High-quality and relatively inexpensive material with good technical indicators is used for roofing private houses, public and industrial facilities. The soft roof has thermal insulation properties, sound insulation characteristics, does not lend itself to corrosion and the spread of fungus. On the front side, a layer of mineral granules or a protective film is applied, so that the material better withstands the negative effects of the atmosphere.

Soft roof production technology

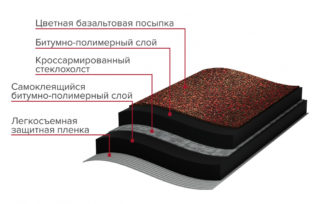

The material is produced on the basis of a fiberglass or polyvinyl chloride membrane impregnated with bitumen compositions to increase moisture resistance. The complex structure with surface dressing contributes to an increase in frost resistance, a decrease in fragility and an increase in strength. The material is laid on roofs with a slope of no more than 25 °. The material is chosen for covering large areas when other types are costly.

Installation technology involves several stages:

- surface preparation, cleaning, installation of solid or slatted lathing;

- arrangement of a ventilation space or an exhaust system for air circulation;

- flooring of rolls or piece elements on a wooden, cement, concrete base.

If the roof is glued directly to the slabs or screed, the area is leveled with mortar and primed. The day before the start of work, the rolls are rolled out and left to disappear waviness.

The solid base is made of moisture-resistant plywood, chipboard with wax impregnation. The sheets form a perfectly flat support of sufficient strength, along which workers move when laying rolls. The base is fastened with self-tapping screws, screwed into the chipboard immediately, and a hole of a smaller diameter is made in the plywood before installing the screw.

An edged board is used, which costs less than particle boards and plywood. The elements are easily sawn, processed, they are fixed to the rafters with nails, they are attached to concrete with dowels with self-tapping screws.

Planks are installed with technical slots of 3 - 5 mm to compensate for expansion from heat and cold. Large gaps will cause soft material to settle, but if not, the base elements will bulge.

Varieties of materials

Previously, the material was presented on the construction market in several varieties, among them there was roofing material of two or three types and roofing felt. Roofing paper is thick paper impregnated with resin.

Manufacturers have expanded the range of flexible roofing:

- roll roofing;

- polymer coating;

- roofing liquid mastics;

- bituminous piece tile.

Additives in the composition of the mastic increase frost resistance and resistance to ultraviolet light, therefore soft coatings can withstand temperatures from -50 ° C to + 120 ° C. An adhesive mixture is applied to the inner surface of the strips for attachment to the base.

Roll roofing

This variety is used to cover large rooftops of shops, sports facilities, hangars and factory halls. In private housing construction it is rarely used. It is sold rolled into rolls 1 m wide and 15 - 20 m long. A square of material weighs 6 - 12 kg, the difference depends on the number of layers and the type of the main canvas.Modern roll materials are developed on the basis of the old roofing material, but with improved qualities.

Several types of soft roofs are produced:

- bituminous coating;

- bitumen-polymer structure;

- polymer material.

High-quality flooring is created by melting in 2 - 3 layers. The work uses gas burners or units based on liquid fuel. The canvas is heated with a tool, the material melts and sticks to the base. The work requires experience, since you need to carefully direct the stream so that the roll material does not catch fire.

Soft rolls are laid on different types of base: they are melted on flat slate, metal, concrete, old roll coating during repair, wood. The disadvantage of such a layer is that you need to follow the technology so as not to violate the external insulation. Correctly installed flooring will last up to 30 years and longer.

Bituminous shingles

Outwardly attractive material is presented in a wide range of colors with imitation of different textures. Calibrated options with soft transitions between dark and light shades of the same color scheme look spectacular. The elements are produced in the form of plates (shingles), which are divided into several petals. The surface of the plates is protected with mineral or plastic dressing.

Bituminous flooring creates the appearance of a natural tile, thanks to the different shapes of the petals:

- rectangular;

- rhombic;

- hex.

The elements are mounted simply, for this they peel off the film from the bottom side, press the material against the base, and additionally pierce it with nails. The last fastening is used only in the case of a steep slope; in other cases, nails are not used, there is enough adhesive.

The plus is that the flexibility of the material allows it to be used on roofs of a semicircular, arched shape.

Bituminous shingles do not deteriorate from temperature changes and water, they resist frost and sunlight. Each sheet has an adhesive strip for pre-fixing when mapping a tile pattern.

Roofing mastic

The material is an artificial composition of organic binders with mineral fillers of various sizes, into which additives are added to improve the properties. Mastics are used for the device directly on the roofing surface or used as a waterproofing, vapor barrier, anticorrosive layer in other types of roofing systems.

