The gable roof is the most popular structure used in private and commercial construction. Structures of this type combine reliability, strength, simplicity and functionality. The quite affordable cost of the project is also an important factor. The novice developer should take into account that the gable roof rafter system is its basis, which determines the shape, reliability and durability.

The device of the gable roof rafter system

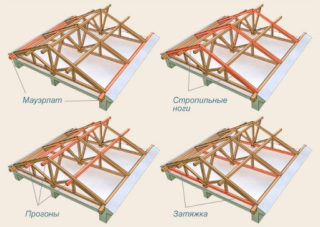

The rafter system has such a device:

- Mauerlat. Strong timber that is reinforced along load-bearing walls. Serves to evenly distribute the vertical load along the walls of the house and keep the roof from overturning by the wind.

- Rafter legs. They are slanting beams that form a triangular roof structure. Installed at intervals of 60-120 cm, depending on related factors.

- Sill. A powerful bar that fits between opposite sides of the Mauerlat. Designed to support intermediate elements and neutralize the expansion pressure of the rafters.

- Tightening. Tightens the bases of the rafter legs, preventing them from moving apart. It is used in hanging systems.

- Racks. Installed vertically to support the skate and transfer its weight to the walls of the house.

- Braces. Placed under the rafters in order to prevent them from sagging under the mass of cover, snow or workers on top.

- Lathing. It consists of several rows of slats nailed from above to the rafters. Serves as their screed and base for roofing material.

- Skate. A horizontally located central bar, to which the rafter legs and roof slopes are attached with the upper ends.

- Filly. They are used to create an overhang when the length of the structural elements of triangular trusses is insufficient.

There are several options for arranging the rafter system, each of which has its own distinctive properties, pros and cons.

Design features

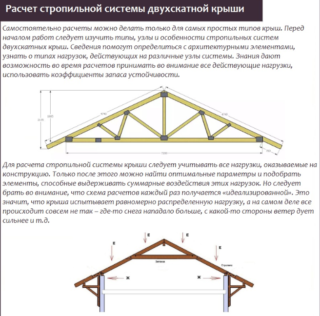

When calculating rafters for a gable roof, it is necessary to take into account the following factors:

- the strength of the wood species;

- bearing capacity of a bar of a certain section;

- the maximum level of snow cover in the region;

- climate map data regarding wind direction and strength;

- roof slope angle;

- weight per square meter of roofing material;

- weight of insulation, membrane film and waterproofing;

- ridge height above ground level;

- seismic activity of the area where construction is being carried out.

Between the Mauerlat and the floor slab, it is imperative to lay a layer of waterproofing to protect the wood from dampness. Fastening fragments of the frame should be done only with cuts, fixing each node additionally with pins or nails, plates or corners.

You can correctly calculate the step and section of the rafters using the tables and formulas set out in SNIP II-26-76. Online calculators, which are available on the websites of construction companies, allow to simplify the process somewhat. However, this allows you to get an approximate result with an error of up to 20%. It is better to spend time, collect and compare data, make a competent plan and drawing.

Types of gable roof truss systems

The following types of truss systems are used in construction:

- Forced. The lower edges of the rafters are rigidly attached to the Mauerlat or the upper rim of the wooden walls. From above, fastening is carried out on a ridge or a bar directly between each other into the castle. Such structures are spacer and non-spacer. The essence lies in the rigid contact of the roof and walls along the entire perimeter of the building.

- Hanging. Here, the triangular fragments are assembled, where the rafters are connected to a horizontally located tightening. The lower beam is connected to the Mauerlat or walls. The peculiarity of this type of frame is that it transfers only the vertical load to the house, since the stretching processes are dampened by the puff.

In the construction of houses in which the columns are the basis, the installation of structures of both types is carried out. The rafters, located at an angle, rest on supports, and the hanging ones are placed between them.

Installation and fastening of rafters

The builders have developed an excellent option - cuttings in the load-bearing beam. This is a small depression into which a similarly shaped protrusion of the adjacent fragment is inserted. From above, the joint is closed with steel fasteners. This method allows the system to effectively withstand tensile and pull-off loads.

Do-it-yourself installation of the rafter system

To install a roof frame, you need to have a minimum set of household tools and be able to use them.

- puncher;

- screwdriver;

- a hammer;

- level, tape measure;

- hacksaw or chainsaw;

- electric drill;

- paint brush;

- steel spatulas;

- cement and sand;

- fire retardant, antiseptic;

- waterproofing materials.

It is necessary to make the rafter system in the means of protecting the skin and respiratory organs. The assembly of the frame is carried out at a height, so you need to think over the safety issues of the builder and the people below. It is necessary to put up fences or hang up warning signs.

- Determination of such indicators as the thickness of the snow cover, wind speed and seismic activity.

- Derivation of the formula for calculating rafters, drawing up a structure diagram.

- Leveling the walls of the building using cement mortar, scaling or wooden battens.

- Laying the Mauerlat. Making a frame that gives it the ability to resist stretching.

- Marking and laying of beds.

- Basting of the installation points of the rafter legs.

- Sawing out fragments of the frame.

- Installation of waterproofing.

- Processing of wood from insects, decay and fire.

- Installing the bed.

- Placement of rafters in accordance with the markings, connection to the ridge or to each other.

- Installation of vertical elements.

- Installation of retaining racks.

- Arrangement of the lathing.

In conclusion, the assembly quality is checked and defects are eliminated.