The device for automatically closing the door leaf extends the operating time of the hinges and eliminates the need to cover the door leaf manually. Installation of a door closer is provided in aisles with visitor control, on emergency and fire exits, as well as on entrance doors with a large flow of people. The mechanism reliably closes the door if used according to the instructions. Unauthorized activities will damage the device.

Types of closers

The choice of a closer depends on the operating conditions. They produce thermostable models that operate in a wide temperature range. In the heat, the oil inside the device flows at an accelerated rate, while the damper compensates for the decrease in the viscosity of the substance; in the cold, the situation changes.

By the structure of the mechanism, closers are:

- spring type - refer to outdated models that do not depend on the magnitude of the moment when opening;

- with a toothed bar and gears - are a common type based on a hydromechanical contour and a rack and pinion transmission;

- cam mechanisms based on a profiled eccentric between the spindle and the elastic part - they set different moments in magnitude.

The correct adjustment of the mechanism plays a role so that users do not have a desire to help close the door leaf. Covering force is standardized and subdivided into classes EN1 - EN7, while the category does not depend on the weight of the canvas, but on the inertial moment and the size of the shoulder. Inexpensive options often have the EN4 class, they have a scheme for adjusting the closing force within the normal range.

Overhead

The devices must be installed over the door leaf, and the counter fittings must be placed on the box or in the area above the opening. The design is one of the practical options with simple installation.

Installation of an overhead door closer is carried out in trade pavilions, offices, where you need to gently close the canvas and hold it in this position. Powerful mechanisms work with iron doors, natural wood doors, thick glass.

There are two constructional methods for transferring the load to the spring.

- The gear drive acts on a pinion, which drives a pin or piston with corresponding lugs. The reliable mechanism practically does not break, the strength depends on the characteristics of the metal.

- The drive rod closer has 2 pistons for opening and closing the curtain. The elements move from the action of the eccentric shaft. The dimensions of the sliding model are smaller than the toothed one, but the practicality is not inferior.

There are models with articulated or link arms, where rotation is transmitted by a folding arm. They are poorly protected from vandals and protrude ugly perpendicular to the plane of the door.

Mechanisms with a delayed closing allow you to keep the sash open for a period of up to 30 seconds.

Floor standing

The devices are designed to be installed in the floor. They are used for one-sided opening and pendulum-type doors. The mechanisms operate safely and comfortably, while remaining closed from prying eyes. Models are more often produced with the canvas fixed in the open form. They are used at the doors of warehouses, workshops, where it is necessary to carry large things, to carry out airing. Be sure to put in medical institutions, places where people with disabilities pass.

The mechanism is located in an open box.To open, you need to make an effort, the closing is smooth. The floor version works with door leaves up to 1.6 m wide, and the weight should not exceed 160 kg.

Selecting a floor closer according to door parameters:

- weight up to 20 kg, width up to 0.75 m - put model EN1;

- 20 - 40 kg, 0.85 m - EN2;

- 40 - 60 kg, 0.95 m - EN3;

- 60 - 80 kg, 1.1 - EN4;

- 80 - 100 kg, 1.25 m - EN5;

- 100 - 120 kg, 1.4 m - EN6;

- 120 -160 kg, 1.6 m - EN7.

For canvases wider than 1.6 m, an upper and lower closer are installed. Installation of the floor version consists in screwing the necessary places and forming a floor niche.

Hidden

More often put on interior paintings. The second name of the closer is frame. The working mechanism slides from the inside of the body. The model in the form of a cylinder is cut into a wooden canvas, since the device has small dimensions, and the sliding bed is mounted in a box. The movement is transmitted to the sash along a rigid rod.

When choosing, factors are taken into account:

- the weight of the canvas, since devices of a hidden type have different powers, and an incorrect orientation in terms of the magnitude of the force will lead to difficult opening or failure of the closing;

- intensity of door use - each device has a certain resource of work;

- temperature - at rates below -10 ° C, models optimized for this are chosen;

- the thickness of the sash and box - to put the device, you need to deepen it into the canvas.

The hidden mechanism is protected from destruction by vandals and is not visible from the outside. The disadvantages include the significant price and complexity of installation.

Installation instructions are sold with the mechanism. For adjustment, there is a screw for loosening and tensioning the spring, an element for selecting the opening speed.

Varieties of installation schemes

Closing controllers are installed not only on external or internal doors. They are also mounted on wickets or gates. At the entrance structures, they are placed on a canvas and a box inside the opening. There are frost-resistant models, but it is better to save the mechanism from the action of weather factors.

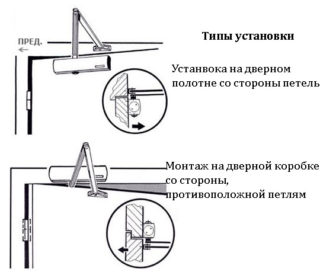

The installation is carried out according to the schemes:

- standard - fixing the device on the canvas, a box is used to attach the lever;

- parallel - mounting parts (corners) are used, the lever is placed in a synchronous direction;

- upper - the device is attached at the top of the bezel, and the lever is placed on the sash.

