The balustrade is a low railing of a staircase, a terrace, including a line of sculptural posts. Balusters from above are connected by a horizontal beam, curly elements are made of metal, wood, PVC, concrete. The installation of handrails on the stairs in the form of a picturesque balustrade transforms the perception of the transition zone between the two levels and performs the usual protective functions against falling.

Requirements for stair railings

Building codes regulate the height of the railing so that it reaches at least the waist of the person.

Fences must be in height:

- not less than 0.9 m on internal spans;

- from 1.2 m in preschool institutions and on evacuation stairs.

The handrails prevent people from falling from a height beyond the line of the square, they are supported by the hand when walking, descending and ascending. The fixing of the handrail to the staircase must be strong and ready to support the weight of the person. The surface of the support elements is made smooth so as not to injure your hands.

The dimensions of the handrails, with or without balusters, are tied to the size of the person and his functionality when moving between floors. The dimensions do not change depending on the increase in the horizontal and vertical parameters of the building.

Design features of balusters

Balusters are made in the form of figured pillars, columns, carved and stucco decor on the surface. Racks are basic (support) and intermediate, depending on the installation site.

Structural elements:

- ordinary balusters;

- support pedestals;

- lower beam;

- railings.

Supports are placed at the beginning and end of the span, at turns. Long passages are provided with additional root elements. They are made from different materials, the properties of balusters depend on this:

- Wood. Used in interior design. Outside, the tree is moistened and cracked in frost. The material is environmentally friendly, but requires regular maintenance.

- Metal. Use elements made of stainless steel or wrought iron. In the open air, you can do the fastening of the posts and balusters of the stairs after the anti-corrosion coating. A wide variety of shapes makes steel railings attractive

- Plastic. Injection molded PVC parts do not rot or deteriorate from weathering. They are used in housing and social construction.

They make gypsum, concrete cast structures of various shapes. Gypsums absorb water and require special treatment. The concrete is durable and does not deteriorate, but decorative processing is needed due to its unattractive appearance.

Calculation and manufacture of parts

0.6 cm is measured from the side contour of the upper step and the same gap is set aside from the border of the lower tread, the marks are set using a square in order to have minimal deviations and an even line of columns.

The next step is to find the installation step. The parameter depends on the number of columns and their diameter. Usually they take a distance of 12 - 15 cm with a column thickness of 4 - 8 cm. In a house with children, the installation of handrails on the stairs is done in steps of up to 8 - 10 cm for safety reasons.

For manufacturing, templates are prepared, taking into account:

- sectional shape;

- number of faces;

- preparation method;

- material;

- type of attachment to the stairs.

Wooden balusters are made on a machine, metal ones are grinded or forged and welded, monolithic ones are poured using molds.

Fastening pillars

It is not enough just to fix the balusters and railings made of wood to the floor, since after such fixation the pillars will sway under load. For the final installation, a connection with a railing is used, which is made in the form of an upper beam of various shapes and sections. For intermediate elements, sometimes only fastening to the steps is sufficient, if they are monolithic and massive.

First, a support element is placed at the top of the march, then a similar lower part is mounted. They are marked and fixed so that there is a small gap (about 5 - 7 mm) between the body of the figured column and the vertical part of the adjacent step. The distance will prevent the baluster from rubbing against the riser, and the characteristic squeak will not be heard.

Methods for installing balusters

The root elements are under heavy loads, so you need to fix the balusters to the steps and railings of a wooden staircase, regardless of the method of fixing ordinary posts. Reinforcing pedestals in the form of a broadened base are sometimes placed under them.

Mounting methods are used:

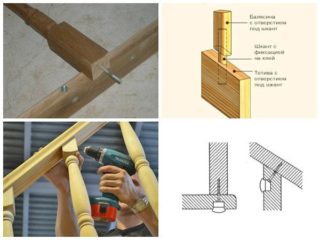

- dowels made of wood or dowels;

- iron studs, bushings, pins;

- self-tapping screws with anodized coating.

Wooden fasteners dry out over time, a network of cracks appears on it. The destruction leads to the gradual loosening of the railing. The iron mount is strong, but wood is crushed around it, so the joint is loosened during operation. There are adjustable threaded studs to tighten fasteners and restore stability.

Stiletto heels

Use through studs, which are conventional or combined plumbing. The second version is made in the form of a screw-screw, while the lower section is equipped with a thread for a nut, and the upper part is made like a self-tapping lance.

Installation begins with drilling a through hole in the step, the bottom of which is bored to fit the nut and washer. The hairpin is inserted from below and the retainer is put on the thread. The baluster is screwed on top of the installed fasteners. Previously, a hole is made in the center of the column with a diameter slightly smaller than the size of the self-tapping screw in order to assemble the structure without cracks.

The nuts are tightened over time, as the tree is crushed. Loosening is prevented by spreading glue on the tip of the stud.

On dowels

The element is a round wooden pin with a diameter of 3 - 15 mm. To strengthen the docking, longitudinal notches are made on it. It differs from a hairpin in the way it is fastened in a step. It is not based on a thread, but is held in place by friction.

For installation, a blind hole is made along the diameter of the dowel in the center of the baluster and in a designated place on the step. The diameter is chosen slightly less than the size of the dowel, so that during installation it needs to be hammered. Before driving, glue is placed in the hole, and the lining is knocked with a hammer, which is placed on the dowel.

In ladders on a bowstring, the balusters are attached to the sub-baluster panel. At first, the columns are fixed to the under-balusters from below through it. The decorative elements are simultaneously attached to the string after installing all the details.

On self-tapping screws

Fixing on self-tapping screws is rarely used in the form of an independent method of mounting balusters. The caps of hardware sometimes break off, so this is not suitable for attaching intermediate and supporting balusters. The method is used to temporarily fix the elements in the design position and to additionally attach the parts.

Self-tapping screws for wood with coarse threads are used in a position at an angle, and the hardware is screwed in until it stops (until the cap is completely buried). The resulting holes in the racks are sealed with a putty for woodworking. Self-tapping screws are chosen with a galvanized coating so that they are less susceptible to corrosion. The length of the hardware differs in each case, but more often the size of 45 - 80 mm is used.

Fastening handrails

They use the installation method using a sub-rail - boards, where the balusters are fixed through and through. A railing is placed on top of the girder, in which a groove is cut out from below along the dimensions of the longitudinal element. You can install balusters and railings on a wooden staircase without an additional board, for example, put on glue, while additionally fixing it with self-tapping screws from below.

Installing handrails:

- pins or dowels are placed in the center of the exposed columns;

- the railing is applied from above and tapped through the gasket to print the marks;

- holes are drilled in the designated places for the counterpart of the dowel.

The docking is checked, then the handrail is removed, the holes are coated with glue and finally set, tapping with a hammer through a wooden gasket.

Final processing of the railing

The wooden elements on the railings are sanded with electric tools. A grinder is used with special circles with emery. In the process, the protruding corners are rounded, the surfaces of the flat parts are leveled. The resulting dust is mixed with wood glue and clog the holes for embedding fasteners with it.

The railings are made of expensive woods and varnished to show the beauty of the pattern. Use a light color stain to show the positioning by dragging, and then use several coats of varnish. They paint the balustrade if the details have visual flaws, are worn out, or the interior needs a certain color of the railings.