Frame half-timbered houses were built by peasants in the central and northern part of Europe in the X-XI century. The structure is a steel or wooden frame formed by a system of horizontal and vertical bars. The gaps between the elements of the frame of the half-timbered house were laid with adobe, bricks, stones. The structural details of the house were visible on the front side, and the internal structure of the building was judged from the ends of the beams.

- The history of the technology of half-timbered houses

- Differences between a modern half-timbered house and a classic one

- Advantages and disadvantages

- House assembly methods using half-timbered technology

- Long post method

- Short post method

- Features of the structure of half-timbered houses with their own hands

The history of the technology of half-timbered houses

Building techniques were adopted and reinterpreted by the Romans in the territories of the Gauls and Franks, which they conquered. Since then, they began to build a wooden frame, the gaps were laid with stones on mortar. They deliberately allocated vertical bars, struts and crossbars in the area of the outer wall. As a result, the frame of the natural dark wood color remained, and the masonry was painted with white lime.

The supporting frame was made of wood, since a forest grew around and there were clay deposits. The disadvantage was felt in relation to the building stone, so it was expensive. In Saxony and the south of England, builders competed to create an external pattern on the surface of the walls.

Gradually, the technology finds application in towns and cities in the Netherlands, Moravia, Prussia, Czech Republic, France. Wealthy homeowners laid out the frame space with carved wood slabs. The method of construction was called post-beam, while any structures of vertical and horizontal elements were called half-timbered.

The technology was improved, brick and stone supports for the posts began to be used to avoid rotting from soil moisture. The beams, crossbeams and struts have a rectangular cross-section, which has led to hardening of the joints. The hallmark of the style is the decorativeness of the facade and other walls.

The combination of dark elements and light fill gives the building a festive look.

In England, frame racks were placed vertically, and the Swiss and Germans placed them at corners. The combination of the skills of specialists from different countries made it possible to diversify the facades of buildings, find new technologies.

Differences between a modern half-timbered house and a classic one

A popular aggregate of yesteryear was adobe - clay with reed stalks or straw. To prevent the material from falling out of the wall, a base of branches was woven under it, then inserted into the selected grooves on the surface of the frame elements. The clay dried up, cracks appeared, they were filled with a mixture of wool and lime. Modern methods of sealing a half-timbered house involve the use of putty.

Modern and old style differ in details:

- The surface of the adobe was treated with a layer of lime flush with the racks, and painted. In modern conditions, cement-based putty is used for external facade work, and acrylic paint with modifiers is taken. Instead of clay adobe, simple or figured masonry is performed.

- Previously, protrusions were provided on the facade, but the increase in housing area was insignificant. Such a structure made it possible to protect the wooden frame from moisture flowing from the roof. She fell on the ground near the house or on the blind area.Modern methods make it possible to arrange an organized drainage from the roof, while the protrusions on the facade have passed into the category of small balconies, bay windows.

- In the old days, a brick was attached to the elements of the frame with the help of a triangular strip, which was then fixed to the surface of the frame. In the final brick, a sample was made for the lath. In a modern frame, steel anchors are installed for such purposes, and reinforcement of the rows is performed every 3 to 4 rows.

Modern methods of building houses have retained the half-timbered frame, but expanded the list of filling materials. The space between the racks, beams and struts is laid with a foam block, aerated block, brick, using innovative building materials. For the frame, they began to use metal instead of wood.

Advantages and disadvantages

Frame-frame construction allows the construction of reliable structures with stable characteristics, while the construction time is reduced. The method is recognized as economical, since the costs of wood and the cost of purchasing materials are minimized.

Advantages of half-timbered technology:

- tangible energy efficiency of a half-timbered house, while heat consumption is reduced, and energy is spent rationally;

- comfortable climate inside a half-timbered house, natural materials are able to regulate humidity and temperature in rooms;

- long service life of the building, thanks to a well-thought-out structural part;

- low cost of costs for building needs during the operational period;

- all parts of the house are subject to repair, the frame almost does not shrink;

- there is no difficulty in wiring communications.

Many half-timbered houses have stood in Germany for more than 200 years under conditions of correct use. Elegant buildings stand out from the rest of the buildings and look attractive. The ways of adaptation of a half-timbered house to different climatic situations have been developed. The plus is that an average-sized building can be built in 3 months.

The disadvantages include the susceptibility of wood to mold, fungus, bark beetles and the need for processing with special agents to increase the service life. The frame made of natural material can catch fire, so it is necessary to impregnate the elements with fire-fighting agents. The treatment is repeated regularly during operation. The building requires an insulating layer and a forced ventilation system.

House assembly methods using half-timbered technology

The foundation is made shallow, since the frame of the house is light and hard. The dimensions of the support base are chosen taking into account the soil characteristics in the region, taking into account the height of the ground liquid and the mark of freezing of the earth. The base is waterproofed from moisture and insulated with foam.

