A covering for a wooden floor is chosen taking into account its good resistance to moisture, cold, since the base gets wet and cooled. Laying linoleum on a wooden floor is the best decorative finish option. Roll material of artificial origin is characterized by low thermal conductivity, does not rot at high humidity.

Features and positive qualities of linoleum

The coating is sold in rolls with a width of 0.5 - 5 meters, the length of the factory strips is 6 - 40 meters. The material has a thickness of 1.5 - 5 mm; by special order, varieties with parameters up to 9 mm are made. You can fix linoleum without glue or connect to the base using polymer-based mastics. There are options with a heat-shielding and sound-insulating layer, which are used in special operating conditions.

The marking contains numbers and letters:

- The numbers indicate the class of use. The first of them speaks about the conditions of use (2 - housing, 3 - public premises, 4 - production). The second figure indicates the permitted type of load (1 - small, 2 - medium, 3 and 4 - high and very high).

- The letter indicates the degree of wear. F and M - low degree, P - medium, T - high.

The positive qualities include the durability and stability of the coating, the manufacturer determines the service life of 10 - 15 years. Linoleum tolerates UVF radiation, is easy to clean and has an acceptable cost.

Varieties of linoleum

Household options are made on a polyester basis; such materials are distinguished by a complex structure. Linoleum lasts up to 8 years with a high degree of workload, it is produced in different colors and patterns. Commercial varieties can be laid in high traffic areas and have good wear resistance, but there are few design choices.

According to the raw materials, linoleum is divided into the following types:

- natural material;

- PVC coating;

- relin (rubber binder);

- colloxycolic (nitrocellulose);

- alkyd.

By structure, linoleum is divided into homogeneous and heterogeneous. The first type is a homogeneous web of PVC granules and dyes, which are evenly distributed throughout the mass. Heterogeneous PVC material consists of several layers (up to six), the main raw material is fiberglass. Linoleum has a backing made of foamed polyvinyl chloride, non-woven fabric, natural fabric.

Natural

Such linoleum is produced without a base or a substrate of hemp, jute, linen threads is placed, the composition includes the resin of coniferous trees, linseed oil, wood flour, lime powder and natural dyes.

Installation is carried out on a wooden floor, subject to high-quality insulation from moisture and good insulation. The material on a natural basis is environmentally friendly, does not emit harmful components even when heated to high temperatures. Resistant to heat, therefore it is recommended to install it as a covering after installing the underfloor heating system.

The qualities of natural products in warm and dry rooms:

- high resistance to wear and tear;

- weak flammability;

- antistatic properties;

- inertness to fat, non-concentrated acids and alkalis.

The disadvantages include the high price. In the cold, the material becomes hard, fragility increases. In a damp room, natural material does not last long and decomposes, since microorganisms and mold act on it.

Pvc

This variety wins in cost, while the coatings do not conduct heat well and are good protection against cold. The canvas contains artificial components, but when choosing the right operating conditions, the material remains completely harmless.

Qualities of PVC linoleum:

- shows dielectric properties;

- has limited solubility in alkalis, acids;

- does not rot in wet conditions;

- simple installation technology.

The products are produced on a foam PVC backing with a sponge-like consistency. On the PVC market, the variety is represented by a variety of collections with many options for patterns, colors and textures.

At high temperatures, PVC products release harmful components into the environment. This type cannot be laid on warm floors in an apartment, since the material collapses when heated. In the cold, the coating cannot be laid, since it cracks and breaks.

Alkyd

Another name for this traditional material is glyphthalic. Alkyd resins, mastics, dyes are used for the manufacture. Woven and non-woven fabric serves as a substrate. The composition contains natural ingredients (up to 23%) in the form of cottonseed, soybean, linseed oil, sunflower, tung and hemp oils are also used. To reduce the cost of the material, bottoms are used when producing fatty artificial acids.

Characteristics of the alkyd variety:

- low abrasion rates and long service life;

- small deformation under the action of mechanical pressure;

- water absorption does not exceed 6-10% of the mass of linoleum.

Alkyd material can be laid in public and residential buildings, it is used in children's and medical institutions, installed in production workshops and large sales areas. Glyphthal linoleum lasts a long time if it is not exposed to alkalis, solvents and acids. To fix the coating, cold coumarone-rubber, bituminous mastics are used.

