The building material is an artificial stone of a porous-cellular structure. Elements are produced in a certain size for the construction of light and warm buildings. A house made of foam blocks will retain heat 2-3 times more efficiently than a brick building. Modern material is produced using improved technologies, so the foam block is gaining more and more popularity.

- What is a foam block

- The difference between a foam block and aerated concrete

- Choosing a foam block for building a house

- Advantages and disadvantages of the material

- Design and calculations of foam blocks for home

- DIY house building instructions

- Walling

- Overlapping device

- Roof installation

- House insulation from foam blocks

- Exterior wall decoration of the house

What is a foam block

The wall structural material contains a cement-sand mortar, to which an organic (protein) or artificial foaming agent is added. Allow the introduction of fiber fibers, ash, clay and other fillers.

The solution is mixed with the supply of foam, as a result, the mass increases in volume and solidifies with the formation of many cells isolated from each other inside. The blocks are dried and kept in molds for 28 days, during which time the stones receive 100% strength, and they can be used for construction.

Synthetic foam makers reduce the cost of production, but the output is products of low quality and strength. Protein foaming agents are reliable, have better adhesion to the solution, and have more powerful partitions between the cells. The density of the material is controlled by the dosage of the foam former.

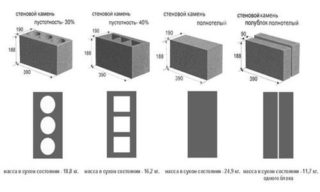

Grades are distinguished by density:

- heat-insulating varieties - from D300 to D500, low strength and thermal conductivity, set as an insulation layer;

- structural and thermal insulation - from D500 to D900, used as a building material with simultaneous protection from the cold;

- structural foam block - from D1000 to D1200, are distinguished by increased strength, but thermal insulation properties suffer, they are used for walls and partitions.

Elements are designated by letters and numbers. Strength is indicated by the letter B and a number from 0.5 to 60, which indicates the load that the stone can withstand. Frost resistance is indicated by the letter F, a number from 15 to 75 indicates the area of application. Numbers up to 25 are recommended only for installations in heated rooms.

The difference between a foam block and aerated concrete

Chemical converters are not used for the production of foam concrete, only foam. It is poured into molds for drying or blocks are cut on machines.

Aerated concrete contains Portland cement, fiberglass, water and sand, and the pores are obtained by adding a gas-forming component. Most often, an aluminum mixture is used, which enters into a chemical reaction and releases gas. The mold is not completely filled so that there is volume to increase the mixture. The result is a mass with open and interconnected cells.

The difference in the properties of the foam block and aerated concrete:

- Geometry of stones. The difference in technology leads to the fact that the dimensional accuracy of a foam concrete block can vary by 3 mm, while for aerated concrete an error of only 1 mm is allowed.

- Thermal insulation qualities. Aerated concrete has a low density, so it conducts less heat. But the difference is insignificant, since both materials produce structural and insulating grades.

- Moisture absorption.The foam block is non-hygroscopic; houses from foam concrete can be erected without waterproofing. Open cell aerated concrete is vulnerable to water and requires protection.

- Strength. The indicator depends on the density. For aerated concrete, which is released under pressure, the strength is higher, the material is allowed to be installed without reinforcement. Foam concrete requires a metal frame.

The weight of the materials is approximately the same, but the foam concrete is slightly heavier.

The durability of foam concrete and aerated concrete ranges from 100 years, subject to the technology.

A more correct geometry of aerated concrete allows you to reduce the consumption of glue or mortar. The surface of the wall made of foam blocks requires careful leveling.

Choosing a foam block for building a house

For private construction (load-bearing walls), blocks with a density of 1 - 1.2 t / m3 (D1000 - D1200) are chosen.

Structural types are distinguished by the method of laying, there are varieties on the market:

- monoblock of classic shape;

- hollow stones;

- Lego foam block for simplified installation in vertically placed fittings.