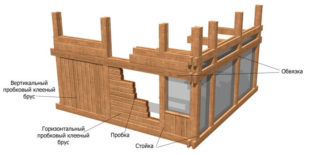

The frame racks are attached to the foundation with anchor bolts. Traditional logs and poles are replaced with high-tech polished and glued beams. Structural elements are joined with thorns, dowels. Many projects include steel corners and U-shaped fasteners for fixing.

A half-timbered house is equipped with the following methods:

- The infills between the posts and the beams do not carry any load, so there are many possibilities for redevelopment. The bookmark is made with various materials, more often cellular blocks, cement-particle panels are used.

- On the facade, the frame of the house is not closed, but is used as an architectural detail. Internal surfaces are finished in any way without restrictions in accordance with the design decision.

- Modern solutions for laying the spatial gaps of the frame are aimed at glass walls, when the transparent filling makes up about 60% of the wall area. Such options are being built in the southern regions, energy-saving glass and multi-chamber double-glazed windows are used.

The roof is made with large overhangs, gable.The design does not provide for the organization of an attic or attic. The coating material is a soft roof or metal tiles, galvanized metal.

Long post method

Buildings erected in this way provide for protruding steps from all sides of the house, starting from the second level. Buttresses are arranged simultaneously with the installation of floors between floors. The overlap runs are placed on the walls of the lower tier so that their edges protrude beyond the line of vertical fences by the size of the cross-section.

A load-bearing beam is placed at the ends, which serves as a support for the racks and struts of the wall of the next upper level. Buttress steps were often made only on the side of the front and back gables in order to save materials and speed up construction.

The half-timbered house is exposed to precipitation only from these sides, since they are the highest. In one-story or two-story buildings, there is no need to design protruding elements in the side parts of the house. Such surfaces are not high and are reliably protected by the eaves of the roof.

Beams and floor girders are positioned only in the longitudinal direction so that they protrude from the side of the pediment. The beams are fastened with staples and pins, and the resulting lever is also held by the weight of the load from the internal walls.

In narrow houses, the transverse arrangement of the girders is allowed, while the ends of the beams do not protrude beyond the line of the side wall. The front and rear buttresses are formed by extending the interfloor harness to the required distance.

The structure is strengthened if it is necessary to expose the ends of the beams, and they are rarely laid. In this case, corner-shaped supports are used from the bottom of the protruding ends. The protrusions on the sides and gables of the structure are made by extending the ends of the beams on the front and back lines, and strapping elements are placed on the sides.

Short post method

The method provides for the formation of protruding elements in different parts of the building and on any floors, thanks to the perfect structure of the floor between the levels. It is difficult to push the walls of the upper tiers to the sides using the old method of long posts, so the builders switched to a more refined method.

In particular, this applies to buildings at intersections, when the windows of the neighboring sides of the house looked at the intersecting streets. These surfaces were subject to precipitation, and floor ledges were needed to drain water from the structural elements of the frame.

In such buildings, two back walls were without buttresses, and the front ones had steps, although the area of the ledges did not allow making a balcony or bay window on them. The overlap girders moved forward only and at their ends there was a support beam for installing the racks.

A cohesive bar was pulled out from the side and the frame of the upper wall was formed on its surface. Beams did not protrude from the back of the building, as well as from the other side, which did not face the main street.

Features of the structure of half-timbered houses with their own hands

The construction of the frame is a laborious procedure. Before starting construction, a project is required to take into account all the nuances for a particular building. Flaws will lead to a distortion of the house, loss of fillings, sediment in the ground.

Algorithm of actions:

- It is better to make the choice on a monolithic tape-type foundation, while the width of the strip should not be more than 50 cm, since no large loads are envisaged.

- For load-bearing elements, it is better to take glued laminated timber, you can replace it with completely dried dry sawn timber with a section of 150 x 150 mm.

- The lower harness is placed on the foundation along the waterproofing layer, the timber is fastened with anodized anchors, and the wooden elements are connected in a groove-thorn method.

- Connections that are subjected to static or dynamic loading are additionally fixed with metal plates or corners, sometimes through studs are used.

- The depth of the frame frames is increased in the area of the planned installation of blank walls in order to place the insulation layer.

- Internal partitions are arranged from bars of a smaller section, elements of 50 x 40 or 50 x 60 mm are taken, they are attached to the ceiling with anchors, brackets.

- It is better to make insulation with cellulose mats, the size in thickness is determined by the heat engineering calculation.

Longitudinal girders are mounted on transverse bars, and a plank covering is placed on top of them. If necessary, the crossbars are placed above the tie tier between the floors. The frame of the half-timbered house is strengthened with open or closed braces at the corners.

For heating, standard systems or modern methods are used:

- recuperators;

- solar panels;

- fuel pumps;

- warm floors of various types.

Fireplaces are installed as additional heating. They are made of cast iron with a closed combustion chamber and heat-resistant glass. Ventilation is performed in the form of a Canadian well, when pipes are laid in the ground at a depth of 1.5-2.5 m for cooling, and the energy of the subsoil is used.

The roof is designed so that there are wide cornices, they will protect the walls of the house from precipitation and heat.

Fully transparent facades are made using electrochromic glass, the transparency of which is changed by the control panel.