The popularity of frame construction is justified by the speed of construction and lightness of structures, practicality and quite decent strength. The comfort of living is influenced by a competent and thoughtful cake of the wall of a frame house. A well-thought-out multi-layer construction protects the premises from wind and dampness, heat and cold, and the inevitable noise behind the walls. The combination of several materials prevents condensation, mold and mildew growth. Success is determined by the correct choice and application of the material.

Features and device of the cake wall of a frame house

The cake of a frame house is an important component of its design, which is responsible for performing functions such as insulation, vapor barrier, energy conservation. It consists of several elements that complement and duplicate each other. In this case, not only the completeness of the filling of the frame, but also the sequence of the location of each element is of fundamental importance.

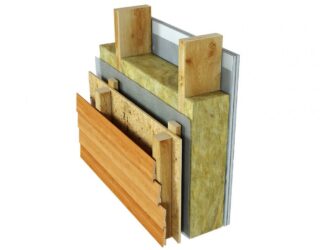

The wall pie schematic contains the following layers:

- The foundation. As a rule, it is a wooden frame assembled from a bar of 150-200x50 mm. Products of massive or glued type are used, mainly from coniferous wood species.

- Insulation. The options can be different - mineral wool, foam, fluffed cellulose, polyurethane foam, expanded clay. Experts consider basalt wool to be the best option.

- Vapor barrier. Located on both sides of the insulation. Provides moisture removal from the inside of the building and prevents its penetration from the outside.

- Lathing. Consists of wooden slats or iron profiles. Presses the membrane to the frame, serves as the basis for interior and exterior decoration.

- Wood board. Protects soft filling fragments from mechanical damage. Provides additional strength to the cellular structure of the building.

- Decorative cladding. Materials with ventilation characteristics are used. Inside, plywood, lining, drywall, imitation of timber are installed, plaster is applied. Outside, a ventilated facade with tiles is made, siding, plastic or sandwich panels are hung.

In most cases, the structure is made in a collapsible version. In order not to do unnecessary work once again, it is better to immediately install high-quality and durable materials.

Factors affecting the parameters of the cake

If the content of the cake is a constant indicator, then the properties of the individual elements can vary significantly.

The selection of materials is based on the following factors:

- Insulation type. For hygroscopic fillers (mineral wool, expanded clay, cellulose), a membrane is required. For foam and polyurethane foam, inexpensive cellophane is sufficient.

- Periodicity of residence. For a summer cottage, a small layer is made. If people live in the house permanently, effective insulation is established.

- Climate. The higher the temperature peaks, the higher the cake performance requirements.

- Finish type. The better its thermal insulation performance, the thinner the filling of the wall becomes.

- Environmental Safety. Almost all materials emit substances harmful to health.To neutralize this phenomenon, appropriate coatings are selected.

There is no excessive insulation. Extremely hot summers or cold winters are bound to happen every few years.

Installation of partitions inside the house

The walls, if they do not fulfill the load-bearing function, are made thinner, but also with the obligatory filling of the internal space.

This is necessary to achieve the following goals:

- Soundproofing. Silence is needed for bedrooms and children's rooms. It will not be superfluous to reduce the volume of noise or completely eliminate them in the kitchen or technical room. A reinforced partition is needed for the corridor and veranda.

- Creation of a comfortable microclimate for a separate enclosed area. This is done when there is no heating system in the house, and property owners use mobile or stationary heaters.

The thickness of the dividing walls can be 10 cm; for functional structures, 15-20 cm are needed.

Features of steam and waterproofing

The main enemy of almost all building materials and comfort inside the building is dampness. Moisture is present in the environment and arises from the process of life inside the building. The task of a vapor barrier is to block water from the outside and effectively drain it from the premises.

To perform these functions, you can use glassine of the simplest composition, more complex polypropylene fabrics or ultra-modern and most effective diffuse membranes. In accordance with the cost of the product, its durability, strength and performance differ. Based on this, investments in vapor barrier directly affect the state of the frame, interior decoration and insulation.

Dense polyethylene is best suited for arranging waterproofing. The film is soft, inexpensive, and easy to install. It should be borne in mind that in the cold it loses its qualities and collapses.

In a cold climate, it is advisable to use a modern roofing material (type of euro). The material is so reliable that it is guaranteed to serve the entire life of the building.

DIY construction of a pie wall of a frame house

The construction methodology for frame-type houses is almost the same, with the exception of the arrangement of interior and exterior decoration. In all cases, the initial stage is the installation of the lower harness, the erection of the frame and its fixation with the upper harness. Then, in places for windows and doors, transverse lintels are made.

The process of arranging the cake consists of the following stages:

- Laying of communications. It is necessary to run the wires into corrugated plastic or steel tubes with a rigid fixation to a solid base.

- Insulation laying. Mineral wool mats are inserted at the edge, the foam is glued on the sides, expanded clay is poured over the fence, the foam is evenly distributed over the cell closed on one side.

- Installation of vapor barrier. The films are nailed to the frame with staples, the joints of the strips are superimposed by 10-15 cm and glued. The smooth side is placed inside the house, and the rough side is placed outside.

- Fastening to plywood or chipboard framework. This is done so that their edges are located on the racks. Pre-holes are made in the plates for fasteners to prevent them from splitting when screwing.

- Fastening the lathing. This can be done on one or both sides, depending on the particular cladding chosen. If these are slats, they are carefully treated with a hydrophobic agent, antiseptic and flame retardant. Metal profiles are coated with an anti-corrosion agent.

- Installation of a rough or just finishing finish. The method is due to the peculiarities and rules of fastening the material.

In cold areas, it is customary to equip additional thermal insulation.It is placed in a crate and in turn is covered with a membrane fabric. If foam is used, gaps are left between the boards to allow air circulation.

When using siding, a frame is made of sufficient thickness to accommodate the self-tapping screws used to attach the panels. For such cases, wood slats or thick, waterproof plywood are better suited.

A separate issue is brick cladding. The best option is clinker tiles. The cladding is laid on a waterproof adhesive, but in the case of a frame structure, it is advisable to stop on models with fastening on profiles. Installation is carried out on wood boards with anchors or self-tapping screws.

Internal and external finishing

Since the wall cake is a collection of soft materials and hard boards, it needs a decorative finish. Indoors, a material is selected that is in harmony with the floor or ceiling. The most common options are imitation timber or plastered drywall. Sometimes a simpler and more budgetary solution is made - plywood, wallpaper or paint.

Outside, durable, waterproof, moisture-proof materials are installed. Used plastic siding, PVC panels or sandwich panels that combine the properties of insulation.