Grade is important if a foam concrete house will not be finished from the outside; in other options, the second grade can be used. Products of lower quality allow chips and small dimensional defects on the surface. Installation from second-rate blocks will increase the consumption of mortar and the time for choosing the position of the stone during laying.

The material of the third grade is distinguished by large violations of dimensions, shape, its structure uniformity is partially changed. For a private house, it is better not to take such blocks. When buying, you need to require a certificate of quality, since a lot of material is produced by handicraftsmen on imperfect equipment.

Other selection criteria:

- The size of the cells (air cavities). For insulation, large-porous specimens are needed, and the construction of vertical fences is carried out with fine-mesh stones.

- Storage conditions. Do not install packs in several rows, as strength will suffer. This is especially important for a freshly prepared foam block.

- Item color. The lighter the stone, the less binder (cement) it contains.

The determining final factor is the price of a certain brand of foam block. Depending on the region, the cost can be from 2300 to 2900 rubles per 1 m³. Price includes purchase and delivery costs. If the indicator is underestimated, you need to find out the reason.

Advantages and disadvantages of the material

The positive qualities include good protection from the cold. A wall made of foam concrete stones is 2 - 2.5 times thinner than a brick fence. The porous structure provides reliable sound insulation.

Other benefits:

- Inertness to moisture ensures the frost resistance of the walls. The constructions can withstand multi-stage freezing and thawing without changing the original properties. Moisture can be absorbed only by the outer cells, which, due to the cut, turned out to be open, but such a layer dries out quickly.

- Resistant to fire. Foam concrete stones do not burn, do not smolder, do not emit harmful components when heated.

- Convenience of processing. Elements are easy to saw, mill and drill. They can be used for sewerage, water supply.

- Fast laying. Due to the large size and lightness, the elements are installed faster than small-sized bricks. The consumption of the solution decreases per square of masonry.

- Saving on the foundation. Due to the light weight of the buildings, they do not require a massive base, so less materials are used for installation.

- Low cost, taking into account that the insulation layer will decrease, waterproofing will be canceled.

The safety of foam concrete depends on the manufacturer. If the composition contains waste from metallurgy or the production of building materials, environmental friendliness need not be mentioned.

Fragility and unassuming appearance are considered disadvantages.The first disadvantage manifests itself if a low quality of blocks is selected or the strength calculation is performed incorrectly. The gray color of the stones looks ugly, you need a decorative finish on the outside.

Design and calculations of foam blocks for home

Projects of houses from foam blocks are made to select an economical option for the construction of housing and the correct calculation of the volume of materials. The estimate includes the cost of structures, materials, wages of workers. It is necessary to calculate the consumption of electricity, the cost of machines, mechanisms, as well as the delivery of materials and overhead costs.

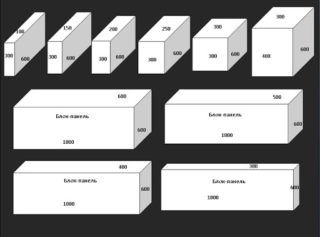

To determine the consumption of the foam block, you need to calculate separately the volume of the outer walls and inner partitions minus the openings of windows and doors. When calculating, the thickness of the wall is taken into account, since the stone can be placed in length or width and get a wall of 30 or 20 cm.External and internal walls are laid from stones 60x30x20 cm in size, and elements of 60x30x10 cm are placed on the partitions.

Calculate the volume of one foam block. The block for the outer and inner walls has a cubic capacity of 0.036 m³, and the partition element - 0.018 m³. The volume of the outer part is divided by this value; separately, the volume of the partitions is also divided by the corresponding indicator. Get the number of foam blocks in pieces.

DIY house building instructions

There is a controversial statement that a foam concrete house does not require a foundation. This situation is possible for a temporary structure, such as a barn or greenhouse. A residential capital building will stand for a long time if a solid foundation is laid under it in accordance with the load from the building.

