A metal profile pipe fencing is an economical and reliable option, suitable for a permanent home and a country house. To create such structures, products of a quadrangular section made of low-alloy steel are used. Making a fence from a profile pipe with your own hands will not be difficult even for a person who does not have special skills.

- Pros and cons of constructions from professional pipes

- Drawing preparation

- Required tools

- Preparatory work

- Dimensions and section of the profile

- Pipe weight

- Anti-corrosion treatment

- Number of support pipes

- The order of the main work

- Installation of foundation and support pillars

- Frame welding

- Installing sections

Pros and cons of constructions from professional pipes

Steel profile fencing has a beautiful appearance and good sunlight penetration, which makes it suitable for garden and vegetable gardens. The pipes used for it are distinguished by increased strength compared to products with the same wall thickness and diameter, but having a circular cross section.

In addition, such fences have the following advantages:

- room for design solutions - the ability to make an uneven top by combining pipes of different heights, decorate the fence with forging or carving;

- compatibility with different types of building materials;

- affordability of the price;

- reliability and durability, the ability to serve for several decades (but pipes must be periodically treated with an anti-corrosion compound).

The design does not hide the area from prying eyes. This can be corrected by covering the fence from the inside with a profiled sheet or polycarbonate. Another option is to plant climbing plants around the fence.

Drawing preparation

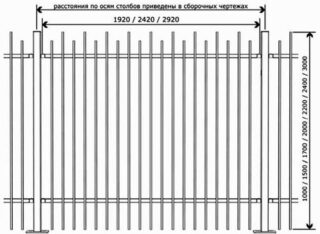

To make a fence from a professional pipe with your own hands, you must first make a drawing. You can take a ready-made example as a sample or design a structure yourself. The correct sketch should contain such parameters as the distance between the supports, the thickness of the unit of the metal profile, as well as the dimensions of individual elements.

If the structure is planned to be supplied with automation, the location of its location is marked on the drawing. Such gates require a greater amount of clearance between the leaves than those that can only be opened manually. If the structure is sheathed with corrugated sheet or galvanized steel, it is supplied with frame components.

Required tools

To make a fence from metal pipes with your own hands, you need to prepare profile elements and material for sheathing (if the project assumes the presence of the latter). For support pillars, pipes must have a larger cross-section (approximately 2 times) than for frame elements. Sometimes homeowners purchase ready-made sections. Decorative elements should not be too massive compared to the main part - this increases the load on the foundation.

You will also need fasteners - they can be self-tapping screws or special hinges. These elements can be used to attach the sash to the posts. It is also advisable to paint the structure with a special compound intended for steel that has not been galvanized. This will help prevent the development of corrosive processes.

Of the equipment, you will need a welding machine, as well as a grinder and an electric drill. In addition, tools are needed for measuring and controlling evenness: a corner, a building tape and a level. For finishing, you need a brush and a joint sander.

Preparatory work

It is necessary to correctly select the dimensions of the pipes and make calculations. Also, building materials must be treated with an anti-corrosion compound.

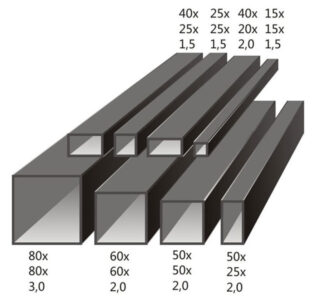

Dimensions and section of the profile

The professional pipes presented for sale have different dimensions. For supporting pillars, it is necessary to purchase large elements that have a minimum of 10 cm in diameter and a wall thickness of 5-8 mm. Other vertical posts can be 5-8 cm in diameter, transverse joists connecting elements horizontally - 3-5 cm. The cross-section of all components of the structure should be in the form of a square or rectangle. Round and oval profiles cannot be used. According to the production method, the use of seamless products is permissible, but welded cold-rolled products are the best option.

Pipe weight

After calculating the weight of the pipes, you can find out the total mass of the planned structure. This will allow you to understand which type of base will work best and the allowable span width.

To find out the specific gravity of tubes with a square cross-section per 1 running meter, you can use the formula: m = (x-t) * t * 0.0316where x and t - the side of the section and the wall thickness (in meters), respectively. For rectangular pipes, the formula will look like this: m = (x + y-2 * t) * t * 0.0158 (here x and at - the sides of the section).

Anti-corrosion treatment

Steel surfaces that are not protected with a zinc coating quickly begin to corrode and other destructive environmental influences. If you take care of the protection of pipes in time by applying special compounds, the fence will last for several decades.

In hardware stores, you can find a variety of zinc powder-containing paints and varnishes designed specifically for steel objects.

The pipes of the metal profile have an empty space inside, it is advisable to minimize the penetration of water into the interior so that the walls do not begin to collapse. To do this, you can purchase special plastic plugs that are suitable in size for the pipes used. Ornamental zinc caps can also be made to seal the voids in the tubing.

Number of support pipes

The number of supports is determined by the length of the site perimeter and from the selected distance between adjacent columns. If the weather in the area is windy, it is better to mount the racks close to each other (after 1.5-2 m). In regions with quieter conditions, you can increase this value to 2.5 m if the fence is not high.

The order of the main work

The installation of the fence begins with the creation of a foundation and the placement of support posts. Then the remaining elements are fastened in accordance with the diagram of the drawing.

Installation of foundation and support pillars

The type of foundation is chosen depending on the weight of the structure and the characteristics of the soil. For unstable soils and heavy fences, a pile foundation is suitable. Tape designs are also used.

Before arranging the foundation, the site is marked along the perimeter. The deepening of the supports into the soil is determined by the mark of its freezing. Typically, the indicators vary within 1-1.5 m. The mounting locations of the supports are measured strictly in accordance with the design data and the length of the sections. Added to this is 20 mm for the mountings. The diameter of the hole where the post will be placed must be 0.1 m larger than that of the unit of the metal profile. At the bottom of the finished ditch, a sand and crushed stone pillow 0.3 m high is organized and carefully rammed. After that, the support pillars are installed and filled with cement.

Frame welding

To weld the frame of the fence from the profile pipe, the elements of the profile are cut to the specified dimensions and faceted. The surface is sanded, after which the sectional frame is welded along the perimeter. After that, logs are installed - transverse and vertical. Then decorative details are welded. Seams are leveled and cleaned.

Installing sections

They can be mounted when the concrete gains strength - a month after pouring. When installing sections, their evenness is controlled by the level. Then the surface is degreased and painted.