Doors in a living space are chosen depending on the configuration, the number of leaves, and also take into account the style of the interior. Filling of openings can be ordered in the workshop or purchased ready-made doors in the store. Often, home owners do the installation of interior doors with their own hands in order to save money on the payment of installers. The complex of works differs depending on the material of the canvas and the box.

Types of interior doors by material

The door leaf is a sliding or swing sash, with the help of which the passage to the next room is opened. In the building there may be inserts of glass, decorating lattices, and other decorative details. Canvases by design are solid, prefabricated, paneled or panel board, in some types honeycomb and hollow materials, glued laminated timber serve as a filler.

The types of canvases are distinguished by material:

- fibreboard (fiberboard);

- fine fraction slabs (MDF);

- different types of natural wood.

When choosing, the manufacturer is taken into account, since Chinese manufacturers put low-quality materials, self-assembly is difficult, even if installed according to the instructions and follow the technology.

Fiberboard

The material is used as part of panel boards, when a frame strapping is made of a wooden bar along the perimeter of the sash. Fiberboard with a laminated coating is used, sometimes an untreated version is put under subsequent painting. Wood slats or strips are also added inside the frame to provide strength and rigidity. The market offers for sale about 90% of such paintings from the total sales.

Fiberboard is made using a variety of resins that release harmful formaldehydes when the temperature rises. The material itself does not differ in beauty, therefore it is put in combination with decorative trim. As part of paneled doors, fiberboard is used as filling between transverse imposts.

MDF

Advantages of finely dispersed slabs:

- environmental friendliness of the material;

- strength, rigidity;

- independence of performance from temperature and humidity differences;

- soundproof and heat-insulating qualities.

In the manufacture of MDF, ligin is used, which does not emit harmful components into the air.

Natural wood

Natural material is mounted in inexpensive panel doors in the form of frame bars, more often pine is used for such details. Canvases can be of frame or panel type. The latter type is distinguished by a flat surface, has an original fiber pattern. The canvases can be assembled from separate strips, which are glued with a butt joint, a ledge - a groove. Details are selected according to texture, grinded and polished.

Valuable rocks with a noble texture are used for solid canvases:

- teak;

- hornbeam;

- nut;

- ash;

- oak.

The premium category canvases are harvested using Karelian birch, rosewood, black or ebony Coromandel. Such door installation is made according to individual orders, used in author's design solutions.

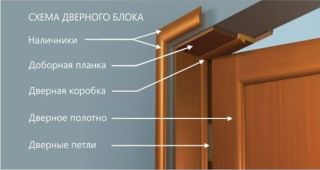

Varieties of boxes

The frame is part of the door block, it is a frame that needs to be fixed in the interior opening. The base is sometimes provided with grooves for fastening platbands. The loot can come with the door leaf or be sold separately. In the second option, compliance with the correct dimensions is required, since if there is a mismatch, the door cannot be inserted into the box.

The material for the box is:

- Fiberboard;

- wood;

- laminated wood.

Most users buy solid wood, but the properties of pressed materials from a quality manufacturer are in no way inferior to natural materials. The decoration of such loops is done with the same material as the main part of the door, so the constructs look like a single whole.

Fiberboard

Fiberboard boxes are cheaper, with rounded and rectangular types being the most common. Products are produced by pressing shavings, sawdust and other wood waste. There are laminated composite varieties, where plastic strips alternate with fibers.

The frames are designed for doors with light weight, since the strength of the door is insufficient for hanging heavy MDF or natural wood panels. The trays can withstand panel and paneled options filled with cellular cardboard, it is better to make such boxes with a threshold in order to increase the rigidity of the structure. The products are distinguished by their beautiful appearance, since there is a decorative finish on the surface.

Untreated wood

Products differ in cost and belong to different categories, but they all differ in reliability. Untreated wood during the installation of the door frame is treated according to the rules with antiseptics, covered with a layer of varnish or painted.

Price segments:

- budget - pine massif;

- average cost - alder;

- elite categories - beech, ash, oak.

They use the technology of splicing small pieces into a common mass in order to get rid of defects in natural material.

Wooden frames are distinguished by their high strength and reliability compared to fiberboard products, therefore they are intended for heavy door leaves. Boxes made of natural raw material require obligatory trimming with platbands after door installation.

Laminated wood

Amy with such a coating can withstand impacts, scratches, and abrasion. The finishing layer imitates the textures of various woods, which give the door block beauty and elegance. The box can withstand loads, so you can put heavy canvases made of solid wood, panel and frame doors with a filler made of wooden beams and trimmed with MDF plates.

