Sports performances on a crossbar apparatus are part of many tournaments. The structure is a steel bar fixed on vertical supports, sometimes it is placed on metal guy wires. You can build a horizontal bar with your own hands in an apartment, in the courtyard of your own or multi-storey building. Pull-ups or upside-down lifts will increase your fitness level.

- Features of the horizontal bar

- Types of projectiles for self-production

- Pros and cons of homemade designs

- Choice of materials

- Calculation of materials

- Tools for the job

- Installation rules

- Crossbar diameter

- Step-by-step manufacturing instructions

- Horizontal bar parallel bars

- In the doorway

- Between two walls

- Ceiling

- To the Swedish wall

- Street option

Features of the horizontal bar

The projectile is suitable for training people of different levels of fitness, body weight, age. The dimensions of professional horizontal bars are governed by the rules of the International Gymnastics Federation.

Standard dimensions:

- the bar is placed at a level of 2.78 m from the level of the supporting surface;

- the length of the crossbar is 2.4 m;

- thickness is not more than 2.8 cm.

In case of individual production, the dimensions are taken taking into account the height of a particular user. In the classroom, a person uses his own body weight, does not use other gravity amplifiers. The projectile is actively used not only to improve the shape, but also during rehabilitation after operations, muscle and bone injuries.

Types of projectiles for self-production

Horizontal bars are placed outdoors and indoors. The functionality is chosen depending on the number of accessories combined with the horizontal bar.

Outdoor options:

- the crossbar is fixed on the trunks of two trees;

- the plank is placed on pillars, concreted into the ground;

- for fastening, vertical fences of existing buildings are used, for example, houses, gazebos, utility rooms.

For installation, choose a flat surface or make a special platform. It should have a soft coating in the form of soil, grass, rubberized layer.

Types of horizontal bars for an apartment:

- Wall-mounted ones are fixed to the unoccupied area of the wall: the supporting structure is bolted to the vertical plane.

- Overdoor structures are placed above the entrance opening. The model is convenient because the wall will not interfere with the legs when pulling up.

- The angular shape is also referred to as wall-mounted, its supporting parts are mounted on two adjacent surfaces.

- Sliding is installed in the door aisle. It is important to select the cross-section of the supporting elements so that they can withstand the load.

- Hinged and removable products are supported on opposite walls located close to one another, for example, in a corridor up to 1.5 m. For this, grooves are formed in the surfaces or overhead holders are placed.

There are options for adding to the Swedish wall, if there is one already in the room. Ceiling models are fixed to the upper floor slab, beam.

On a single bar, you can only pull yourself up or do coups. Modify the structure to weed out exercises of varying degrees of complexity and appearance.

The crossbar between two supports, for example, thick trees, walls in the room are complemented with handles of a peculiar shape, which make it possible to grasp the bar with different grip.

There is usually a lot of space in the yard, therefore they combine the Swedish wall, gymnastic staircase.

Pros and cons of homemade designs

If you assemble the horizontal bar on the wall with your own hands, it becomes possible to correctly complete all the devices of your own free will.

The advantages of a homemade design:

- the ability to make a product for the dimensions of the room, choose the perfect place in the yard;

- the likelihood of adjusting the parameters to your own body weight, and adding equipment for children's activities.

The disadvantages are the time spent on the design of the structure, selection of materials, cutting, assembly and installation. It is difficult to work with welding in an apartment if there is no garage nearby.

Choice of materials

For a sports equipment, the main quality is reliability, so the materials are chosen with this requirement in mind.

Steel pipes are used:

- For internal use, black iron pipes are taken, and after welding, the walls are cleaned with a grinder, primed, painted with metal compositions.

- For outdoor installation, they take the same materials, but the processing is made more difficult - they include an additional layer of an anti-corrosion compound against rust.

Steel elements in the construction of a homemade horizontal bar serve for a long time, easy to maintain and handle. For painting, epoxy compounds, nitro paints, alkyd and oil enamels are used. Powder coating works well, but it requires special equipment.

Wood is cheaper, easier to process, and no welding machine is needed for assembly. The disadvantage of wood is that after some time of operation, the material loses its bearing capacity and collapses. The crossbar and pillars protect against the effects of climate and microorganisms.

Calculation of materials

General list of materials without reference to dimensions:

- round pipe for the manufacture of the upper bar with a diameter of 20 to 30 mm;

- a rectangular profile with a diameter of 30 x 40 mm for a frame, it is cut into the number of segments indicated in the drawing;

- anchor for fixing in the walls;

- metal plate made of iron with a thickness of 4 - 5 mm;

- wooden blocks for decorating the landing nest, if the crossbar is placed in opposing walls.

The bars are changed with thick plywood (18 - 22 mm), a metal blank with a sample along the diameter of the strip. Fixed models are fixed by inserting into pipe cuttings.

Tools for the job

A measuring and verification tool is prepared: a tape measure, a laser or bubble level, a carpenter's square for exposing parts at 90 °, a construction marker. Metal parts are joined using a welding machine.

Other tools will be needed:

- a tool for working on metal (cutting and grinding), a grinder with a suitable circle, a hacksaw with fine teeth;

- file, hammer, pliers, wire cutters;

- drill with attachments for screws and bolts, wrenches, screwdriver.

Brushes are used for priming, the paint is diluted in special cuvettes with a shelf for wringing.