Colloxylin

Another name for this type is nitrocellulose, which indicates the presence of an artificial polymer in the composition, they also include compounds of red lead, gypsum, colloxylin, plasticizers, petroleum jelly, and alumina are used. This type of linoleum is produced without a backing. They produce a monochromatic version of brown or reddish color scheme, with a multi-colored surface, but the choice of shades is not large.

Distinctive qualities of colloxylin material:

- elasticity, bending strength;

- water resistance;

- environmental Safety;

- long service life;

- beautiful appearance.

The disadvantage of nitrocellulose linoleum is its high degree of combustion. Due to the increased fire hazard, the material should not be laid in kindergartens, schools, hospitals and other public places.

Relin

Produced from natural and synthetic rubbers, the material is a rubber floor covering with a thickness of 3 - 6 mm. Previously, a two-layer version was produced, in which the upper part was made of multi-colored rubber, and the lower part was made of rubber chips. Nowadays, secondary raw materials are not used.

Relin properties:

- high strength, resistance to wear, abrasion;

- flexibility, elasticity;

- poor conductivity of heat and sound;

- moisture resistance and resistance to the action of cleaning agents.

For aggressive industrial environments, a rubber coating is produced with the addition of elastomers in the form of ethylene-propylene rubber.There is a material with increased antistatic characteristics. They produce grooved surfaces to reduce the risk of slipping shoes and falling people. Relin works without loss of quality at a temperature of -40 ° C - + 70 ° C.

Tools and additional materials

Adhesive mastic is purchased so that the floor carpet bonds securely to the substrate. The composition is selected after determining the type of linoleum and the substrate material.

Other materials will be needed:

- double sided tape;

- docking rail;

- putty for smoothing uneven areas;

- back strap;

- cold welding;

- screws, nails when laying on a plank floor or a plywood or chipboard base.

The instruction recommends cutting the linoleum cloth with a special hard knife.

You will also need:

- marking long strip-rule (2 - 3 m);

- spatula for applying glue mastic;

- roller-roller for smoothing linoleum;

- a hammer.

The markings are carried out with a tape measure, the marks are made with a felt-tip pen, a thin marker.

Preparing the wood floor

Linoleum carpet requires a flat area, otherwise the unevenness will appear after a while. It is recommended to lay chipboard panels on a plank floor, since the boards sag when walking and tear the linoleum, especially if a thin coating option is chosen.

Preparation:

- the old paint is removed from the boards by heating the layer with a construction hairdryer, then a spatula is used;

- the plank covering is scrolled with self-tapping screws along load-bearing logs or beams, depending on the design;

- the surface is planed with a hand plane or using an electric grinding technique for parquet;

- clean the area from dirt, dust, primer or lay chipboard panels, moisture-resistant plywood.

Irregularities on a wooden surface can be filled with special woodworking compounds. The surface is preliminarily cleaned with a vacuum cleaner and a special primer is applied. DP sheets are glued on parquet glue or PVA is taken, then fastened with hardware to the floor. The panels are placed with an offset of the joints, the cracks are putty with mastic, polished.

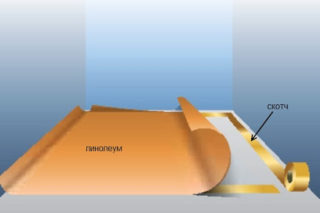

DIY linoleum laying instructions

Installation instructions:

- dismantle the skirting boards in order to properly cut the strips of linoleum;

- cut with a knife, while leaving small tolerances for the shrinkage of linoleum, displacements will manifest themselves when the air in the room is heated;

- the protrusions are cut out after the carpet is laid out in the installation position and the contour is drawn on the linoleum covering.

The error cannot be corrected, therefore all measurements are taken carefully.

If the stripes are not wide, and the room is large, the seams are placed perpendicular to the window opening.

How to lay on uneven wood floors

The bumpy base must be leveled; for this, the putty method is used or self-leveling compounds are poured onto the surface. Use dry mixes that are designed for woodworking. Modifiers and synthetic fibers are added to them to create a durable layer.

Before using the mixture, thoroughly waterproof the surface so that there is no water leakage. Use sealant or foam. The area of the plank base is dried and primed. A reinforcing mesh is placed on the surface and the solution is poured. Align the composition with a spiked roller, wait for solidification, then lay the coating.

The mastic is applied immediately to the entire surface or applied in separate areas under each area. Untreated strips 10-15 cm wide are left up to the wall for subsequent shrinkage.