Linoleum is one of the easiest to install and affordable decorative materials. It is capable of imitating different textures, with or without an insulating layer. Self-laying linoleum requires adherence to technology and the nuances of the work.

Varieties of linoleum and styling methods

Before laying the finishing material, you need to understand its varieties and characteristics. By the type of base, the following types of linoleum are distinguished:

- No base. Such a product is homogeneous in structure and is characterized by a high degree of abrasion resistance. The material does not lose color and texture for a long time. It is often installed in rooms where the floor is exposed to intense stress: in office rooms, public buildings.

- Foam-based. This material has a multilayer structure, its thickness ranges from 2-3.5 mm. The decorative layer is applied to fiberglass with chemical or mechanical foam. A protective film is attached on top of it. Such linoleum is intended for rooms that are exposed to high humidity.

- On a fabric insulation. The base is made of felt or jute, over which a protective polymer layer is applied. The material can be glued in household premises with normal humidity levels. In the process of use, there is a slight expansion of the coverage.

There is glossy and matte linoleum. The first type looks expensive, but requires a careful approach to calculating the load. If it is too intense, the product will quickly lose its luster. The matte material is versatile. Caring for it is simple, it retains its decorative effect longer. If you need to protect the floor from slipping, it is better to choose a rough finish.

The material is classified according to the scope of application:

- domestic;

- semi-commercial;

- commercial.

The most durable and durable commercial linoleum is considered.

Use dry or glue method of flooring. The choice depends on the type of product, as well as the area of the room, operating conditions.

Floor preparation for linoleum

The concrete surface is cleaned of dust and exfoliated areas, leveled. If there was carpet in the room, it is removed completely. Tiles should not be removed. It is poured with a thin layer of self-leveling mixture. You can put the coating on the old linoleum, if the latter has no mechanical damage, is not affected by mold, fungus. If necessary, dry the base thoroughly.

Floor preparation instructions:

- dismantling of finishing materials;

- cleaning the base;

- sealing mechanical damage or cracks;

- leveling the surface with a mortar or grinder;

- priming;

- thin screed;

- reapplication of the primer;

- leveling with slab products.

At the stage of preparation, the amount of material is counted.

Laying linoleum on a concrete floor involves the use of a substrate.

Styling features

Before you start laying the material, you need to consider the features of working with different types of bases.

On a wooden floor

Preparation includes filling gaps and joints between boards with putty or using board materials for leveling. The first option will take more time and has some difficulties in application. It is best used when the subfloor is new or there is no risk of deformation.

When using chipboard or fiberboard, a homogeneous and even base can be achieved in a short time. It is not recommended to lay waterproofing on such a floor - the tree must “breathe”. When installing panel materials, you need to leave a deformation gap around the perimeter of the room. A distance of 1 mm is also left between the sheets.

On a concrete base

The base is cleaned of dust and leveled. The difference in height does not exceed 2 mm per linear meter. Protrusions and potholes are removed. If there are too many of them, the screed is made with cement mortar or self-leveling mixture.

You cannot fix linoleum on bare concrete if it does not have a lining heat-insulating layer. In this case, a jute, flax, cork or combined backing is used. It is an additional sound insulator. Another way to prepare a concrete sub-floor is to install plywood or chipboard sheets.

An obligatory stage in the formation of a concrete base is waterproofing. For work, use a plastic wrap. Its thickness is 200 microns. The material should be laid with an overlap of 15-20 cm. The film should overlap the walls. After installing linoleum, excess waterproofing is removed.

Calculation of the required amount of material

Before you put linoleum on the floor, you need to calculate its amount. To do this, determine the area of the room. The technical characteristics and dimensions of the finishing material are indicated on the packaging. The width of the canvas is 250, 340 and 400 cm. It is better to cover the floor in the room with a single piece of linoleum. The need to dock the elements disappears. The flooring becomes more durable and decorative.

The necessary parameter for the calculation is the distance between long walls, while taking into account all the features: recesses for radiators, protrusions. The material is bought with a margin. If it is not possible to choose a single piece of the product, the width of the fragments should be such that the seam between them runs in the center of the room.

Linoleum laying technology

- After purchase, the material is left for several hours in the room in which the repair is being carried out, so that it gets used to the conditions and straightens up. At this time, the product may change slightly in size. You should not accelerate the process of leveling linoleum, as it deforms during operation.

- The room must be kept at the correct moisture and temperature levels. The first parameter does not exceed 4%. If it is larger, the coating will peel off from the base. The air temperature is within 5-20 degrees.

- Fastening of the finish is carried out after the completion of other repair work. It is necessary to make holes in the walls and insert wooden plugs into them so that there are no problems with fixing the skirting boards.

The linoleum laying technology provides for the following stages:

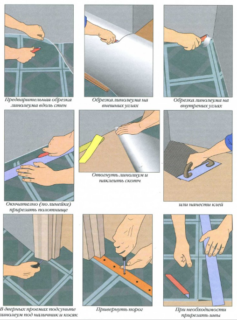

- Cut out the material. You can cut the blade with a stationery knife with replaceable blades or large scissors.During cutting, the symmetry of the pattern is observed, if necessary. It is not necessary to immediately cut the canvas for the finishing version. You can leave the dimensions with a margin of 2 cm, and then eliminate the excess.

- Fixation of linoleum. If a single piece is used, it is pressed against the baseboards. When laying several pieces of material, they can be secured with double-sided tape. The use of glue involves applying it to the entire area of the material in sections.

- Cold welding of joints.

- Installation of skirting boards. They are only screwed to the walls. It is better to use plastic elements, since minor irregularities do not affect the tightness of their fit. The grooves are fixed along the edge of the canvas.

Violation of the installation technology will lead to deformation of the floor covering and the need to re-install.