The gate is welded from square pipes, which are made of stainless steel, carbon steel with a galvanized coating. Structures are single-leaf and double-leaf, sliding or sliding. The owners try to assemble the gates from a profile pipe with their own hands in order to emphasize the individuality of the structure, to use a beautiful and unique design.

Profile tube as material for the gate

The production billet is a round tube, which is formed by cold deformation by rolling on rollers. Then the products are subjected to heat treatment to remove the internal mechanical forces that occur during molding. Products obtained by this method are not designed for heavy loads, they are not used in frame construction, but are used for the manufacture of awnings, gazebos, railings, gates, fences and other small forms in a private yard.

Positive material characteristics:

- low cost of production;

- low weight of finished products;

- easy processing;

- attractive appearance of structures after finishing;

- durability;

- convenience in joining segments, attaching loops, screwing in self-tapping screws.

Disadvantages are manifested in the fact that if the manufacturing technology is not followed, places arise where the outer layer is broken, rust appears, then corrosion. Threaded and bolted joints loosen over time, so a welding machine is used. The structure requires a primer and painting to get a beautiful look, additionally to protect the metal from destruction.

How to choose the right profile pipe

The type of metal and the concentration of alloying components affect the strength of rolled products, resistance to corrosion damage. The supporting elements are made of high-strength iron with a high alloying percentage. Strength depends on the thickness of the metal, therefore, pipes with an outer shell thickness in the range of 1.5 - 3 mm are used for entrance structures and fences.

There are round pipes, oval, rectangular products, square and triangular profiles are used. To organize the passage, the second and third options are used, since a flat plane is required for ease of assembly.

Recommendations for the selection of profiles:

- for dug-in pillars, a square of 100 x 100 mm is used, rectangles are taken 120 x 60, the wall thickness is 3 mm;

- the frame is boiled from pipes 40 x 40, 40 x 20, 50 x 50 mm with a shell thickness of 2 mm;

- for stiffeners, struts, a section of 20 x 20 x 1.5 mm is used.

You can use pipe cuttings left over from the manufacture of other structures, if they fit in such a way that they do not need to be welded lengthwise. Such joints weaken the strength of the door frame. Hot-rolled seamless pipes are rarely used for gates, since they have increased bearing capacity and are expensive.

Preparation for work

You can weld a gate from a professional pipe with your own hands, if you correctly find the dimensions of the structure in height, width, choose the opening option.

The width of the gateway depends on the size of the vehicle.For a passenger car, which has a width of 1.5 - 1.7 m, a size of 2.5 m is required. If there are constrained circumstances, the gate provides for 2.0 - 2.1 m, but the driver's caution is required when entering and exiting. The sizes of the cars are different, therefore, they are guided by the fact that at least 40 - 50 cm remains on the sides.

It is better to calculate the structure for the passage of freight transport. In rural areas, this can be a tractor, a car with a trailer. The width of such machines fluctuates at the level of two meters. For trucks, travel is provided for 3 m, this is the minimum, the maximum can be 3.5 - 4.0 m.

The entrance to the gate is sometimes at an angle, or there are structures and trees on the way. Then the width is increased to 5 m or more, depending on the situation. As a standard, the height is taken at the level of the fence, but there are options with lowering the canvases compared to the fence, or, conversely, raising it. Opening in swing products is done inward, so as not to interfere with the passage and travel along the street.

Drawing construction

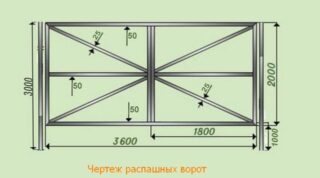

The detailed drawing shows:

- dimensions of workpieces when cutting;

- welding scheme for transverse and longitudinal frame elements;

- location of transverse stiffeners;

- installation areas for corner and diagonal braces.

Looking at the sketch on a scale, you can see the proportions of the product, make adjustments in time. A gate is often made in the canvas so as not to open a large sash when people pass. The drawing shows the location of the wicket frame, the attachment points of the transverse elements of the frame, the dimensions of the opening part. Loop fixation points and constipation points are also provided.

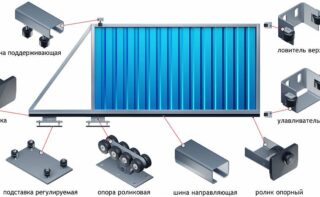

For sliding options, the drawing shows the plan of the base for the longitudinal guides for the rollers or the installation location of the upper rails. The drawing of the automatic gate shows the installation areas of the automatic opening system.