According to the method of application, varieties are distinguished:

- Hot types are welded with preheating. For bituminous resins, a temperature of + 160 ° C is recommended, and tar is heated to + 130 ° C.

- Cold mixtures are diluted with kerosene, white spirit, solvent. They are applied without heating, mounted at a temperature of at least + 5 ° C. If the temperature is below the specified value, but above 0 ° C, then the composition is heated to +60 - + 70 ° C.

In some types, you need to add a hardener to harden. After application, the diluted dispersed mixtures harden, resulting in a smooth plane. Bitumen, tar, rubber-bitumen, polymer resins are produced.

Polymer membrane

A soft roof made of such material is more expensive than a roll, bitumen and mastic coating. As a result of laying, a one-piece monolithic flooring is obtained, practically without joints. The membrane itself is flexible and tear resistant.

Several types of polymer coating:

- Rubber diffusers. Cheaper than other membranes, they contain rubber. The strips remain pliable over a long period of time, but are susceptible to water leakage at the seams. They are glued to the surface using the cold method.

- PVC membranes of various colors. The joints of the flooring are connected by welding, obtaining reliable joints. The disadvantage is that the coating will fade over time under the influence of rays.

- TPO membranes.Reinforced types with glass fibers are fixed by heating the lower part of the strip, connected by welding. An expensive material, less flexible than other polymer coatings.

PVC membranes are used on flat and flat roofs. The soft roof from the overlaid views from above is pressed down with a crushed stone or gravel ballast layer 20 - 30 mm thick.

Which is better, a soft roof or metal tile

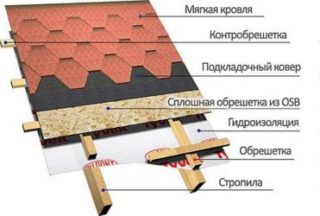

The step of the lathing for a metal profile depends on the slope, wave height, and roll materials require a solid base. A solid support is more expensive, but additionally creates sound insulation, reduces heat loss and increases the stability of the roof frame.

A square of metal tile weighs 5 - 12 kg, and a piece of soft roofing of the same square has a mass of 8 - 15 kg. The weight of the coatings is almost the same. Manufacturers guarantee the duration of the service life of metal tiles and soft roofs with a 30-year interval. Both coatings actually last longer.

With regard to fire hazard, bituminous materials lose, since they ignite at a temperature of + 110 ° C, and profiled metal has a higher threshold.

The sound insulation of roll roofing significantly exceeds the characteristics of stamped sheets and does not require a protective layer against noise.

For metal tiles, it is mandatory to install snow retention elements on slopes, and for a soft coating with coarse dressing, such systems are only recommended to be installed.

Both materials are distinguished by their beautiful appearance.

Advantages and disadvantages of a soft roof

Different types of soft roofing have their own qualities, but there are benefits for all categories. One of them is noiselessness and waterproofness. The materials do not require the installation of a waterproofing layer, since they themselves have similar characteristics.

Positive traits:

- no static electricity is generated on the surface;

- elastic coating;

- there is no wind sail;

- the ability to do it yourself;

- not subject to decay, contamination by fungi and microorganisms.

The disadvantage of soft roof tiles is that it is not always possible to make tight joints between the elements. This threatens with water leakage. Mechanical shocks, falling objects lead to ruptures.

Features of installation and repair

Before laying the covering, a lining carpet is placed, which additionally levels the base. It is laid over the entire area without gaps, with an overlap. Fasteners are made depending on the type of floor material. After that, the end and cornice strips of metal are mounted, nailing in a zigzag pattern.

The end strips are rolled out in the appropriate places and nailed. Tiled elements are laid out for selection by shade. Rolls are rolled along the length of the overhang at a distance of 2 cm from the edge. Subsequent strips are placed end-to-end, fixed by welding or nails perpendicular to the base.

The upper elements are staggered. A soft carpet is cut at the edges of the slopes with a knife and additionally glued with mastic. In the valley area, the shingles and membrane are fixed last, warming up the edges and placing a rigid sheet under the shingles so as not to burn the material.

Renovation work

They share the ongoing restoration, emergency and overhaul of the bituminous carpet. Small cracks are sealed with resin, a piece of polymer material is glued to the problem area, and covered with mastic on top.

If the seams have risen, do the following work:

- raise the edges;

- dry the bearing area with a burner;

- liquid bitumen is spread on a dry surface;

- the edges are pressed against the base, covered with resin on top.

During major repairs, the old carpet is completely removed, the surface is leveled with a screed. The layers of vapor barrier, insulation are changed, and a new soft coating is laid on top.