The process of building a wooden house consists of several stages: the construction of the foundation, walls, roof arrangement. In addition, you need to take care of the interior decoration. The subfloor is laid in a certain sequence, depending on the materials used. You can do this yourself, strictly observing the installation technology.

Requirements for the floor of a wooden house

Regardless of the construction material of the building, the floor must meet the following requirements:

- The elements of the base must be strong enough not to sag under the weight of a person, not to squeak.

- It is impossible that on the basis there are any flaws or damage, deflections.

- The structure should keep the warmth inside the room to the maximum.

- If wooden elements are used for laying the sub and final floor, they must be treated with antiseptics and fire retardants that protect the material from inflammation, the development of fungus and mold, and the appearance of insects.

- It is necessary that the structure has good decorative properties, as well as characterized by a long period of operation.

To lay the floor in a wooden house, you need to know the technical characteristics of the selected material, how to fix it, and the conditions of use.

Varieties of floor materials

In a wooden house, for facing surfaces, you can use a board, parquet, ceramic tiles, laminate, linoleum. Each material has its own characteristics that you need to know in order to make the right choice.

Board

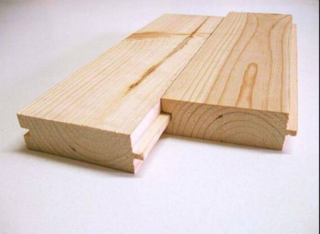

Solid wood is used for the manufacture of floorboards. The length of the element varies from 0.9 to 6 m, the thickness is 1.8 to 6 cm. Each wooden panel is equipped with a tongue and groove. To connect the boards to each other, you need to insert a spike into the groove and tap it easily with a rubber mallet or mallet.

Oak and larch are used for the manufacture of finishing materials. Conifers are characterized by rapid wear, therefore they are rarely used.

The advantage of the material is a low level of thermal conductivity, good strength, ease of installation and repair. However, its cost is high. Such a floor requires additional processing with protective impregnations, varnish.

Glued timber is characterized by high strength and low risk of deformation, but its cost is much higher. The material can even be used on open terraces and attic floors.

Ceramics

Tiles are a great option for a bathroom, kitchen. It repels water well, does not collapse under its influence, protects the base. The tiles are easy to maintain, as they can be cleaned with chemicals and abrasives. The coating is characterized by high strength and resistance to sudden temperature changes.

Parquet

Floor parquet is traditional for a wooden house. It consists of strips made of wood, which, during production, acquire the required shape and are polished. Material is made from solid wood: oak, birch, bamboo.Despite its strength, parquet does not interact well with humid air; it can warp under the influence of temperature extremes. Every 5 years the surface of the floor has to be scraped and varnished. You can lay the parquet with your own hands, but this process is quite complicated and requires certain skills.

Laminate

This finish is made from compressed waste wood lamellas. They are based on a fibreboard on which a drawing is applied. At the final stage of manufacturing, the products can be laminated. The thicker the protective layer, the longer the coating will last. Choosing a cheap option is not worth it, since it has a short service life.

The laminate is installed quickly, as it is equipped with a special locking system. Subject to the installation technology, the joints remain strong for a long time. Another advantage of laminate flooring is the ability to imitate natural wood.

Linoleum

Linoleum contains synthetic components, so it is rarely used in a wooden house. Its advantage is a variety of colors and textures, ease of installation, ease of maintenance, affordable cost, high resistance to the influence of negative factors.

Rough and finish floor

The subfloor must provide a level surface for the installation of the finishing finish and properly distribute the load on the floor covering. Such a floor can be made in three ways: using wooden logs, plywood, concrete pouring.

Wooden on logs

Wooden elements must be fixed to a foundation or plinth. You need to step back 2 cm from the walls to create a deformation gap. Lay the base after mounting the strapping from the bottom. Long boards of small thickness are used for its manufacture. Lags are attached to it with metal anchors. They should not be too rigidly fixed. The distance between the joists is 40-60 cm. The choice depends on the insulator used, as well as the load that the floor covering will experience. The cross-section of the timber ranges from 15 * 10 cm to 15 * 20 cm.

