In the construction of the porch there is a platform and steps along which a person climbs to the front door. The structure is framed with handrails, handrails, and comfortable ramps are made for the descent of heavy things. The steps for the porch are of various shapes, widths and heights, while being guided by the standard dimensions. If the porch is connected to an open veranda, the ascent can be shared to the terrace seating area and entrance.

Porch steps

The steps go up to the site, so they choose the correct slope of the stairs. If a steep descent is obtained, the common stepped ladder is lengthened in order to increase the number of elements and reduce the height of the riser. Railings are installed starting from three steps, and with a smaller number of them, the fence plays the role of decoration.

Calculation of dimensional criteria

Recommended sizes:

- element width 25 - 30 cm;

- the optimal slope of the stairs is 30 °, but a range of 25 - 45 ° is allowed;

- at a lower slope, the step ladder is changed with a ramp;

- the width of the march should not be less than 70 cm for a person to pass comfortably.

Calculation example. The base is raised 2 m above the ground, and the norm for a comfortable leg stroke is 12 - 20 cm. Divide 200 cm by the average value (16 cm), get 12.5 steps, take 12 pieces.

Materials for the manufacture of steps

Metal

Sometimes the metal is sewn up with wood or other material to reduce walking noise. Inclined girders are also made of steel, ready-made step structures are attached to them by welding. There are options for treads made of non-ferrous metal, such as copper or aluminum. Such parts are decorative, they are attached to the stringers with bolts and nuts.

Wood

The material is capable of getting wet, which reduces the service life, therefore it is protected from moisture. Parts are impregnated with oils based on minerals, treated with bituminous compounds, covered with hot linseed oil. After installation, they are painted with resistant paints and varnishes.

Concrete

Reinforced concrete stairs are of two types:

- prefabricated (kosour, type-setting steps);

- monolithic (made in removable formwork).

Concrete one-piece structures can be made of various shapes, for this they provide formwork from boards or bending plywood, plastic. A heavy structure requires a foundation with a height of 0.8 - 0.1 m in the form of a rammed bed of crushed stone or gravel.

For reinforcement, rods with a corrugated or smooth surface with a diameter of 8 - 16 mm are used. They are installed so that the frame of the steps is connected to the frame of the platform and inclined girders.

Brick or tile

Tiles according to the instructions are used for outdoor use, they take clinker or porcelain stoneware. A prerequisite for choosing a tile to make outdoor steps for a porch is a rough or corrugated surface. This will prevent slipping due to icing or snow adhesion.

Types of steps for the porch

The shape of the staircase is taken taking into account the exterior of the building, functionality and the wishes of the owner. A large porch with massive steps will emphasize the greatness of the building, and small marches are placed in small temporary huts, summer cottages, small houses.

In order not to make repairs every year, you need to choose the right design of the steps and their shape. Prefabricated elements that are manufactured at the factory are often installed. In this case, you do not need to wait for the concrete to gain strength, you can start finishing immediately after installation.

The steps are mounted on a metal stringer and on reinforced concrete girders, while distinguishing the structure of the porch with or without frieze steps.

By the method of docking

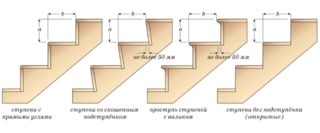

There are ways to connect to a run:

- rectangular;

- roller-like;

- with an oblique riser;

- without risers.

The upper and lower steps of the frieze group become part of the base and upper platform of the porch, their width is taken into account when calculating the total length of the entire march.

By form

Rectangular steps are more common. This shape is convenient for installation, does not require additional attachment points for stability. They cannot be installed in the design of screw types of marches. When arranging elements with right angles, there is no overconsumption of wood, metal, tiles.

The round, radial shape becomes convenient if the staircase requires access from several sides of the house. For them, turning marches are arranged, where only one side is rounded. Trapezoidal steps are obtained when installing a spiral staircase, while their support on one side can be on a separate rack.

DIY construction features

Before the erection of steps for the entrance, a general sketch is made with the platform or adjacent structures, if any. In the drawing, the dimensions of the steps are put down for counting materials. Skills of working with wood, concrete mix, tiles and the ability to use a welding machine are required.

First, stringers are installed, then individual steps are made and fastened. An electric heating system is installed under the facing tiles so that snow melts on the treads and ice does not form. To protect against precipitation, a canopy is mounted over the steps along the width of the stairs or larger in size.

After installing the inclined girder, they begin to fasten the steps from below. First, a riser is mounted, and a step is installed on it. The railing is placed after the end of the construction of the staircase with the platform.