The roof frame is the main part of the entire roof structure of a private house. This element bears the main load. The system must be able to withstand the weight of the roofing cake and outer covering, sediment build-up and wind loads. If the rules of technology are not followed during construction, the service life of the frame will be reduced significantly, it may begin to deform, and wooden elements will begin to deteriorate from moisture. You can assemble the structure yourself if you perform the work in accordance with the step-by-step instructions: this will save on the services of the installation masters.

Types of roof frames

The classification of structures is possible according to a number of parameters, including the structure (there are systems for single-slope, gable, multi-slope roofs), the angle of inclination, the type of rafters and other factors. The most popular division is by material.

Wooden

The roof of a frame house, brick, block or monolithic private building, the height of which does not exceed 2-3 floors, is often equipped with a wooden rafter system. The same designs are used in the construction of garden houses, gazebos, guest houses, baths and saunas. Wood is a fairly light material that combines an environmentally friendly composition with good strength and ease of installation.

For the manufacture of the structure, boards with a thickness of 5 cm are used, bars with a square section of 10 x 10 or 15 x 15 cm.When arranging a roof frame made of wood, it is important to carry out preliminary processing by covering the surface with a fire retardant compound and varnish or paint to protect against moisture, the formation of fungus and mold ...

It is not recommended to install wooden rafters if the house has an increased length: such elements will bend strongly under their own weight.

Metallic

If you plan to make a roof with increased slopes or use too heavy material for the outer covering (for example, natural tiles), it is advisable to choose metal structures. Distinctive features of such structures:

- increased bearing capacity;

- resistance to temperature extremes, flame;

- when galvanized or painted with special polymeric substances, the structure is resistant to moisture and condensation;

- service life exceeds 60-70 years.

Roof frames made of a profile pipe are installed if the bearing characteristics of the foundation allow the use of heavy materials, otherwise the building will sag strongly.

Reinforced concrete

This type of frame is made of floor slabs with standardized dimensions and weight. These structures are used in multi-storey buildings, industrial and commercial stationary buildings. Reinforced concrete frame structures are suitable for arranging non-ventilated roofs without a roof; the top covering can be made of roll material - roofing material, soft roofing, etc.

Roof frame device

The rafter system includes several components:

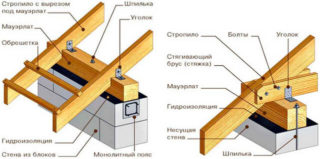

- Mauerlat. This is a rafter, which is laid over the upper brick, block row or crown of the building along the perimeter. For the production, mainly raw materials of coniferous wood (pine, spruce, larch) are used.Anchor bolts or special metal studs are used for fastening.

- Sill. This is a beam that is laid on internal partitions, in contrast to the Mauerlat, which is located on the load-bearing external walls. The central posts are mounted on the bed, which serve as supporting elements for the ridge.

- Racks. These are the vertical elements of the rafter system for the central part of the frame legs and the ridge girder.

- Rafters. They are located at an angle to the ridge girder from the Mauerlat and the bed. If the under-roof space is planned to be equipped for storing tools or to make an attic floor there, the rafter legs are installed at an increased angle.

- Crossbar with ties. These are horizontal frame parts that serve to tighten the legs of the structure. The crossbar is placed directly under the ridge, the element is characterized by increased thickness and strength.

- Braces. Required to protect the rafters from deformation due to their high weight.

The scheme of the simplest structures often includes only a Mauerlat, rafters and a ridge girder. The more complex the roof configuration, the more elements the frame contains.

Selection of the type of rafter system

- layered - the frame rests on both the outer and inner load-bearing parts of the house);

- hanging - there is only one fulcrum - at the junction with the Mauerlat.

The second type of rafters is intended for buildings without solid walls inside the box. Such a roof is gable, has the shape of an equilateral triangle, therefore it does not require additional stabilization. The choice of the type of rafters is also made taking into account the complexity of the roof structure, the presence of an attic, dimensions and other factors.

Materials and tools

To erect a roof in a frame house, brick or block structure, you will need:

- wooden beam for rafters with a section of 150 x 50 mm;

- bar 100 x 100 mm for Mauerlat;

- boards 50 mm thick for lathing;

- fasteners (screws, anchor bolts, etc.).

Of the tools when assembling a wooden structure you will need:

- a hammer;

- saw on wood;

- electric drill;

- screwdriver;

- ax;

- construction plumb line or tape measure.

If the frame is metal, you will need to purchase reinforced corners 50 x 50 mm, metal screws. You also need to purchase or rent a welding machine and buy consumables for the equipment.

DIY roof frame installation

When assembling a structure, it is important to perform the steps in stages:

- Laying the Mauerlat. A waterproofing layer is preliminarily laid between the wall and the timber, studs embedded in the upper crown or a row of bricks / block, or anchors are used for fastening. It is advisable to treat the Mauerlat bar itself with fire retardants and antifungal agents.

- Installation of the bed. It is fixed in the same way as the Mauerlat.

- Racks are installed on the bed and temporary supports are placed so that the elements do not warp. The step between the posts is 120-150 cm.

- Girder laying. It is located on top and serves to tie the vertical frame parts. Rafters will be mounted to the run.

- Installation of rafter legs. Fastening of one part is performed to the Mauerlat, and the opposite to the girder.

- Fastening the lathing. It is to it that the roofing cake will be attached on the inside and the topcoat on the outside. The lathing is attached to self-tapping screws (less often - nails) perpendicular to the rafters. The pitch is 50-70 cm, depending on the choice of roofing, in some cases it can be reduced.

Arrangement of the frame can be carried out only after the final shrinkage of the walls, if they are assembled from a log or bar.

Design features

Before starting the design, it is important to consider a number of factors:

- climatic conditions in a particular region;

- wind load level;

- the purpose of the roof space;

- type of outer coating, weight and size;

- financial opportunities.

In the absence of skills, it is better to entrust the task of building a roof to professionals. Understanding the technology will allow you to control the correctness of the implementation.