What is important to know about self-made gates

The easiest way is to make a swing option. The structure consists of support pillars, gate frame, leaf frames and inner filling. For opening, awnings are provided, which are one-sided or pendulum (swing in different directions). The gates are locked, bolts are additionally placed, there is also a fixing latch at the bottom, which rests against the roadbed (they dig in a sleeve).

For flawless performance, the following aspects are important:

- ergonomic and attractive design;

- information drawing of the structure with the correct dimensions;

- profile pipe suitable for power;

- high-quality opening fittings.

Sliding structures are popular with the public, since they do not require space in front and behind them for opening. The doors are made in a frame, struts and struts are installed for rigidity. Sliding gates do not react to snow drifts, the owner does not need to clear snow to open. The console versions do not have an upper limiter, so cars of any height can enter.

How to weld a fence with your own hands

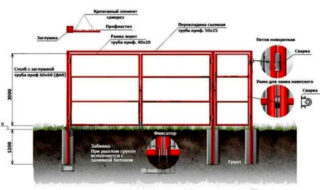

Before fabrication, the posts must be installed in order to obtain the exact dimensions for welding the frame. They are made from metal or asbestos-cement pipes, bricks, concrete, wood. It is better to work with two people, so that it is convenient to fix the racks without distortions.

Step-by-step installation guide:

- dig a hole 70-100 cm deep (depending on the severity of the valves);

- a layer of sand is poured on the bottom, then, crushed stone, 10 and 15 cm, respectively;

- the bedding is tamped and spilled with water;

- put a support, adjust it vertically using a level or plumb line;

- fixed in the ground with spacers;

- concrete is prepared, for this they mix cement, sand, crushed stone, the last material can be replaced with screenings, slag, expanded clay or finely broken brick;

- concreting a hole in the ground around the post.

The concrete hardens on the second day, but gains 100% of the fortress on the 28th day. Canvases can be mounted a week after concreting.

Required tools, fixtures and materials

To expose the racks and hinges of the gate, take a building level or laser, tape measure, core and pencil.

Other required tools:

- an electric welding machine, consumable components are needed for it;

- drill, screwdriver, Phillips screwdriver;

- grinder with a disc for cleaning and leveling welded seams;

- pliers, hammer, metal brush, coarse emery;

- bayonet shovel, ax, scrap for earth excavation;

- a concrete mixer or a metal trough for preparing concrete, a shovel;

- painting tool (roller with a brush or spray gun).

For the frame, a professional pipe of the required shape and section is used, the segments for the stiffeners are calculated. The filling material is acquired so that there are fewer connecting seams on the surface of the flaps. They buy ready-made hinges, preferably with a galvanized layer; they choose mechanical, electrical or electronic locks.

Sequence of work

The pipes are cut into pieces of the required size in accordance with the drawing. It is taken into account that corner joints are welded at 45 °, and for T-shaped joints, the profile is cut at right angles.

Stage-by-stage production:

- prepared parts are cleaned of rust using sandpaper and a metal brush;

- welding of frames is carried out in a horizontal position on level ground, or goats, tables are set up according to level;

- first, the frame is welded, then the crossbars, diagonal or angular struts are set;

- knock down the scale from the welded seams, clean them with a grinder to evenness, primer, paint;

- insert and fasten the sash sheathing;

- hinges are fixed in the necessary places, canvases are hung;

- weld on locks, bolts;

- close the end holes of the pipes with plugs, weld or seal with a sealant.

For sliding gates, a concrete base is made, in which guide profiles for rolling rollers are fixed. The wires for electrical control are led out into the pits when concreting the pillars, and hidden in pipes protruding above the surface.

The better to sheathe the frame of the gate

The material is chosen at the request of the owner in accordance with his financial capabilities.

Sash filling is possible:

- Solid. Such a canvas is not visible from the outside. For stitching, boards, corrugated boarding, siding, sandwich panels and other materials are used.

- Transparent and translucent. The doors are filled with polycarbonate, solid panels or cellular ones are installed. The sheets come in different colors, but through them you can see the silhouettes inside the courtyard.

- Lattice. For filling, a metal rod 6 - 8 mm thick with a smooth or corrugated surface is taken. The lattice is made so that squares or elongated rhombuses are obtained. The material is also a wooden lath.

- Openwork, forged. An expensive option, since forging costs much more in the workshops than a simple welded grating. But such canvases have an original pattern that other owners do not have on the street or in the city.

The last two options are referred to as translucent types of gates, since the gaps between the elements allow you to see what is happening in the courtyard, although visibility is reduced by half from a distance.