Pouring with concrete

A concrete sub-floor in a wooden house is used less often. He needs mandatory insulation. The advantage of such a base is strength, reliability, durability. Thanks to the self-leveling mixture, an ideal horizontal level of the surface can be ensured.

It is possible to lay the concrete mixture directly on the ground or along the logs. Preliminarily, beacons are installed in the room, between which the solution is poured. Rules are used for alignment.

After pouring the concrete, the rough layer is covered with a film and left for several weeks so that the water does not evaporate from the mixture too quickly. Otherwise, the base will crack.

Plywood flooring

Plywood is used as the base for the flooring. It can be laid on logs or cement screed. In the first case, the bars must be positioned so that the joints of the sheets fall on them. During the installation of the structure, you need to monitor its horizontal level. Insulation is laid between the lags. Sometimes plywood is laid in two layers. In this case, the seams in the first should not coincide with the joints in the second. If the plywood is mounted on a cement base, waterproofing is required.

Materials for processing lag

High humidity, temperature drops have a negative effect on lags. To avoid problems with the roughing coating, it must be treated with special protective compounds. There are several types of such funds:

- Bioprotective antiseptic. The preparation protects wood from rotting, the appearance of blue spots, the development of mold and mildew, and insect damage. The product does not lose its properties for 25-30 years. Usually, the antiseptic is sold in a concentrated form.Some quality control formulations contain pigment. The preparations are environmentally friendly, after application they emit a faint odor, which disappears over time. They do not cause allergies.

- Indelible antiseptic. The option is great for rooms with high levels of humidity. The advantage of the tool is its low consumption.

- Folk methods. To improve the technical characteristics and increase the service life of wood, you can treat wood with transformer oil, resin, engine oil.

The choice of protective agent depends on the conditions of use of the wooden floor.

If boards are laid on top of the base, they can be painted or varnished. The cladding material is laid 5 cm above the base. If in the future the finishing layer needs to be changed, it is better to use self-tapping screws for fastening.

Do-it-yourself floor installation in a wooden house

Most often, the finishing material is mounted on a wooden base based on a lag. The beam is laid on a concrete slab, directly on the ground, on props or on ledges along the walls.

Floor Installation Instructions:

- Selection of tools. For work, you will need a grinder, a saw, a drill or perforator, a measuring tape and a building level, a chisel, a nail puller, a screwdriver, a paint brush. If a concrete base is chosen for laying the finished floor, a concrete mixer, shovels, a trowel, and pliers are required for its manufacture. The specified layer requires reinforcement with steel mesh.

- Installation of lag. They are laid so that the beams form an even and solid base. During the installation of the elements, their horizontal level is constantly monitored. For laying all the elements, cords are used stretched between two landmarks. After lag alignment, they are fixed.

- Laying a waterproofing layer and insulation. To protect the structure from the influence of moisture, a plastic wrap is laid on it, and the material should go onto the walls. The canvases are laid with an overlap, and their joints are fixed with masking tape. Between the logs, mineral wool mats are mounted or expanded clay is poured.

- Rough layer masonry. Untreated boards are used. They must be dry and protected from moisture and temperature extremes. The length of the boards should be such that their edges fall on the timber.

- Ventilation arrangement. The air can be made in boards at a distance of 3 m from each other. They must be covered with a steel grate. The first element of the subfloor is laid at a distance of 2 cm from the wall. It is necessary to fasten the elements with self-tapping screws or nails. The ends of the boards are arranged with bandaging of the seams.

- Finishing finish. Laying decorative material involves grinding the rough surface, sealing existing cracks, applying a primer. If laminate or parquet flooring will not be used, the boards can simply be treated with paint or varnish. To do this, use a brush or roller.

To correctly make a decorative floor in a private house on logs, certain skills and adherence to instructions are required. A high-quality coating will last for more than one year, and will not need frequent repairs.