The alignment of the bearing surfaces is a prerequisite for renovations using modern finishing materials. One of these activities is to fill the floor in the apartment with your own hands. This procedure is quite laborious, but technically it is not particularly difficult. Any owner can do it, subject to the sequence and volume of each stage of work.

What is a floor screed

A screed in construction is a layer of solid material poured into a slab in liquid form. Its purpose is to create an even and solid base for laying the finishing cladding - laminate, ceramic tiles, parquet boards. The base should be leveled if the height differences exceed 1%.

According to the method of application to the surface, bulk compositions are divided into the following types:

- Manual alignment. Mixes are prepared from several components and distributed between the beacons using a shovel, rule or spatula.

- Self-leveling. They contain plasticizers that ensure the independent distribution of the solution exactly horizontally. Landmarks are not applied, the correction consists in ridding the liquid of air bubbles.

It is not necessary to pour the solution when linoleum is used as a coating.

Varieties of floor screed

The need to align the base for flooring can arise both in the private sector and in an apartment in a multi-storey building. In each case, on the way of repair, certain restrictions may arise associated with the peculiarities of the structure as a whole and the premises separately.

Depending on the specific circumstances, do-it-yourself floor pouring can be carried out using the following types of mixture:

- Concrete or cement. Concrete is made from crushed stone, cement, water and sand. There are no stones in the grout. Heavy mortar is used in the construction and renovation of one's own homes, where there are no restrictions on the limit of the vertical load on the supporting structures.

- Self-leveling. The mixtures can be used both for leveling and for eliminating large defects that have arisen during the pouring of the supporting structure. Ready-made screeds are lightweight and fast hardening.

- Dry. They are used in cases where it is not possible to weight the building with wet materials or when the wooden floor is leveled on the beams. The composition is made from cement mortar and lightweight fillers from balls and granules.

When choosing a material, you need to take into account its specific gravity, durability and insulating characteristics.

Required screed thickness

For each composition, there are standards regarding the minimum layer thickness with which it can be poured:

- concrete, sand-cement mixture - 30 mm;

- semi-dry composition - 40 mm;

- plaster-based pouring mortar - 50 mm.

It is advisable to increase the thickness of the fill when it is used as an array for placing water heating pipes.

Tools and materials

To fill the floor in an apartment with your own hands from a cement-based mixture, you will need to prepare the following set of tools and materials:

- building level, tape measure, rule;

- paint brush;

- shovel, wide steel spatula;

- a hammer;

- mixer;

- cement, sand, fine gravel;

- plasticizers, primer;

- perforated corner;

- a container for preparing a solution or a concrete mixer.

Pouring floors in an apartment is a technology associated with the formation of a large amount of dust and dirt, working with potentially dangerous tools. It is recommended to use rubber boots and gloves, goggles and a respirator.

Stages of preparation for pouring

The correct approach to the manufacture of a screed involves a number of preparatory measures with a room and a base for pouring.

This is done in stages in the following sequence:

- Removal of furniture and other interior items from the room.

- Dismantling the old coating. Cleaning of the base, its inspection in order to identify defects - cracks, cracks, holes, mold, stains of paint and grease.

- Removing dirt from the surface, sealing all holes with cement mortar or sealant.

- Treatment of the slab first with an antiseptic, and then with a deep penetration primer.

- Determination of the zero level with a mark along the perimeter of the walls.

In conclusion, it is advisable to take measures to protect the bottom of the walls and doors from dirt. To do this, they should be pasted over with foil and masking tape.

DIY floor pouring technology

The work is carried out in the following sequence:

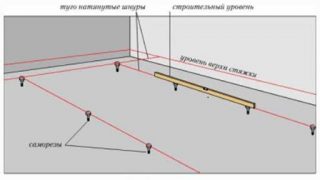

- Installation of beacons. First, holes are made on the floor, dowels are inserted into them, self-tapping screws are screwed in. They are aligned to the zero level. From the cement mortar, along the self-tapping screws, the tracks of a triangular section are laid out 2 mm above their caps. A perforated profile is laid on top of the track and the rule is pressed against the hardware with force. The guides must dry for at least a day.

- Preparation and pouring of the solution. The best option is the proportion of water, cement, sand and fine gravel in a ratio of 1: 1: 3: 3. Mixing is done manually with a shovel in a pallet; for large volumes, it is better to rent a concrete mixer. The solution is poured between the guides, evenly distributed, and then leveled with a rule. This is done until the last section is ready.

- Leveling the surface. This is done after 3-4 hours, when it has hardened enough, but still remains loose. The procedure is performed by a rule, a grinder with a diamond wheel or a rented device - a helicopter.

It will take 10 to 28 days for the screed to completely harden, depending on the temperature and humidity. Then it needs to be treated with impregnation, after which the coating can be used for finishing.