The construction of a lean-to canopy is an easy task to implement, but it requires a well-thought-out drawing and structure. Carelessness can lead to the destruction of the building under the influence of various loads. Getting started, you need to choose the design and materials that are suitable for a specific task.

Varieties of a lean-to canopy

The hinged canopy can be adjacent to the building or be an independent shelter on a prefabricated frame. The latter, like the surface of the slope, can be made of different materials.

Manufacturing material

The most reliable and durable of the popular materials for building a canopy is metal. The frame assembled from pipes can have a simple shape or include additional technological or decorative solutions. The structure lasts a long time and does not deteriorate under the influence of precipitation.

The frame can also be made of logs or wooden beams. In this case, the strapping is made of boards or slats. All building materials must be treated with compounds that prevent damage to wood by moisture and fungus.

There are two-piece awnings, the frame of which is made of metal, and the crate is made of wood. The most durable option is stone construction, but it takes a long time to implement.

Functional purpose

The hinged structure protects objects or walls of the house from destructive processes caused by moisture and ultraviolet rays. The use of such a protective device extends the life of the building or vehicle. A similar structure can be used as a decorative element included in the site ensemble. For this purpose, wooden structures are usually installed.

A lean-to resting shed should protect people under shelter from the scorching sun and precipitation. It can be attached to the load-bearing wall of a building or it can be freestanding. If the purpose of building a shed is to protect the car, it is better to carry it out as a separate metal structure.

Features of materials for construction

The covering that protects the structure can be made of different materials. They vary in price and performance.

Polycarbonate

The polymer material has an external resemblance to sheet glass, but is devoid of its main disadvantages - fragility and injury hazard. All this, combined with lightness, makes it attractive for installation work. There are cellular varieties of polycarbonate that have cells. The advantages of the material, in addition to the mentioned characteristics, include:

- minimizing the load on the walls;

- resistance to environmental factors, temperature extremes, most chemical influences;

- good ability to transmit light;

- fire resistance;

- ease of installation;

- long service life without loss of useful properties.

Among the shortcomings, it should be noted the vulnerability of the material to alkaline substances, as well as poor tolerance to abrasive influences. In addition, it tends to expand at high temperatures.

Decking and metal tiles

For the base of such a coating, thin (up to 1.2 mm) galvanized steel sheets are used.The material is highly resistant to moisture, ultraviolet rays, mechanical stress. Due to its thinness, the mass of the material is small, so there is no need to spend money on a hardy crate. The material itself also has a low price. The minus of the corrugated board is the insufficient ability to sound and heat insulation. You need to cut the flooring with a hand hacksaw. The grinder is not suitable for this - when using it, sparks arise that can disrupt the integrity of the sheet coating.

The metal tile is also based on steel, but the material itself is more durable, heavy and reliable. In general, it has the same set of characteristics as corrugated board, but it has the best heat and sound insulation qualities. They are mounted on a roof with a pronounced slope (more than 12 degrees), while corrugated board is also used for shallower structures.

Preparatory work

Before starting the installation work, you need to prepare a drawing and mark the dimensions of the future structure on it. Errors in design can lead to the destruction of the structure or damage to the load-bearing wall.

If the canopy has significant dimensions (width from 5 meters, length from 10), it is worth using the services of specialists to carry out calculations. In such cases, complex calculation algorithms are used, taking into account the characteristics of the soil, as well as the amount of snow and rain that falls in the area at different times of the year.

There are also certain rules for a small canopy. To build a metal structure 6 meters long, you need 4 pairs of supports. The minimum permissible cross-section of the tubes used is 8 cm, and the thickness of their walls is 3 mm. Each of the pairs is supplied with reinforcing trusses made from a 6 cm cross-section. One of the sides is located higher than the other in accordance with the slope angle and the roofing. If polycarbonate is used, 20-25 degrees is optimal. The crate can be made from tubes with a cross section of 4 cm, and the distance between adjacent elements will be 1 m. In winter, such a canopy can withstand up to 4 tons of wet snow.

Before starting the installation and assembly of the structure, you need to buy a sufficient number of profile pipes of the required dimensions. To arrange the recesses where the supports will be installed, it is advisable to find a garden drill. It is necessary to dig holes in advance to prevent the structure from sinking. For a rafter unit, it is better to take rectangular tubes - they are connected easier than round ones.

In general, the installation of a canopy does not require complex preparation: you just need to create a flat area by removing the upper sod layer and tamping the soil. When the structure is ready, you can equip a lawn or lay tiles under it.

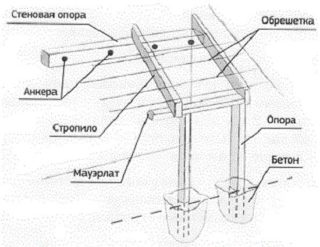

DIY shed construction

When the pits are ready, a drainage sand-crushed layer of 0.1-0.15 m is laid in them. Having rammed it, they mount plastic tubes of suitable diameter and mount the racks strictly vertically. The latter on one side should be located higher in order to create a slope for the outflow of liquid. Supports are used to strengthen the rack elements. A concrete mixture is poured into the recesses (with the plastic pipes performing the formwork function). The supporting elements are united by the upper strapping. In the manufacture of a metal frame, the elements are connected to each other by a welding machine. The lathing can be made from a profile.

Then the roof is installed. Polycarbonate sheets are installed without overlap, connecting them with fasteners. One part of such an element is screwed to the rafter, the second presses the sheets to be joined. Other roofing materials are overlapped. Self-tapping screws equipped with gaskets are used for fastening steel coatings to the crate.