The frame construction method is the simplest and fastest. The structure is light, strong enough, insulated in accordance with climatic conditions and finished to the taste of the owner.

Varieties of frame houses

After the construction of the frame, the cavities between the posts are filled with material. By the type of this material, there are 2 types of buildings:

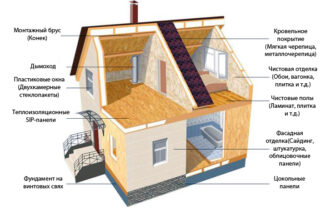

- Frame - a wooden or metal frame is sheathed with sandwich panels. These are relatively small multi-layer slabs. The panel includes insulation, waterproofing and OSB backing. Then the walls are finished from the inside and outside with a suitable material. The advantage of this option is the ability to vary the structure of the building as you wish.

- Frame-panel board - sheathed with panel panels. These boards are only manufactured in an industrial environment and are not assembled on a construction site. Shields include cladding made of chipboard, gypsum board, polished boards. Communication is often placed here. Panels with window and door openings are also delivered to the site in finished form. The assembly of such a building resembles a constructor and is completed in a week. Uneven floors, walls, oblique openings are excluded.

The frame of the building is usually constructed from timber of the required thickness. You can assemble the base from a metal profile. The frame is very light, but it does not differ in high strength. This technology is used to build houses no higher than 2 floors.

Features of frame houses

The technology of construction of timber frame houses provides a number of advantages:

- high speed of installation - the construction of the foundation takes most of the time. The construction of walls and ceilings is very fast;

- the structure is light, so the foundation is required the simplest;

- assembly is carried out without heavy equipment, which reduces the cost of construction;

- technology allows you to diversify typical projects with interesting architectural details;

- frame buildings with sandwich panels are distinguished by the highest heat-saving properties, heating costs are minimal;

- facade cladding is performed with any materials, but not heavy ones.

The cons are as follows:

- it is necessary to install forced ventilation, otherwise it will be stuffy;

- low sound insulation;

- short service life - about 20 years.

The cost of erecting a frame building is 30% less than building a brick building.

Foundation selection

- Columnar foundation - pillars made of concrete or brick on which the building rests. It can be buried or shallow. It is used at low groundwater levels. Its construction takes a minimum of time, and with a small depth, it allows you to do without the use of technology.

- Pile-screw - erected on soft ground, like a swampy, heaving, in low-lying areas. Metal piles are usually screwed, screwed into the soil and connected with a bottom strap. It is very economical: there is no need to dig trenches for piles, and the area for the house does not need to be leveled.

- Tape - being built for 2- or 3-storey houses. For a frame building, it is often quite shallow, with a low level of groundwater.For such a foundation, you need to dig a trench about 1 m deep and put the formwork. The base is made of concrete, so the construction of the walls can be started only after the material has completely set - after 21 days.

It is extremely rare for a monolithic slab foundation to be made for a frame construction. Usually this has to be done if the soils are very unstable, prone to strong heaving. This option increases the cost of construction.

Performance categories

This method allows you to change the project, suspend construction or continue it at almost any stage. It is also possible to build 2 or 3 floors a few years after the construction of a one-story building.

Another method - the construction of a frame with through racks - is used less often in private construction. It is more complicated, it involves the support of the racks on the strapping lower beams and load-bearing walls. In this case, the frame is erected to the full height of a 1-, 2- or 3-storey building.

This method is often called "German". The assembly of ready-made building blocks and racks significantly speeds up installation. On the other hand, it ensures absolute accuracy and absence of inconsistencies.

Warming and vapor barrier

The floor and ceiling must be insulated separately. The choice is the same. However, basalt and mineral wool is preferable as it is fireproof.

Vapor barrier in a frame house is carried out only with the help of special membrane films.

Materials for outdoor decoration

The construction technology of any frame house allows you to use a variety of materials for decoration:

- Painted board or lining is an environmentally friendly, beautiful, affordable material. A coat of primer and paint replaces the rain and frost finish.

- Vinyl siding - lightweight plastic slats with different structures, colored or imitating wood. Siding installation is very fast.

- Fiber cement - strong, fireproof, durable, not afraid of fungi or rust. In addition, concrete siding dampens noise, which is important for a frame building.

- Plaster - creates a protective vapor-permeable layer, smooth or textured. However, under the plaster, the walls need to be sheathed additionally with foam plates.

Heavier material such as clinker tiles can also be used. But it is worth considering that the service life of the cladding is longer than the service life of the building.

Construction stages

- Construction begins with the construction of a foundation: pile, columnar or tape.

- Tie the pillars of the foundation. Connect the timber to a half-tree.

- In the base heads and beams, holes are drilled for vertical posts. They make a rough floor - on logs or on the ground. At this stage, they are preparing for the laying of communications.

- They assemble the frames for the walls from boards and beams - for bolts and pins. They mount window and door openings.

- The finished structures are fixed to the lower beam.

- Equip the upper harness.

- Walls are sheathed with sandwich panels or shields. After sheathing, internal partitions are installed inside the building.

- Sew up the ceiling and build a roof. If the cottage is two-storey, start building 2 floors.

Frame technology allows you to build a comfortable and spacious house in a matter of months.Its construction will cost 25-30% cheaper, and in terms of appearance and performance, such a building is not inferior to a brick one.