Installation rules

Place the projectile taking into account the requirements:

- solar lighting - the horizontal bar should not be in a lighted place from morning to evening, since physical activity is dangerous in such conditions;

- dampness of the soil - evaporating moisture makes breathing difficult, and in winter, when freezing, the heaving force can push out the lungs;

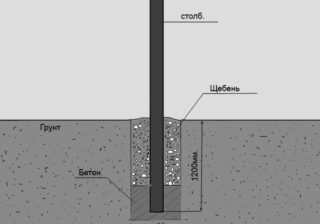

- the pillars must be concreted, the lower parts are wrapped with roofing material in two layers or coated with molten resin three times.

You need to make a crossbar for a street horizontal bar at such a height that you can reach it with the fingers of an outstretched hand, standing on your toes. In the room, the distance from the plank to the ceiling is made at least 32 cm.

Crossbar diameter

The size of the pipe section is important, attention is also paid to the selection of the wall thickness. Standard recommendations are intended for people of average height, with an ordinary palm size.

Diameter selection rules:

- measure the palm at the beginning of the fingers;

- the result is multiplied by 3.3;

- the value is rounded up to zero or five.

For example, the width was 9 cm. After multiplication, 29.7 cm are obtained. The diameter of the strip is taken from 30 - 32 cm. For the crossbar, it is better to take a round product, and profile rolled products are used for the frame, racks, and other fasteners.

Step-by-step manufacturing instructions

Be sure to choose racks of the correct section or fix the horizontal bar to reliable walls, thick trunks. A preliminary drawing is made of a wall horizontal bar with devices 3 in 1 or 2 in 1. For a single floor or over-door crossbar, a diagram of the assembly and installation of elements is also being developed.

Step-by-step process:

- nests are welded onto walls or racks to fix the ends of the crossbar;

- if the plates are made of wood, they are cut into the door frame or attached to the walls with anchors at the required height;

- try on and cut the bar to size.

The crossbar is placed in the prepared nests. The accuracy of installation is checked with a level, if racks are used, a plumb line is used. In outdoor conditions, a small canopy or visor is additionally mounted over the training site.

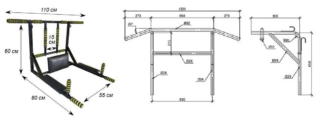

Horizontal bar parallel bars

The bars are made for a narrow and wide grip; such devices, together with a pull-up bar, will cost less than a store model.

The projectile consists of two pairs of vertical tubes. The distance between the pairs is 1.5 m, and between the opposite elements - 0.7 - 0.9 m. They are concreted in pits with a depth of at least 50 cm. Rigid crossbeams from a round pipe are welded to two posts.

The horizontal bar is fixed on one of the pairs of pipes. It is made of the appropriate height. For children, the principle of making a shell is similar, taking into account the height of the child, the size of his palms.

In the doorway

Such a crossbar is made single, it is not combined with the uneven bars, a gymnastic wall. Compact designs are made so that they do not interfere with the movement of people between rooms.

Door horizontal bar models:

- stationary;

- removable;

- folding.

The first type provides for a fixed fixation of the carrier beam. For its installation, round metal pipes are used, where the ends are inserted. For removable, parts are mounted with a sample in the upper part in order to remove the bar if necessary. Folding ones have a complex structure. When folded, the structures practically do not protrude above the opening or inside it.

Between two walls

Such structures are most often placed in the corridor, where the width of the room allows. A folding structure of bars is sometimes placed on the side, a wall for gymnastics is mounted. A detachable model of a children's swing can be played on the horizontal bar.

The pull-up tool in the corridor area does not take up much space, and activities will not interfere with other family members. Fix the ends on the walls in a deaf or removable way. Use pipe mounts or overhead sockets made of iron, plywood, wood. For installation, take dowels or metal anchors with a length of at least 100 - 150 mm. The overlays are decorated to match the color of the walls or leave a contrasting color scheme.

Ceiling

The design is chosen if the room has high ceilings so that the bar turns out to be at the height required by the standards.

Standard details:

- A round pipe for the manufacture of a crossbeam, its length is usually 1.0 - 1.2 m. The ends of the strip at a distance of 20 cm from the edge can be bent at an angle to the floor of the room.

- Two short pipes (15 cm) for a different grip are welded perpendicular to the bar. The distance between them is 20 - 25 cm.

- Ceiling fixing elements such as plates.

- Square profile for uprights.

For people of heavy weight, two more plates are placed on the ceiling, they are placed in the shape of a rectangle. Details of such a horizontal bar are welded together.

To the Swedish wall

This method is used if there is already a wall in the room, and its height allows you to arrange the horizontal bar at the proper level. Take into account the gap to the ceiling.

The fastening plates are bent in the shape of the wall rods, they are taken with an initial length of about 60 cm. The bent part completely encloses the crossbar of the wall, a margin of several centimeters in coverage is allowed.

If the ceiling height in the apartment is 2.5 - 2.55 m, some exercises on the horizontal bar will not work. The crossbar on the Swedish wall is combined with a basketball ring, a climbing rope, and a punching bag.

Street option

They use metal, wooden supports, and erect concrete pillars. At the ends of the underground part of the iron and wooden racks, transverse or cross elements are welded or drilled. They are concreted together with the posts to give additional stability to the posts against pulling out. Installation will be more difficult, but the racks will stand securely for a long time.

Outside, struts are used in the form of guy ropes, rigid inclined elements, the frame in the corners is fixed with diagonal braces. When assembling for bolts, holes are drilled 0.5 mm wider than hardware. The ends of the bolts, after screwing in the nuts, are cut off, grinded with a grinder.