Laminated trays do not require finishing, as they have a finished look. This circumstance saves time and does not require the purchase of paint or varnish. The quality of the laminated layer and the method of its application matter. A cheap thin paper coating will not last long, and its scratch resistance is questionable.

Sizes and equipment of canvases

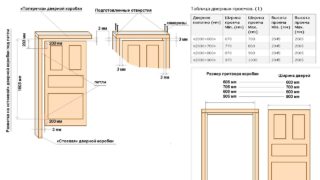

Sample of some sizes:

- canvases are 600, 700 mm wide (bathrooms, pantries, kitchens), 800, 900, 1100 mm (bedrooms, single-leaf entrances to the hall), 2 x 600, 2 x 900 mm (double-leaf door blocks);

- the height of household canvases is in the range of 2 - 2.3 m, while the sash size is 2.071, 2371 m;

- 70 mm are added to the width of a single-leaf leaf, 71 m of a two-leaf leaf, and the size of the loot is obtained - 670, 770 mm ... 1871 mm, etc.

Door blocks are equipped with door closers for automatically pulling the sash, which are available in top, hidden and floor designs. Loops are overhead, mortise, hidden. Handles are placed on the door, which are made in the form of brackets, buttons, compartment made of metal, wood, plastic of various configurations and designs.

Necessary tools and materials for work

It is impossible to install the door with your own hands without high-quality tools, since the main condition is the high accuracy of machining the holes for the hinges, lock and handles.

Before installing the door, you need to prepare tools and accessories:

- electric drill;

- level, tape measure, pencil;

- chisels, screwdrivers, hammer;

- hacksaw for wood, knife;

- spray gun with foam;

- roller, brush, rolling bath.

To seal the cracks, you will need polyurethane foam, cans come in different volumes, they are chosen depending on the size of the gaps around the tray. The installation procedure provides for fastening to the wall with dowels or anchors. For the spacer, bars are prepared in width 3 to 4 cm larger than the inner size of the box.

DIY installation instructions

Work order:

- the frame and door leaf are laid out on a flat floor as they will be located in the wall;

- assemble the box, cut out the grooves for the hinges, try on the canvas;

- install the trap in the opening;

- foaming, placing spacers;

- hang the sash, cut in the lock, put the handles;

- paint, if necessary, fix the platbands.

The direction of opening the door is chosen before assembly so that it is convenient to enter the room and turn on the light. For a bathroom, kitchen, according to safety rules, they always open outward, open the front door inward, and swing in the bedroom, hall, office is done at the request of the owner.

Assembly

Assembly order:

- cut off the racks and the top to the desired size;

- on the floor, twist all parts of the box with self-tapping screws into a frame, pay attention to setting the angles at 90 °;

- apply the sash, mark the loops;

- grooves are drilled for one part of the loop.

In the sash, rectangular recesses are chosen to insert the mating part of the canopy, special attention is required here so that the canvas is not skewed in an upright position.

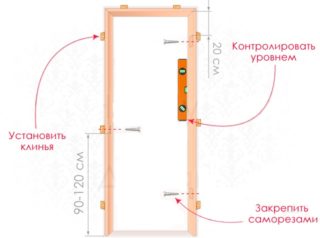

Installation

The box is ideally in the opening if its dimensions are 30 - 60 mm larger than the tray. For larger discrepancies, use wooden wedges to position the box. The vertical parts should be mounted on a level, a plumb line is used for verification. The horizontal top and threshold are also level.

The trap is attached to the walls with dowels so that after screwing in the self-tapping screws, the racks and crossbars do not overtighten and remain in their original position. From the outside of the racks and crossbars, wedges are inserted so that the structure stands firmly, does not move, does not stagger.

The canvas is hung after the foam has dried and the wedges are removed (or their tails are trimmed). The body of the lock is cut into the sash, a hole for the tongue is chosen in the box, the striking plates are placed.

Foaming

The wall and the outer part of the loot are moistened with water before foaming, the foam is squeezed out in between. After the composition has dried (on the second day), the leftovers are cut off with a knife. Take out the spacers, knock out the wedges (if they get in the way).

Finishing

Fiberboard doors with untreated wood frame are to be painted. Oil or acrylic compounds are used, while the former dry for a long time (from 24 hours) and have an unpleasant pungent odor. The box, the canvas are putty with ready-made mixtures for woodworking in order to close up the existing joints, cracks and caps of self-tapping screws.

After drying, sand the surface, primed with adhesive liquids and wait for drying. The paint is applied with a roller, then a brush is used where it was not possible to get it. Re-coat if necessary. Laminated doors and frames do not need to be painted.

Platbands are cut at 45 ° corners using a miter box. Nailed to the tray or use self-tapping screws. Finishing strips are wood, plastic, ceramic, metal.