Often, obstacles in the form of moving objects fall into the opening or the canvas is propped up with stones, wedges. This cannot be done. Sometimes there is a drooping of the sash and friction of the lower part against the floor or landing.

In order for the circuits to work correctly, the adjustment is carried out within the recommended parameters for the desired model. The closers are regularly inspected and the oil is changed if it starts to leak. Regular failure in operation becomes the reason for replacing the device itself.

Standard installation

The standard type of installation of the closer uses 100% of the power of the device. This is important if the weight of the door approaches the permissible standard load of the mechanism. With this scheme, the maximum opening angle of the web is obtained.

In the closed position, the balancing handle is positioned at a 90 ° angle to the door. The method is used if there is room for the lever to turn and the canvas complies with the standard dimensions. The protruding handle spoils the look of the room and catches the eye in narrow hallways and corridors. The mechanism is susceptible to attack by vandals or those who simply wish to hang on the lever.

The standard scheme is not suitable when it comes to a thin-walled door made of aluminum, glass, sometimes the upper crossbar of the sash interferes with the installation of the closer.

Top installation

The method is completely opposite to the standard scheme. A door closer with a lever is placed inside the room, while the hinges are not visible, the canvas opens from itself.The box of the mechanism is placed on the top of the loot, and the lever sole is fixed on the canvas. So you can install a door closer on the entrance door and on internal openings if the standard system cannot be used.

The mechanism uses power that is close to the nominal allowable values, while losing up to 10% of efficiency. The opening angle is within 90-95% of the maximum possible. Ideal for installation on the entrance group of doors, since the internal arrangement saves the mechanism from negative weather factors.

The upper mounting method is used on thin door leaves, since the load falls on the upper box strapping. The disadvantages include the protrusion from the lever, but not outside, but inside the room. The mechanism is also easy to break. The headroom of the door must be of sufficient height so that the body at the top does not interfere with the passage through the opening.

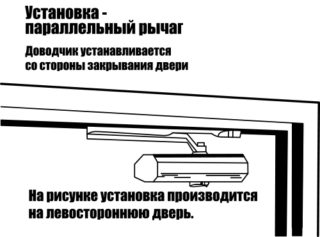

Nonstandard parallel

The top fixing method is suitable for public places where there is a possibility of rough handling and lever breakage. The model looks neat in the opening, in the folded position it is not of interest to vandals. The method is used if a wall or ceiling interferes with the standard installation at an overhead location. Often installed in a version with a vestibule and two doors.

The disadvantages of parallel placement are that the lever cannot use the power to its maximum, and the efficiency is reduced by 25 to 30% than with the standard method. If the parameters of the closer are designed for 100 kg of leaf, it can only work with a sash weighing 70 - 75 kg. The maximum opening angle is much smaller than in the two previous schemes.

DIY door closer installation guide

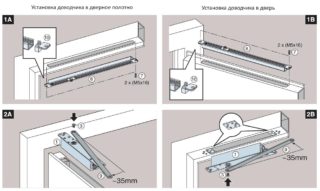

The manufacturers of the return mechanism provide a wiring diagram that is drawn in full size. It is placed on the door to mark the installation. The color marks the door line, the side of the sash with hinges and other markings.

Step-by-step instruction:

- the technological scheme is attached to the door with tape;

- holes are marked with a core or other tool;

- according to the scheme, the closer is oriented so that it becomes an end with screws to the side with hinges;

- fix the box of the device;

- disconnect the lever into two parts, fix the foot of the handle to the canvas;

- the second part of the lever is fixed to the closer.

The adjustable side of the door leaf lever with latches is set 90 ° to the door so that the leaf is brought to an almost buried state. The length of the lever is shortened to provide a slight pressure to engage.

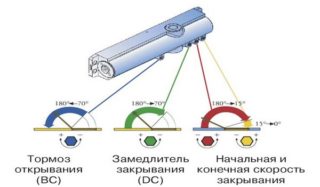

Adjustment and adjustment of the closer

General rules for all screws:

- if rotated clockwise, the closing power and speed will be increased;

- turning counterclockwise reduces force and brakes the belt.

The adjustment is carried out smoothly, do not turn the screws several turns at once. Sometimes ¼ or ½ a turn is enough. If the balance of work is severely disturbed, it will take a long time to restore the initial position. Various elements are used to adjust the closing and the speed of finishing. The screws are rotated little by little until the sash smoothly comes to the closed position.

Features of installing hidden closers

The plate is circled with a pencil, the cylinder is taken out, a recess is cut in the canvas for the bar. After the second insert of the housing, the closure is checked, the corresponding place on the slope is marked. They act as with the previous plate - make a sample to drown.

The bar with the cylinder is attached to the canvas, with pliers, the outer part is pulled from the inner part to the position when a small segment of the chain appears. A retainer is put on, which is fixed in a stretched position. The outer bar is screwed with self-tapping screws to the sample on the slope of the doorway. After that, the retainer is removed, and the work of the closer is monitored.