the accuracy of the geometry of the faces;

- low thermal conductivity;

- ease of processing.

The disadvantages include fragility and hygroscopicity.

Drawing up a project of a country house from foam blocks

The basis for the success of the construction of a cottage from foam blocks is a competently conducted planning of the upcoming work.

The project should take into account the following nuances:

- Lightweight but solid foundation. The best option is a shallow tape, submerged at least 60 cm with a basement height of more than 40 cm.

- Maximum wall height. For D500-600 brands it is 300 cm. D800-1200 - 600 cm, D300-400 goes to internal partitions.

- Every 2 rows, reinforcement with at least two steel rods with a diameter of 6-8 mm should be carried out.

- Each level should be reinforced with an armored belt 20-40 cm high.At the same time, the penetration of the pins into the walls should not be less than 40 cm.

- Gas blocks absorb moisture well. It is necessary to use effective impregnations, plasters or vapor barriers.

- The structure of foam concrete does not differ in strength and density. You should choose through or deep methods of attaching various external structures to it.

Build a country house from foam blocks should be in dry and warm weather. In the cold, the adhesive solution will freeze, and precipitation will spoil the material.

Required tools and materials

A block cottage is not only load-bearing walls and partitions between them. The construction of the building starts from the zero level and ends with the installation of the roof covering.Based on this, a fairly extensive set of tools and materials will be required.

For strip foundations:

- shovel;

- concrete mixer;

- level;

- roulette;

- Bulgarian;

- cement, sand, crushed stone;

- fittings;

- formwork;

- putty knife.

For walls:

- waterproofing;

- blocks;

- fittings;

- wall chaser;

- notched trowel;

- mallet;

- level;

- adhesive composition;

- everything for the armopoyas - reinforcement, formwork, concrete, studs.

For the roof:

- hacksaw;

- a hammer;

- nails;

- beams and floor boards;

- timber for the truss system;

- slats for lathing;

- wind protection and vapor barrier;

- insulation;

- roof covering;

- additional elements.

You should remember about safety precautions. The construction site must be fenced. Goats are required, as well as insurance, a safety helmet, goggles and gloves.

DIY construction

You can start construction with a long-term forecast of good weather. Just in case, you should stock up on dense cellophane from the calculation of covering the new building at any stage of its construction.

A country house made of foam blocks with your own hands is made in a certain sequence.

First, the markup is carried out. The exact location and topographic orientation of the building is determined. Trace in progress. The site is cleared of debris and household items.

Then the foundation is built:

- Digging a pit, leveling and compaction of the bottom.

- Laying geotextile fabric. It prevents the germination of grass and bushes, erosion of the soil under the contour.

- Backfilling of sand and gravel cushion.

- Laying waterproofing. Cellophane or roofing material is used.

- Formwork installations.

- Installation and fixing of the reinforcement cage. Better to knit it with wire.

- Preparation and pouring of concrete. Leveling the surface of the mortar.

The foundation should gain strength for 21-28 days with daily watering and shelter from the sun.

The next step is to remove the walls:

- Leveling the base with cement mortar, if the height difference is more than 1.5 cm. It is economically unprofitable to do this with an expensive adhesive.

- Laying waterproofing. It is better to use roofing material glued to the melted bitumen.

- Setting the level. For this, steel pins driven into the corners are used, between which the cord is pulled tightly. The height is taken over a brick installed at the highest point of the foundation.

- Laying out the corners. Two stones are used on each side. Then the exact setting of the height along the stretched line is carried out. Differences are leveled with glue.

- The first two rows are made. The excess at the joints is carefully trimmed with a grinder or a hacksaw with fine teeth.

- Reinforcement is made after each pair of levels. Parallel grooves are made on the surface, rods are laid in them to form a closed contour. Then the grooves are filled with mortar, the edges are leveled.

- Bridges are placed in the places of windows and doors. Reinforced concrete posts or hollow profiles are used. The recesses are reinforced and filled with concrete.

In all cases, an armo-belt is installed over the aerated concrete walls. It is done like this:

- Preparation of fasteners. Through holes are drilled along the top of the walls, pins are inserted into them. Another option is to drive in the steel pins at an upward angle.

- Installation of formwork panels. Used boards, plywood, other sheet materials.

- Knitting of the reinforcing cage. It is advisable to use a wire and a hook.

- Preparation and pouring of concrete. This is done from the corners to the center, the solution is compacted, the surface is leveled.

Roof arrangement:

- Overlap manufacturing. It is made from timber and boards or solid or several hollow reinforced concrete slabs.

- Installing the Mauerlat. This design accepts and evenly distributes the load along the armored belt.It is advisable to use wood that is impervious to dampness and insects.

- Manufacturing of the rafter system. It is carried out in accordance with the selected type of roof.

- Creation of a roofing "pie". The lathing, vapor barrier, counter-lathing, outer covering and additional parts are fastened in stages. Then, from the inside, between the rafters, insulation and interior decoration are inserted.

After the construction of the main structures, windows and doors are installed, communications are laid.

Exterior decoration of the house

The appearance of the walls is not presentable, plus they absorb moisture well. Therefore, the exterior finish has a protective and aesthetic function. When choosing the material and style of cladding, you need to focus on factors such as the design of nearby buildings, site design and climate features. Consideration should also be given to the likelihood of exposure to vandals.

The options are:

- siding;

- sandwich panels;

- decorative plaster;

- composite boards;

- a natural stone;

- ceramic tile;

- plastic panels;

- silicone paint;

- imitation of a bar.

Any decision will be correct if it is technologically justified, and its appearance evokes positive emotions in others.

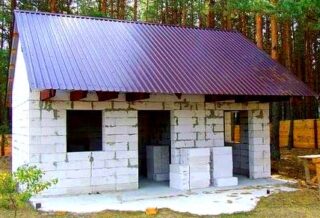

I myself built such a winter road on enthusiasm. I did everything as it is pictured here. did not stop did not collapse I live there for 10 years