Modern technologies allow the construction of residential buildings at any time of the year and in a short time. At the same time, the quality of the final result is no worse, and in many respects even better than that of buildings made of time-tested bricks and solid wood. A house from OSB panels can be removed within two to three weeks with a limited budget and without the involvement of specialists. Only frame structures can be made cheaper and faster, but their operational characteristics are somewhat lower.

Description of OSB panels

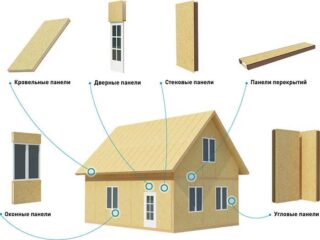

OSB panels are structured slabs, which are at the same time an element of masonry, thermal insulation, interior and exterior decoration.

Product device:

- Bearing elements. They are made of oriented strand board up to 16 mm thick.

- Insulation. The most commonly used extruded polystyrene foam treated with fire-fighting agents. Basalt wool is used less often.

- Binding element. The connection is made using high-strength and waterproof polymer glue.

When building a house from OSB panels, parts with a height of 250-280 cm, a width of 65-125 cm and a thickness of 150-220 mm are used. Also, manufacturers produce special roofing boards with special locks that ensure tight joints at certain angles.

Advantages and disadvantages of the material

The material has a long history of use in private construction, has proven itself well in the most difficult climatic conditions.

The main advantages of OSB panels:

- Low weight with large area and volume. There is no need to build a powerful and expensive foundation. Pile and columnar foundations are quite enough.

- Excellent insulating properties. Plates block heat and frost outside, dampen almost all internal and external noises. A significant reduction in heating and air conditioning costs is achieved.

- Low cost per square meter of the building. The opportunity to save money.

- Short construction time. Raising a house resembles manipulating a children's designer. In most cases, the assembly does not take more than a month.

- No shrinkage. The slabs retain their shape even under load. Finishing can be started immediately after fixing them.

- Versatility. A house made of OSB panels is suitable for temporary and permanent residence, including during the cold season.

Cons of material:

- Use in the manufacture of synthetic materials. When polystyrene burns, it emits toxic fumes. The bonding agent in the boards are resins containing formaldehydes, which are extremely hazardous to health.

- Lack of ventilation qualities. Inside the house there is a thermos effect. Organization of effective forced ventilation is required.

- Limited strength. With all its advantages, OSB is inferior in this respect to brick, timber and even foam concrete.

The existing shortcomings are not so critical that they cannot be eliminated or the impact is minimized.

Varieties of OSB panels

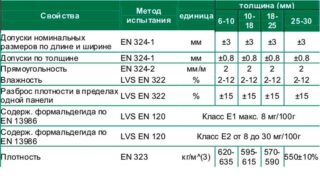

OSB production is regulated by European and Russian standards. In the Russian Federation, GOST R 56309-2014 has been developed, the provisions of which comply with the norms set forth in the EU standard EN 300: 2006.

In accordance with these documents, the range of plates is divided into the following brands:

- OSB-1. Have a small thickness and strength, the minimum percentage of formaldehyde resin. It is used for arranging partitions in residential buildings and light street buildings.

- OSB-2. Average load level. They are used for the construction of houses, summer cottages and garages in dry climates.

- OSB-3. Versatile structures with increased load-bearing capacity. Designed for use in humid environments.

- OSB-4. High strength products for highly loaded structures. No restrictions on installation conditions.

There is also a classification of boards regarding the level of formaldehyde content. Products of classes E0.5 and E1 can be used in residential buildings and public premises. E2 class of emission indicates that such material can be used for the construction of production and utility rooms that are not associated with the storage of products, long-term stay of people and animals.

Features of house installation

A feature of construction from OSB panels is that they themselves have a high bearing capacity.

House build options:

- Wireframe method. In this case, a frame is constructed from a bar (preferably glued). Then slabs are inserted into the cells. In a damp climate, an expansion gap of up to 3 mm is made based on the swelling of wood with moisture.

- Frameless way. Here the panels are fastened to each other using strips-inserts. The technology is faster and cheaper, but it is associated with the impossibility of replacing the damaged fragment.

- Assembling from a ready-made house kit. This is a set of cut to size and marked parts. It includes timber, plates, fasteners, and, if necessary, insulation materials. All you need to do is follow the attached instructions.

- Self-planning. The developer himself makes the project, purchases everything necessary according to the calculations and erects the building. The foundation issue is decided individually.

The choice of approach to construction is made based on their own financial capabilities and artisan skills.

DIY construction technology

The step-by-step process for completing this activity is as follows:

- Marking on the ground, tracing, clearing the site from debris and vegetation.

- Foundation making. A pile-grillage or light insulated slab base is made.

- Securing the bottom harness. It is advisable to use larch or cedar timber 200x200 mm.

- Installation of vertical racks. The spacing and height between them is taken in accordance with the width and length of the panels. After alignment, the supports are fixed with boards and bars.

- Installation of vertical strapping. Fastening to the racks is carried out on nails, corners or screws. Then the props are removed.

- Fastening of transverse partitions in places where windows and doors will be located.

- Treatment of a wooden frame with an antiseptic and hydrophobic impregnation.

- Installation of slabs into openings. They are pre-filled with polyurethane foam, the bottom supports are laid. After placing the panel in the frame, it is aligned with side inserts.

- Overlap arrangement. If OSB-4 class products are available, you can use them without laying the logs. It is necessary to seal the joints and nail the plates to the strapping.

- Installation of Mauerlat and ridge bar. After that, panels are laid on them, rafters are optional.

In conclusion, additional parts are installed.

At the initial stage of the construction of the building, the site should be enclosed with a fence in order to prevent children from entering the object of increased danger. Construction must be carried out in goggles, gloves and a mounting helmet. When climbing to a height, use stable scaffolding and fall arrest devices. Particular care should be taken with regard to fire prevention. It is forbidden to smoke and use open fires near the house.