Used for home:

- monolithic concrete tape;

- pillars with girder grillage;

- driven or screwed piles.

The choice of a base for building a house depends on its size and layout, the type of roof overlap. The depth of the foundation and the width of the foundation are influenced by the type of soil and its bearing characteristics. Determine the level of soil water, the thickness of the bedding.

Walling

Foam concrete is not a capricious material, it is placed both on a mortar of cement and sand, and on glue. The choice depends on the correct size and number of chips. The mixture is applied with a notched trowel, the excess solution displaced from the seam is immediately removed. Work is carried out at a temperature not lower than + 5 ° C, and with antifreeze additives in the solution, a foam block is placed up to -15 ° C.

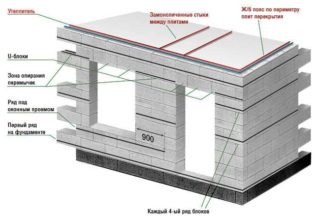

In the process of erecting walls, they are reinforced:

- bottom row;

- subsequent tiers in 4 rows;

- area of openings of windows and doors, arches;

- areas for the installation of floor beams and rafter systems;

- especially loaded places.

Plastic mesh is used when laying on glue when a thin seam is obtained. It differs from the steel gasket in its resistance to corrosion. A metal mesh is used when installing blocks on a solution of cement and sand, it is placed on the wall and immersed in the mixture. For reinforcement, reinforcement with a diameter of 6 - 8 mm is used; for this, a longitudinal recess is made in the block with a grinder.

After laying the first row, the cord is pulled to orient the subsequent tiers. The installation of cameos is carried out with bandaging the seams, the rope is lifted at the end of the next line.

Overlapping device

Due to the increased fragility, a reinforced concrete belt is made before installing the beams around the perimeter of the walls. The width of the structure is equal to the width of the wall, the height of the belt is made 10 - 20 cm. The number of reinforcing inserts and the diameter of the rods depends on the span between the load-bearing walls and is taken by calculation.

A formwork is made around the perimeter, a metal frame is mounted into it, then a concrete mixture is poured. The overlap of beams or reinforced concrete slabs is installed no earlier than after 28 days. Additional cold bridges appear in the places where the fittings are installed, therefore, heat-insulating materials are used to eliminate them.

Roof installation

Mauerlat is laid along the load-bearing walls where the rafter legs will rest.The tree at the junction is waterproofed with roofing material. The slope of the roof is provided from 20 ° so that a mass of snow does not accumulate on the slopes and does not create an additional load on the walls.

Light materials are used for the top coat:

- metal roofing, corrugated board;

- Cink Steel;

- copper sheets.

Rafters are made of beams 10x10, 20x20 or 15x15 cm, they are fastened with metal brackets. Before installation, wood is treated with fire retardants, antiseptics, preference is given to pine, spruce, fir.

House insulation from foam blocks

Buildings made of warm material almost never require insulation from the cold. The need for protection arises when construction is carried out from dense blocks that have an increased heat conductivity. The insulator is installed outside the house, soft insulation is used. The choice depends on the density of the foam block and the vapor permeability of the material, the latter should be greater than or equal to the wall index.

It is required to create a frame in order to mount a waterproofing film against wetting mineral wool, since the insulation loses its properties from moisture. Condensation appears between the layers, so a ventilation gap is needed to bring the building to an energy-passive state.

Exterior wall decoration of the house

Technologically, buildings made of foam concrete do not require external finishing, since the material is in excellent contact with the atmosphere and serves without changing quality for many years. The owners do not always like the unattractive color of the walls; the outer finishing layer is placed for the purpose of decoration.

Cladding is applied:

- front brick;

- vinyl or steel siding;

- clapboard MDF or PVC;

- smooth or decorative plaster with painting.

A combined finish is used, for example, the basement is revetted with ceramics, and the walls are continued in height with clapboard.